Method for promoting growth of GOSS textures of silicon steel strips by using pulse current

A pulsed current and high-frequency pulsed current technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of low efficiency and high energy consumption, and achieve the effects of low energy consumption, reduction of oxidation degree and production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 : The high magnetic induction cold-rolled silicon steel strip with a Si content of 3% is processed, with a width of 30mm and a thickness of 0.3mm.

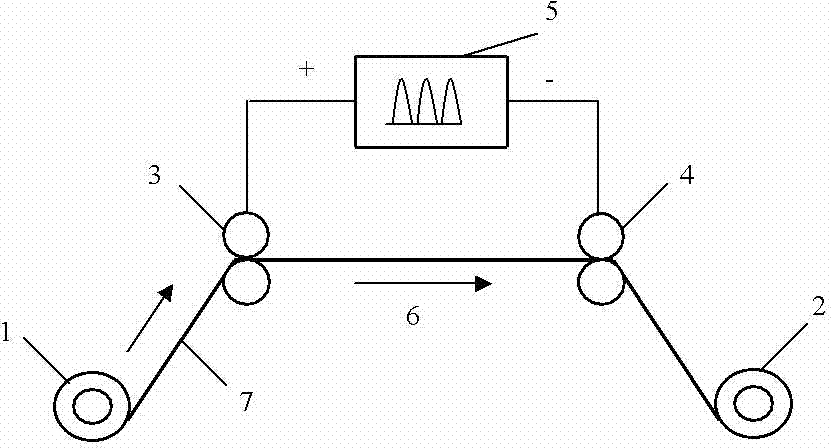

[0041] refer to figure 1 , the continuous silicon steel strip 7 is driven by the unwinding and rewinding devices to transmit at a speed of 2m / min in the direction of the arrow 6, and the positive and negative electrodes of the pulse power supply 5 are respectively made from the conductive wheels 3 and 4 (conductive wheels) made of copper nickel-clad layers. The diameter is 100mm, and the distance between the electrification segments is 150mm) and is connected to the electrification area segment of the moving silicon steel strip 7 for electrical stimulation. is 300Hz, and the peak value of the current density is 120A / mm 2 , the power-on time is 8 seconds.

[0042] The experiment found that, compared with the cold-rolled silicon steel strip treated by unidirectional high-energy pulse current electrical stimulatio...

Embodiment 2

[0045] Example 2 : The high magnetic induction cold-rolled silicon steel strip with a Si content of 3% is processed, with a width of 30mm and a thickness of 0.3mm.

[0046] refer to figure 1 , the continuous silicon steel strip 7 is driven by the unwinding and rewinding devices to transmit at a speed of 2.5m / min in the direction of arrow 6, and the positive and negative electrodes of the pulse power supply 5 are respectively connected from the conductive wheels 3 and 4 made of copper nickel-clad layers. The electrified region segment of the moving silicon steel strip 7 was subjected to electrical stimulation treatment. The pulse width of the unidirectional high-energy pulse current applied to the electrified region segment of the silicon steel strip was 85 μs, the frequency was 700 Hz, and the peak value of the current density was 138 A / mm. 2 , the energization time is 8 seconds, and the surface temperature of the silicon steel strip is measured to reach 850 ℃.

[0047] Expe...

Embodiment 3

[0049] Example 3 : A high magnetic induction cold-rolled silicon steel strip with a Si content of 3% is processed, with a width of 30 mm and a thickness of 0.3 mm.

[0050] refer to figure 1 , the continuous silicon steel strip 7 is driven by the unwinding and rewinding device to transmit in the direction of arrow 6 at a speed of 2m / min. Pulse power supply 5 adopts high-frequency switching pulse power supply, the output waveform is rectangular wave, the frequency is 15-30KHz, and the voltage is 2-12V. The positive and negative poles of the high-frequency switching pulse power supply are respectively connected to the electrified area section of the moving silicon steel strip 7 from the conductive wheels 3 and 4 made of copper nickel-clad layers, and a high frequency of 30KHz and 7.2V is applied during the electrical stimulation treatment. The pulse voltage is applied to the electrified area of the silicon steel strip, the electrification time is 5 seconds, and the surface t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap