Inserted steel pipeline connecting structure

A connection structure and interpolation technology, which is applied in the direction of flange connection, pipe/pipe joint/pipe fitting, passing components, etc., can solve the problems of bevel processing at the welding end, complicated processing procedures, and long connecting parts, etc., to achieve Conducive to positioning connection, convenient and reliable welding, and shortened connecting pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

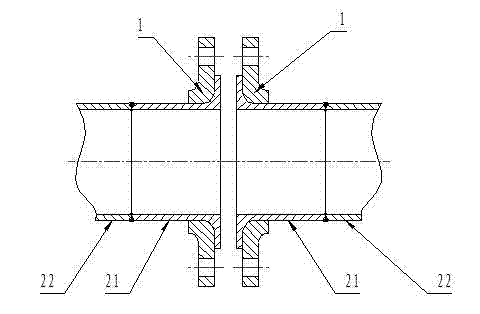

[0024] The existing butt welding ring loose sleeve steel pipe flange is used for the connection between pipes and pipe fittings, and its flanging / flange structure is as follows figure 1 As shown, the butt welding flange is adopted, and its main feature is the sealing connection between the pipe and the flange at the pipe end in the form of butt welding.

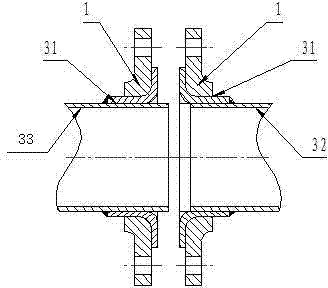

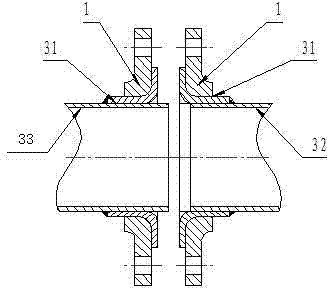

[0025] see figure 2 , the interpolation type steel pipe connection structure of the present invention comprises structurally symmetrical flanging 31 and flange 1 on both sides of the pipe connection, the flanging is composed of a flanging flange and a flanging connecting pipe, the pipes 32, 33 to be connected It is connected with the flanging 31 by inserting, that is, the pipes 32 and 33 are respectively inserted into the flanging connecting pipes on both sides of the connection. The part that one side protrudes out of the flanging joint is equal in length to the part that the other side is indented into the flanging joint....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com