Feeding machine capable of expanding material positions

A feeder and material level technology, applied in the direction of conveyors, conveyor objects, vibrating conveyors, etc., can solve the problems of inability to expand material level, poor mixing and positioning accuracy, single specification, etc., to achieve convenient expansion of material level , Reduce labor intensity and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

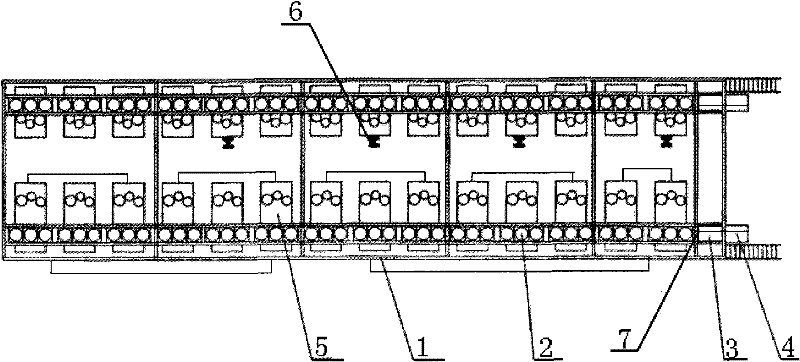

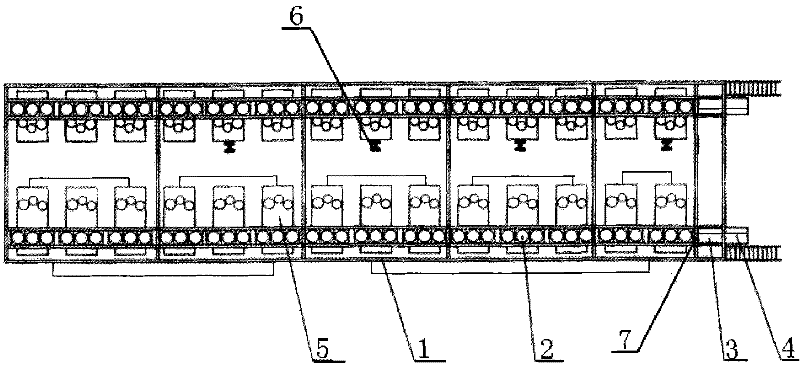

[0011] Such as figure 1 As shown, the feeding machine with expandable material level according to the present invention includes a frame main body 1, a hopper 2, a shifting mechanism 3 and a lifting mechanism 4, and the outer end of the frame main body 1 is equipped with a hoist 4, which is located The two ends of the inner side of the frame main body 1 are respectively provided with shifting mechanisms 3, and the lower side of the shifting mechanism 3 is provided with a number of hoppers 2, and the bottom end of each hopper 2 is correspondingly provided with a vibrating plate 5, and each vibrating plate 5 corresponds to the position of the hopper 2; one side of the vibrating plate 5 is provided with a number of shooting switches 6, and the shifting mechanism 3 is provided with a material door 7. When working, the shift mechanism 3 is at the material receiving position and its material door 7 is closed, and each hopper 2 performs cyclic work. When the shift mechanism 3 is open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com