Positioning method of transverse wave TOFD (Time of Flight Diffraction) defect

A positioning method, transverse wave technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids and other directions, can solve problems such as accurate positioning of workpieces, achieve accurate positioning, high precision, and avoid scattering signal interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention is described in detail below:

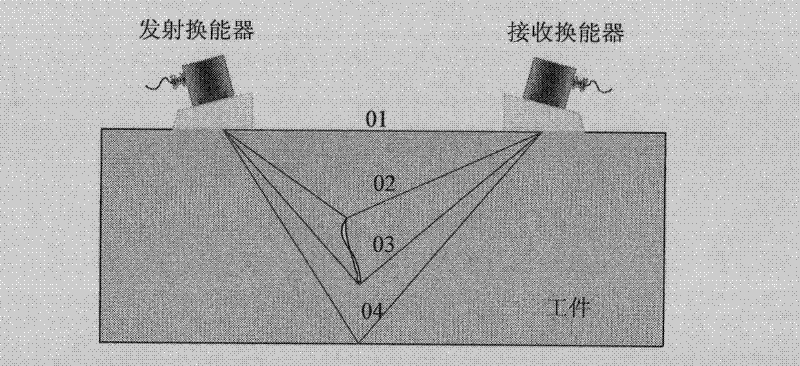

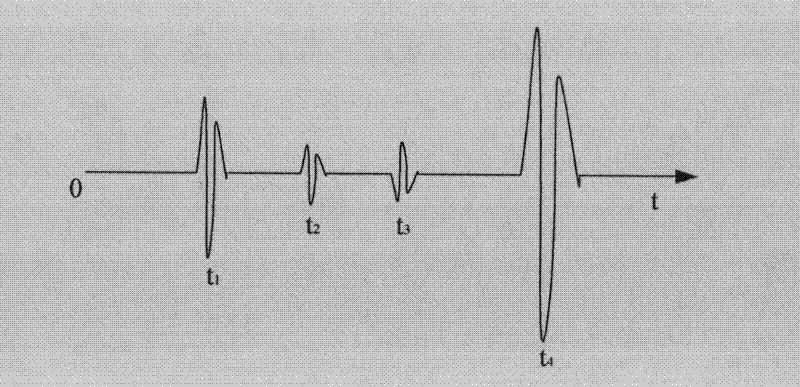

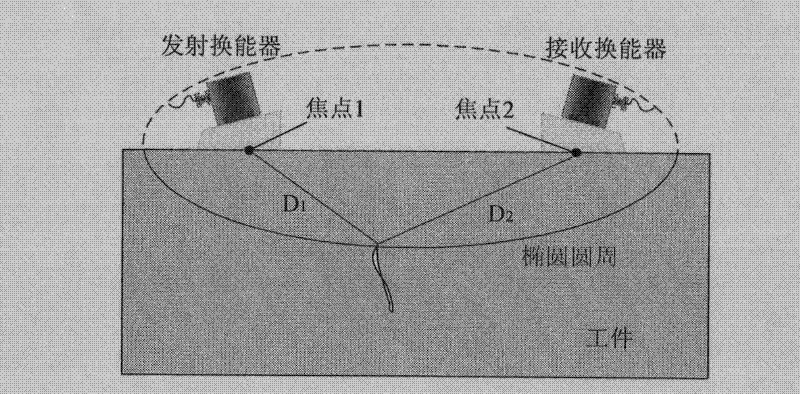

[0028] In order to verify the feasibility of the above-mentioned shear wave TOFD defect location method, a test block containing defects was designed. The aluminum plate test block was artificially flawed by EDM. According to Image 6 As shown in , arrange a pair of shear wave transducers on the surface of the workpiece to be tested, and let the transducers scan along the centerline of the plate, and the obtained A-scan signal and B-scan image are as follows: Figure 7 As shown, the shear wave scattering signal in the B-scan image is strong, and the longitudinal wave scattering signal is relatively weak, but it can still be identified. Then, using the above-mentioned shear wave TOFD defect positioning method, we conduct a positioning study on the artificial defect and compare it with its actual position. The measurement results show that the defect location error is less than 3%, which veri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com