Electric booster brake device for vehicle

A technology of electric power boosting and braking devices, which is applied in the direction of automatic starting devices, braking transmission devices, foot-operated starting devices, etc., can solve the problems that the size of the power assist cannot be effectively adjusted, and there is idle travel, etc., so as to avoid idle travel and avoid The effect of poor stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

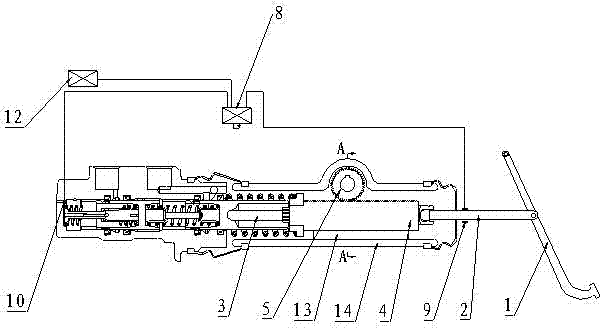

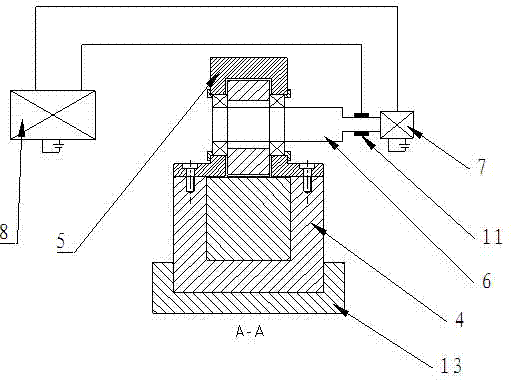

[0017] like figure 1 As shown, a kind of automobile electric power-assisted braking device, pedal 1 is hinged with input force push rod 2, and input force push rod 2 is provided with a speed sensor 9, and speed sensor 9 is connected with electronic control unit 8 on the car. The input force push rod 2 and the ball seat are connected at three points by riveting, and the ball seat and the rack 4 are threaded. The rack 4 below is provided with a rack 4 chute, and the rack 4 and the rack 4 chute are slidably connected and coated with grease to reduce sliding friction. There is also a gear 5 meshing with the rack 4 above the rack 4, the gear 5 is connected with the DC motor belt reducer assembly 7 through the transmission shaft 6, and the DC motor belt reducer assembly 7 is powered by the vehicle battery In operation, the DC motor belt reducer assembly 7 is connected with the electronic control unit 8 . The rack 4 is connected with the output force push rod 3, and a return spring...

Embodiment 2

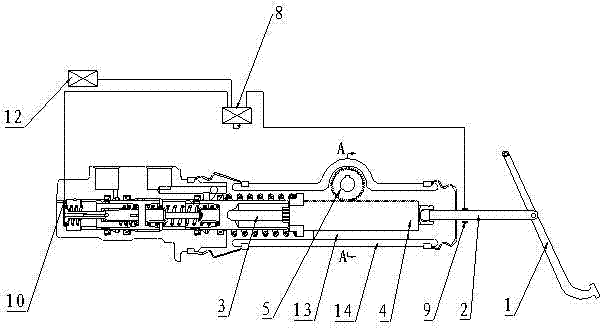

[0023] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that this embodiment is equipped with an ultrasonic distance measuring probe 12 at the front end of the vehicle, and the ultrasonic distance measuring probe 12 is connected to the electronic control unit 8 . When the car is running, the electronic control unit 8 continuously sends instructions to the ultrasonic distance measuring probe 12 to order the ultrasonic distance measuring probe 12 to continuously detect the road condition information in front of the vehicle. According to the pre-programmed program of the electronic control unit 8, when the ultrasonic When the ranging probe 12 detects an obstacle within a certain distance ahead, such as: 50 meters or 20 meters, the electronic control unit 8 automatically starts the braking program, and the electronic control unit 8 commands the DC motor to start. Complete the braking task according to the electric power-assisted brak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com