Striking device for elevating of mode locked shaft component

A toggle device and shaft assembly technology, which is applied in the field of mechanical structures for opening and closing of a rotary die set, can solve the problems of increasing the failure rate, accelerating the wear of the clamping shaft, increasing the weight, etc., to reduce the moment of inertia and centrifugal force, smooth The effect of free lifting and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

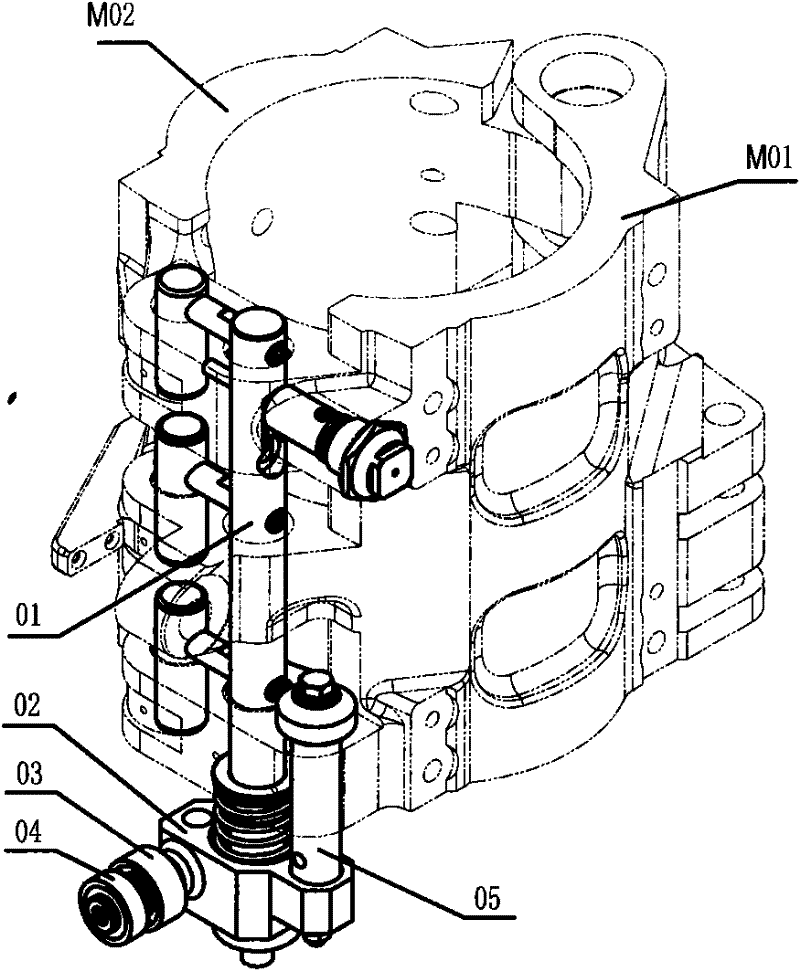

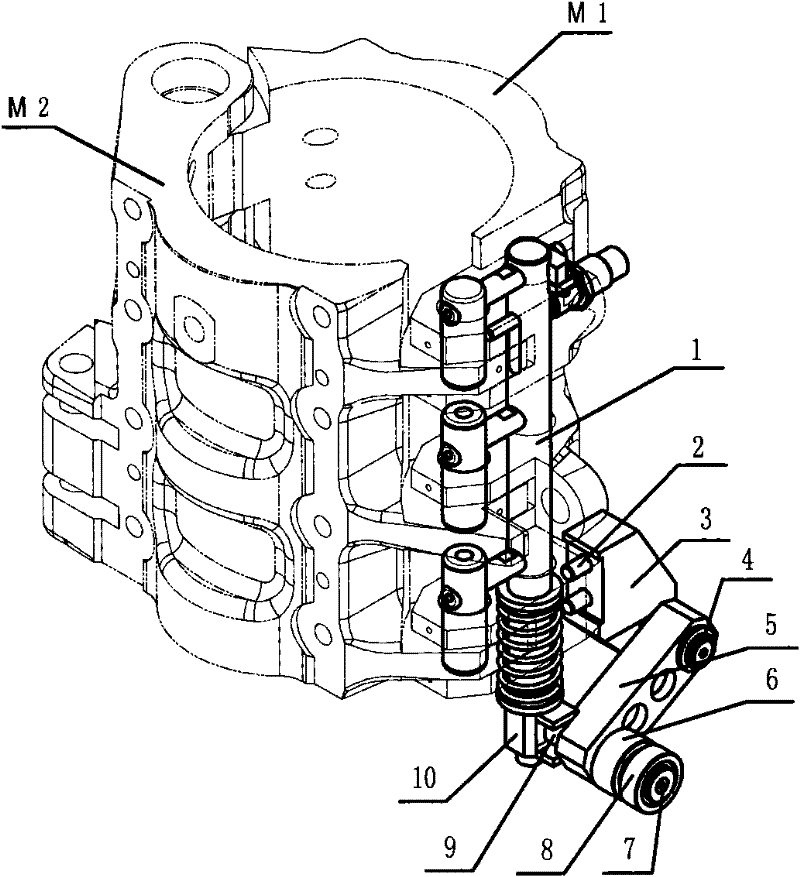

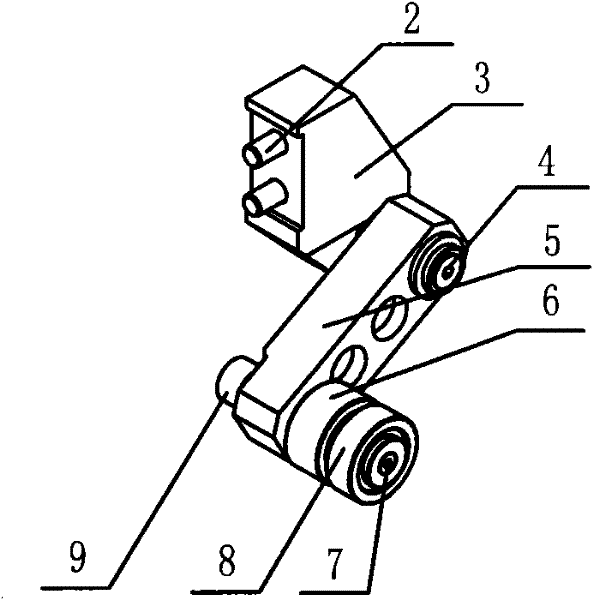

[0017] refer to figure 2 , image 3 , Figure 4 , Figure 5 Shown:

[0018] A toggle device suitable for a fully automatic rotary high-speed blow molding machine to make the clamping shaft assembly (1) go up and down smoothly. And the toggle block (10) controlled by it, the swing arm member includes connecting screw (2), swing arm seat (3), swing arm shaft (4), swing arm (5), roller A (6) , roller shaft (7), roller B (8), toggle wheel (9), the swing arm component is fixed on the formwork M1 by two connecting screws (2) on the swing arm base (3), the swing arm ( 5) is connected together with the swing arm base (3) through the swing arm shaft (4), and can rotate on the swing arm shaft (4), and the other end of the swing arm (5) is equipped with a roller shaft (7), Roller A (6) and Roller B (8) are installed on the roller shaft (7) in turn, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com