Universal connector

A technology of connectors and outer rings, applied in the direction of adjustable connections, through components, pipes/pipe joints/fittings, etc., can solve the problems of shortening manufacturing and maintenance cycles, and difficult pipe connections, etc., and achieve compact structure, easy installation, and reliability The effect of sealing the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

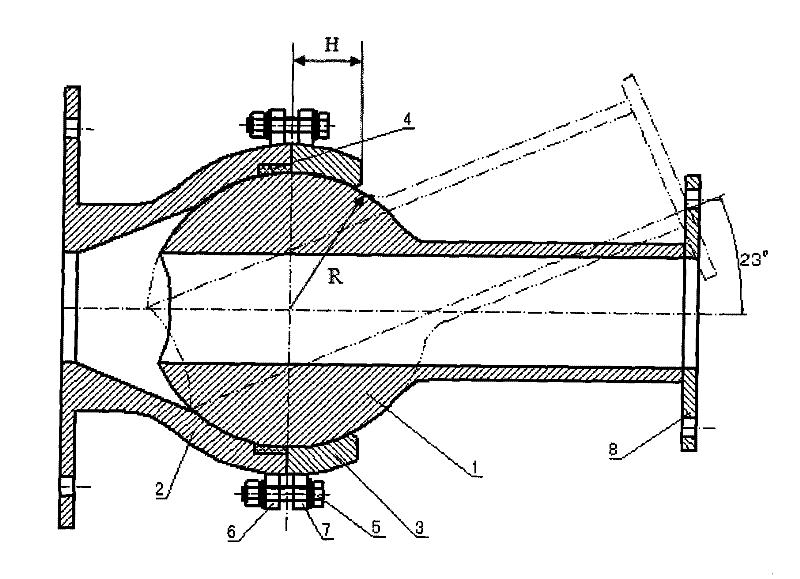

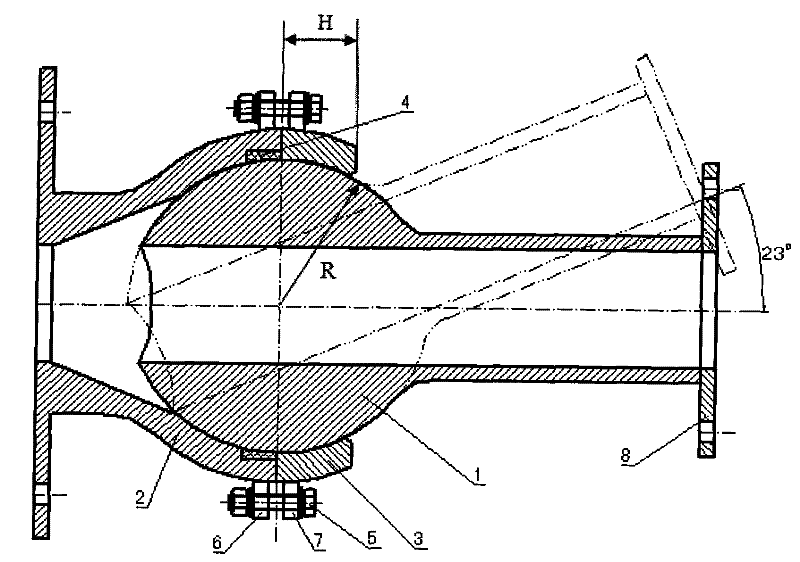

[0009] Among the figure: 1, universal head, 2, left outer ring, 3, right outer ring, 4, sealing ring, 5, bolt, 6, left flange ring, 7, right flange ring, 8, square flange.

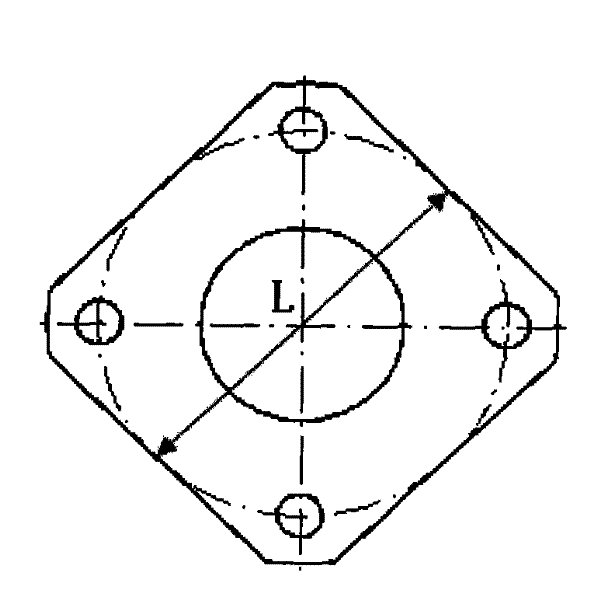

[0010] H: width of right outer ring, R: radius of inner circle of right outer ring, L: side length of square flange.

[0011] Depend on figure 1 , 2 As shown, the universal connector is composed of universal head 1, left outer ring 2, right outer ring 3, sealing ring 4, left flange ring 6, right flange ring 7, bolt 5 and square flange 8; The head 1 is a hollow ball head with a handle, which is composed of a hollow spherical head, a rod and a square flange 8. The spherical head and the rod are connected as one, and the square flange 8 is welded to the universal head 1 rod. The tail end of the head; the left outer ring 2 and the right outer ring 3 are ball tiles with gaps, the connecting flange on the left outer ring 2 is integrated with the ball tile, and the sealing ring 4 is embedded in the inner part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com