Corner roller for turning device of belt type conveyor

A technology of belt conveyor and turning device, which is applied to conveyor objects, transportation and packaging, rollers, etc., can solve the problems of large local stress of conveyor belt and friction damage of conveyor belt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

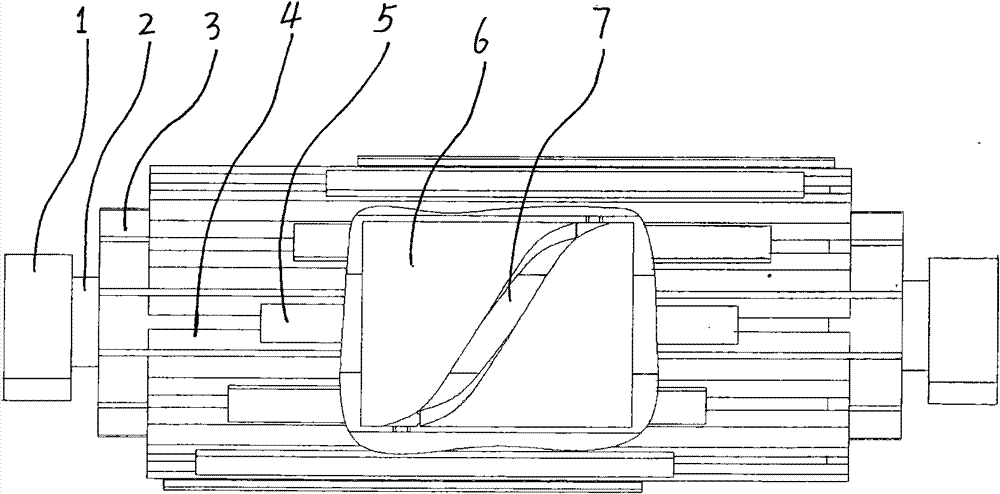

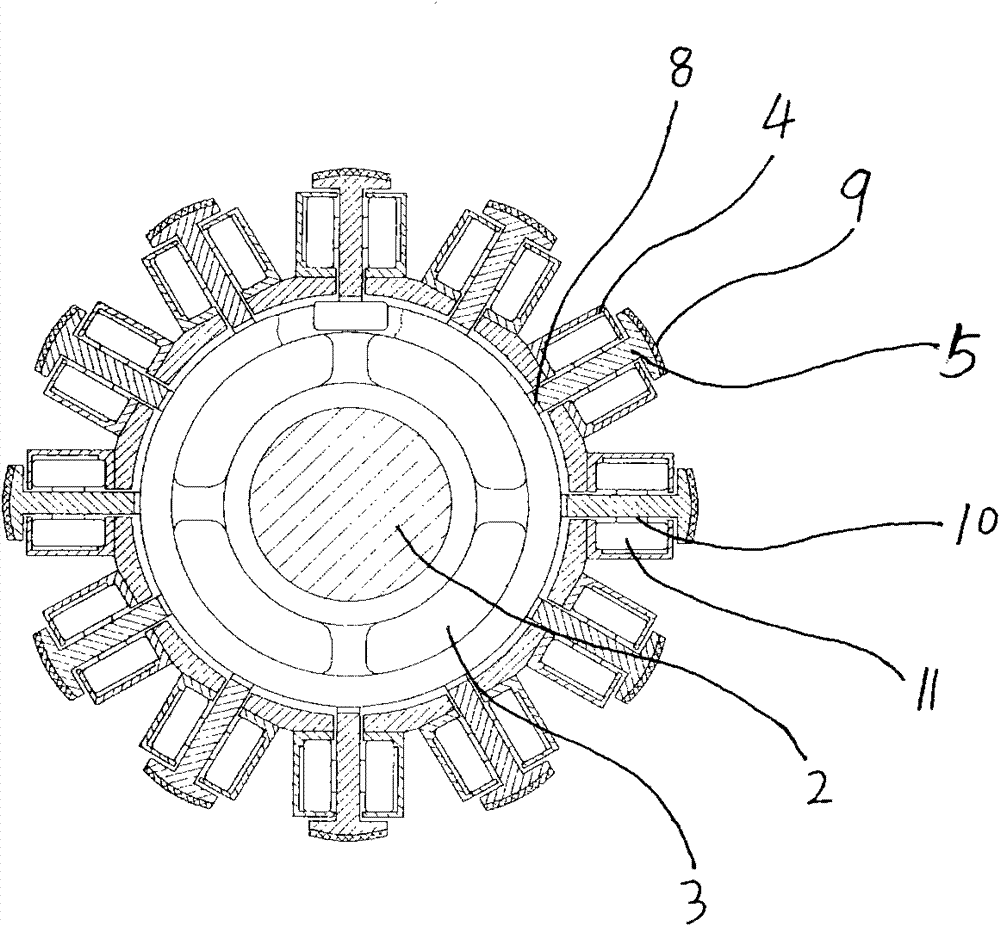

[0010] Depend on figure 1 , figure 2 It can be seen that the present invention includes: a shaft frame 1 , a fixed mandrel 2 , a rotating cylinder 3 , a guide rail 4 , a conveyor belt support 5 , and a hollow cylindrical cam 6 . The fixed mandrel 2 is fixed by the shaft brackets 1 at both ends, the fixed mandrel is fixed by the shaft brackets and cannot rotate, and the rotating cylinder 3 is supported on the fixed mandrel 2 coaxially. A hollow cylindrical cam 6 is arranged between the rotating cylinder 3 and the fixed mandrel 2, the hollow cylindrical cam is concentrically fixed in the middle of the fixed mandrel 2, the hollow cylindrical cam is fixed relative to the fixed mandrel, and the rotating cylinder 3 is fixed relative to the fixed center. The shaft can be turned. An oblique closed-loop cam groove 7 is arranged on the hollow cylindrical cam 6, and a number of guide rails 4 are evenly distributed in the axial direction around the surface of the rotating cylinder 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com