PH-controlled polyolefin breathable film composition and method for preparing composition particles

A technology of breathable film and composition, applied in the field of pH-controllable polyolefin breathable film composition, which can solve the problems of high pH of film products and human health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Put 60kg of calcium carbonate (particle size 2-4μm) in a high-speed mixer (temperature 125±5°C), add 0.6kg of stearate dispersant, stir at 1500r·p·m for 10 minutes, then add 2kg of organic acid Materials, after stirring at high speed for 10 minutes, add 15kg of low-density polyethylene and 30kg of linear low-density polyethylene. After the high-speed mixer mixes evenly at a low speed, it is fed into a two-stage twin-screw extruder for extrusion, pelletizing, drying, and packaging.

Embodiment 2

[0035] Put 50kg of calcium carbonate (particle size 1-3μm) in a high-speed mixer (temperature 125±5°C), add 0.4kg of stearate dispersant, stir at 1500r·p·m for 10 minutes, then add 4kg of organic acidic materials 10kg of low-density polyethylene, 27kg of linear low-density polyethylene, and 8kg of high-density polyethylene were added after high-speed stirring for 10 minutes. The high-speed mixer mixes evenly at a low speed and feeds it into a two-stage twin-screw extruder for extrusion, pelletizing, drying, and packaging.

Embodiment 3

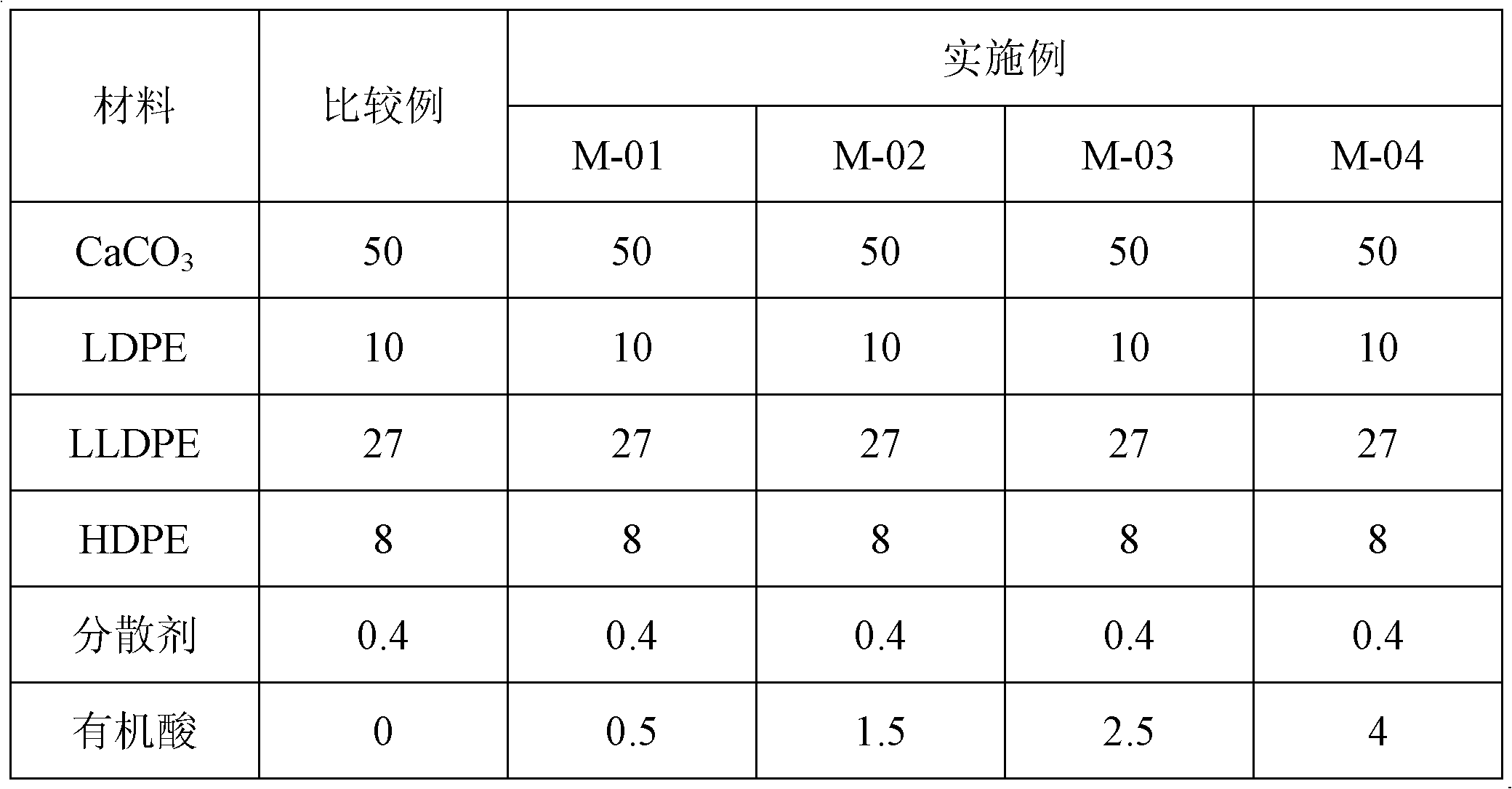

[0037] According to the same processing conditions as in Example 2, organic acid materials with different proportions were used to prepare pH-controllable polyolefin breathable film compositions, and the compositions were prepared through T-die breathable films M-01, M-02, M-03, M -04, see Table 1. Film weight 30g / m 2 , stretch ratio 1.86. The physical and mechanical properties were measured and listed in Table II.

[0038] Table I:

[0039]

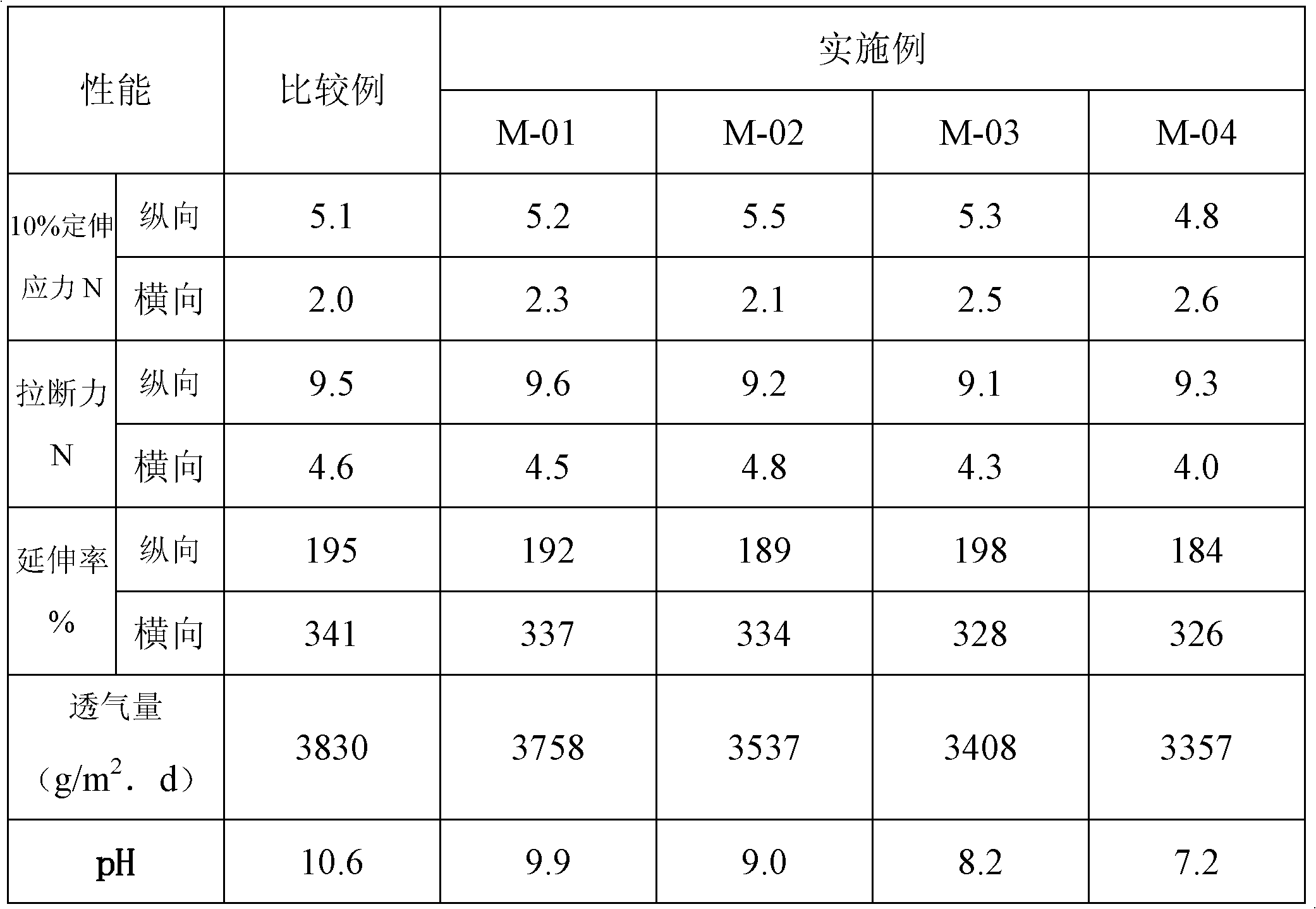

[0040] Table II:

[0041]

[0042] From the results of the examples in Table 2, it can be concluded that the addition of organic acidic materials can effectively adjust the acidity and alkalinity of the polyolefin breathable film, and has little effect on the physical and mechanical properties of the polyolefin breathable film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com