Coil winding device

A winding device and coil technology, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of messy and uneven coils and low efficiency of winding devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

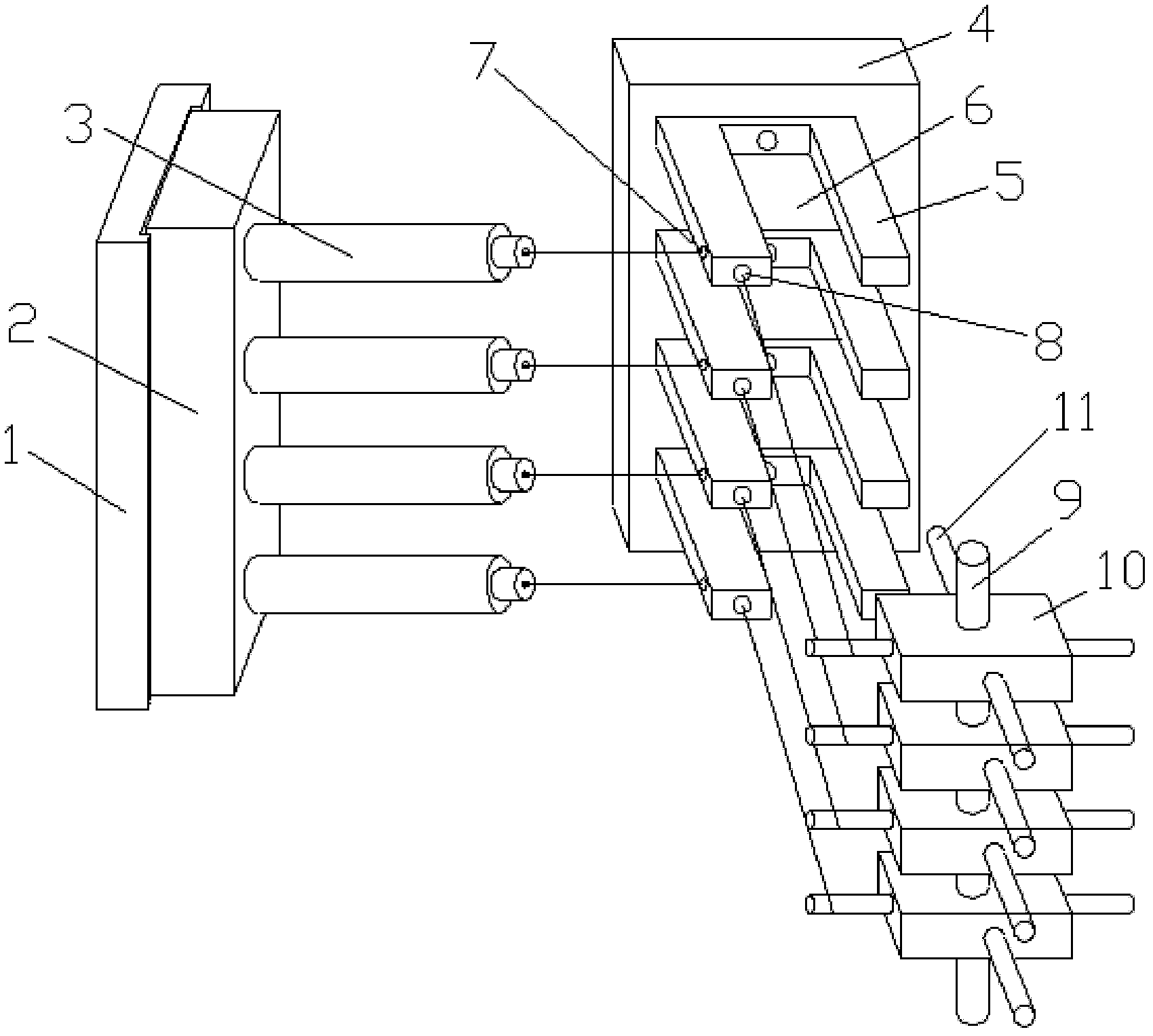

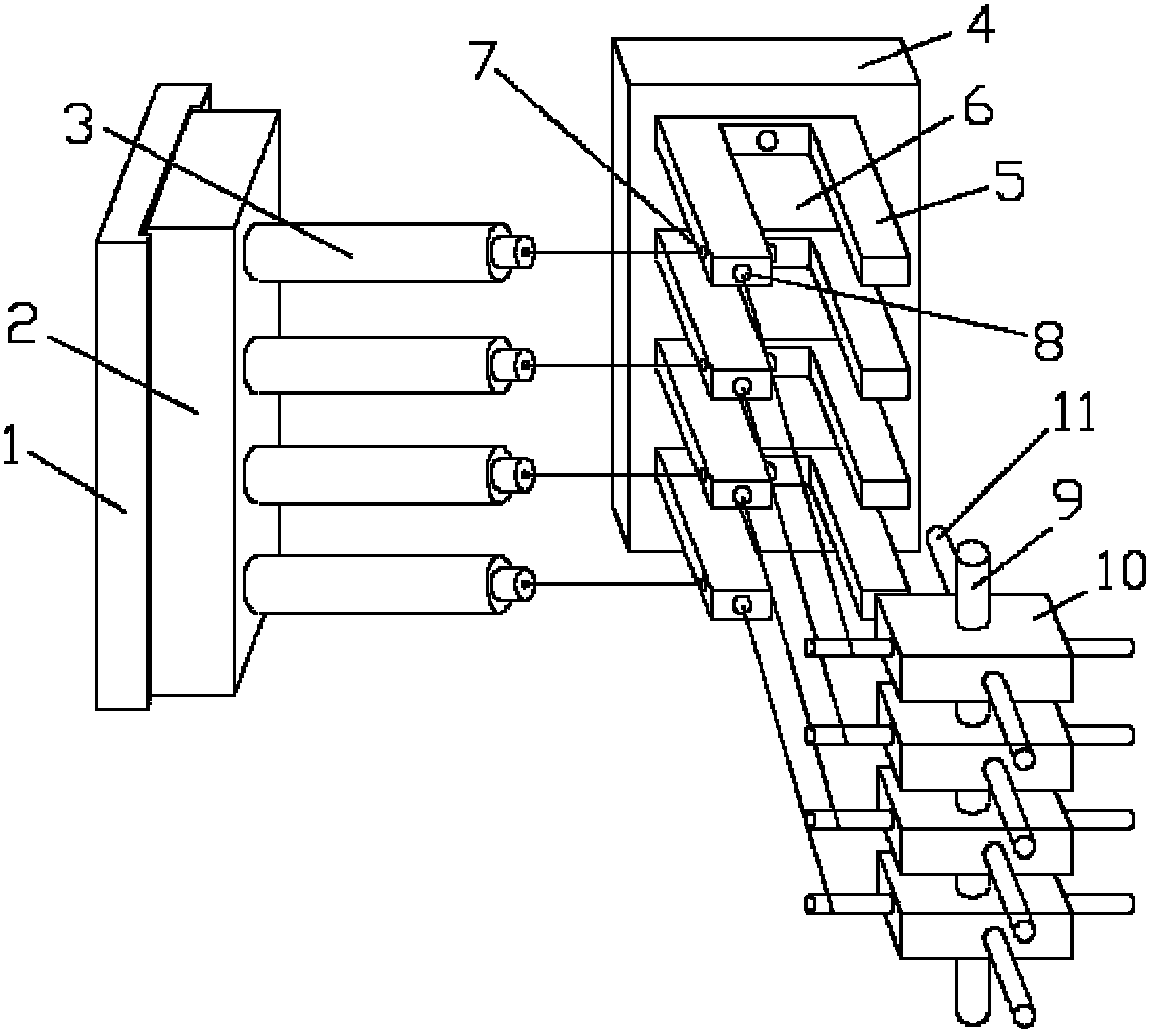

[0010] A coil winding device, including a wire feeding mechanism, a tensioning mechanism, and a wire winding mechanism arranged on a platform, the wire feeding mechanism includes a wire feeding seat 1, and is vertically slidably installed on the vertical seat surface of the wire feeding seat 1 The wire feeding box 2 on the top, the wire feeding box 2 is provided with a plurality of horizontal wire feeding heads 3 perpendicular to the vertical seat surface of the wire feeding seat 1;

[0011] The tensioning mechanism includes a vertical tensioning seat 4, and a plurality of tensioning cards 5 are installed on the vertical seat surface of the tensioning seat 4. The tensioning cards 5 are frame-shaped structures, and the tensioning cards 5 pass through the frame edge of the rear end. Rotate and install on the vertical seat surface of the tensioning seat 4, and the front frame edge of the tensioning card 5 is disconnected to form a bayonet 6, from the side frame edge of the tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com