Leakage detection device for gas insulated transmission line

A gas insulation and measuring device technology, which is used in measuring devices, fluid tightness testing, and machine/structural component testing. good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, preferred embodiments of the present invention will be described in more detail with reference to the accompanying drawings.

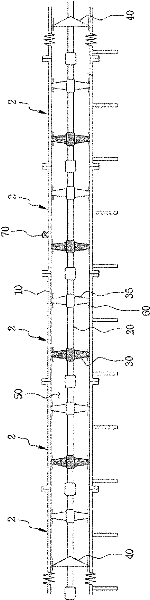

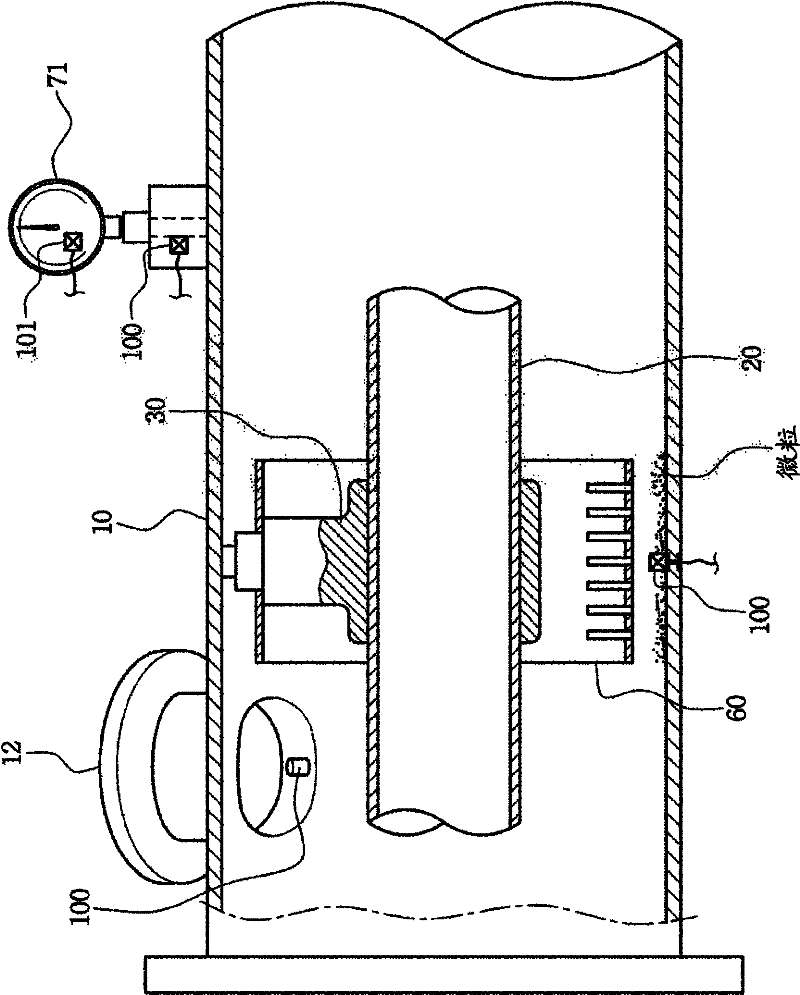

[0024] exist figure 2 A gas leakage measuring device for a gas insulated transmission line according to an embodiment of the present invention is schematically shown in .

[0025] Such as figure 2 As shown, in the case of the gas insulated power line, in the cylindrical outer container 10 , the cylindrical conductor 20 is arranged with a distance from the outer container 10 maintained by the supporting insulator 30 . The insulating space is filled with insulating gas, and a particle trap 60 is arranged in the middle of the line.

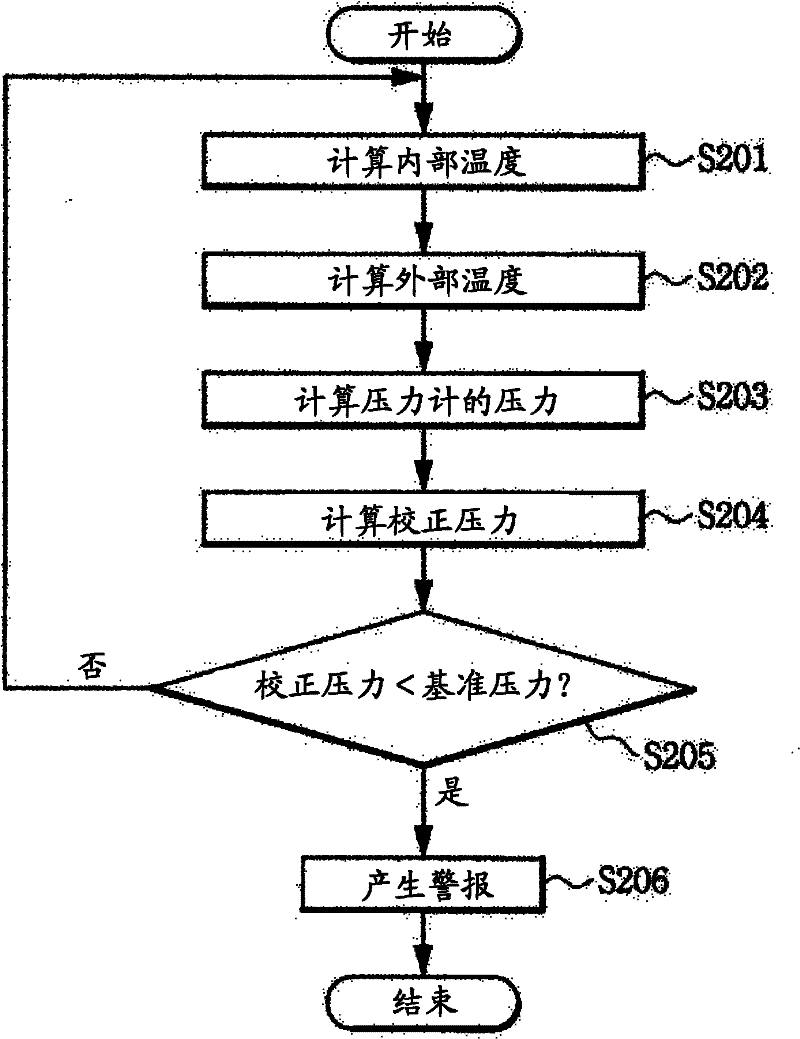

[0026] According to this embodiment, the outer container 10 is provided with a pressure gauge 71 for detecting the pressure of the insulating gas inside the transmission line, and the outer container 10 is provided with an insulating gas temperature sensor 100 for detecting the temperature of the insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com