Method for uniformly and chemically gold-plating ITO wiring on capacitive touch screen

A capacitive touch screen, chemical gold plating technology, applied in liquid chemical plating, electrical digital data processing, metal material coating technology and other directions, can solve the problems of gold plating falling off, inconsistent gold plating thickness, time difference, etc., to achieve uniform gold plating thickness and transmission. good signal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

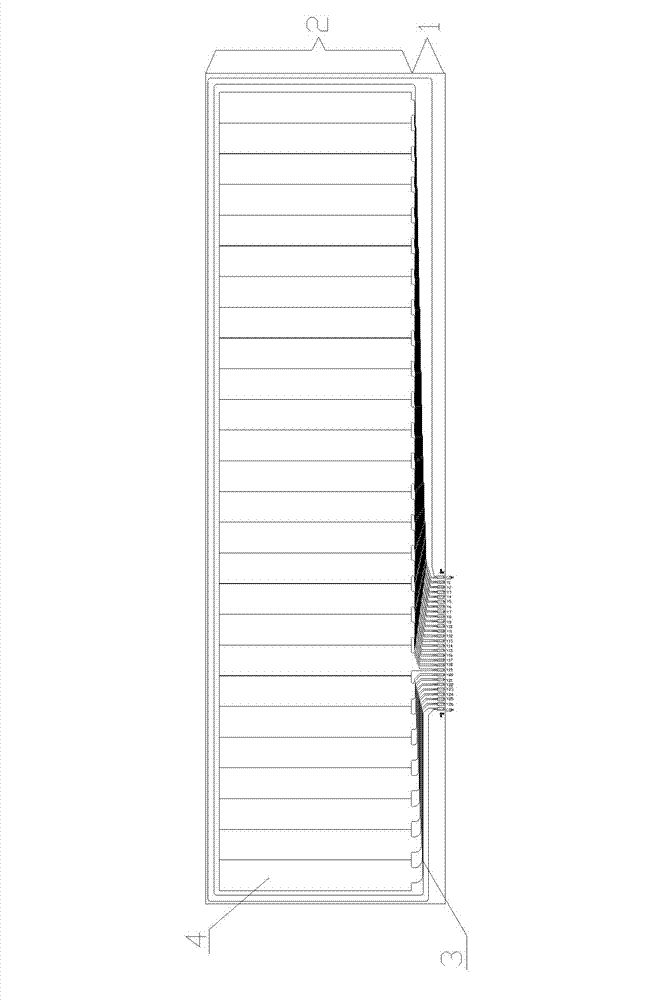

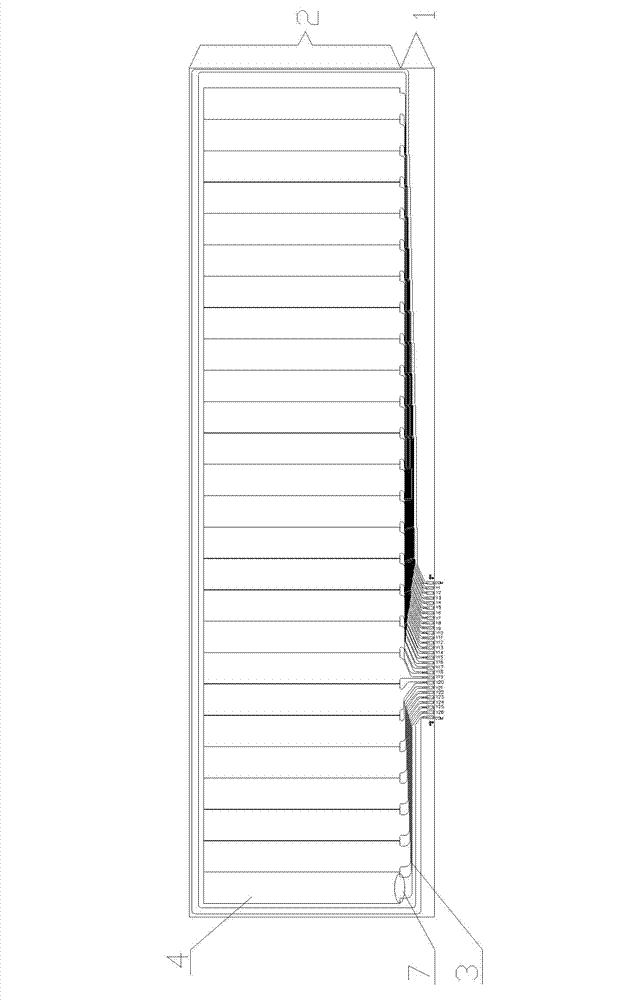

[0027] Specific embodiment one, see figure 1 , figure 2 : the original part to be gilded 1 (see figure 1 ) The length of the single trace 3 is thin, and now the part to be gold-plated is thickened (see 1 figure 2 ) of a single trace 3, to ensure that the area ratio of the trace area of each trace to the single X / or Y direction sensing electrode 4 connected to the corresponding non-gold-plated part 2 is greater than 1%; after that, through chemical nickel plating, chemical The gold-plating process gold-plates the traces of the gold-plated part 1 of each touch glass, and the thickened part is located at the connecting terminal line part 7 between a single trace 3 and a single X / or Y-direction sensing electrode 4 .

specific Embodiment 2

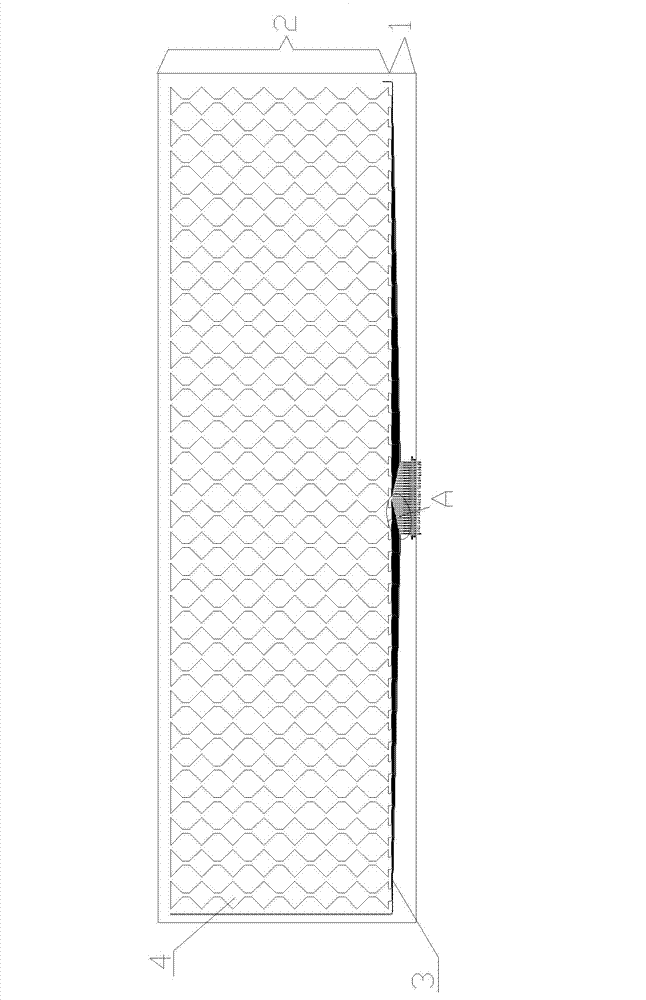

[0028] Specific embodiment two, see image 3 , Figure 4 , Figure 5 , Figure 6 : Extend the length of a single trace 3 of the part 1 to be gold-plated, and ensure that the ratio of the trace area of each trace 3 to the area of the single X / or Y-direction sensing electrode 4 connected to the corresponding non-gold-plated part 2 is greater than 1 %; Specifically, to extend the length of the chamfered transition area of the single trace 3 of the part to be gold-plated 1, the Figure 4 The rounded transition in 5 becomes Figure 6 Angled slash transitions in 6.

specific Embodiment 3

[0029] Specific embodiment three, see Figure 7 , Figure 8 : Auxiliary wiring 8 is etched in the non-touch screen area of the ITO glass, and the area ratio of the wiring 3 of the part to be gold-plated 1 and the corresponding non-gold-plated part 2 connected to the single X / or Y-direction sensing electrode 4 does not exceed 1%. The trace 3 is connected to the auxiliary trace 8, and the total area of the connected trace 3 and the auxiliary trace 8 is greater than 1% of the area of the single X / or Y direction sensing electrode 4 connected to the corresponding non-gold-plated part 2, After the electroless nickel plating and electroless gold plating are completed, the area of the auxiliary wiring 8 is cut off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com