Method of building a hybrid tower for a wind generator

一种混合塔、混凝土结构的技术,应用在风力发动机的装配、安装/支撑风力发动机的配置、风能发电等方向,能够解决施工进度延误、困难、影响等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

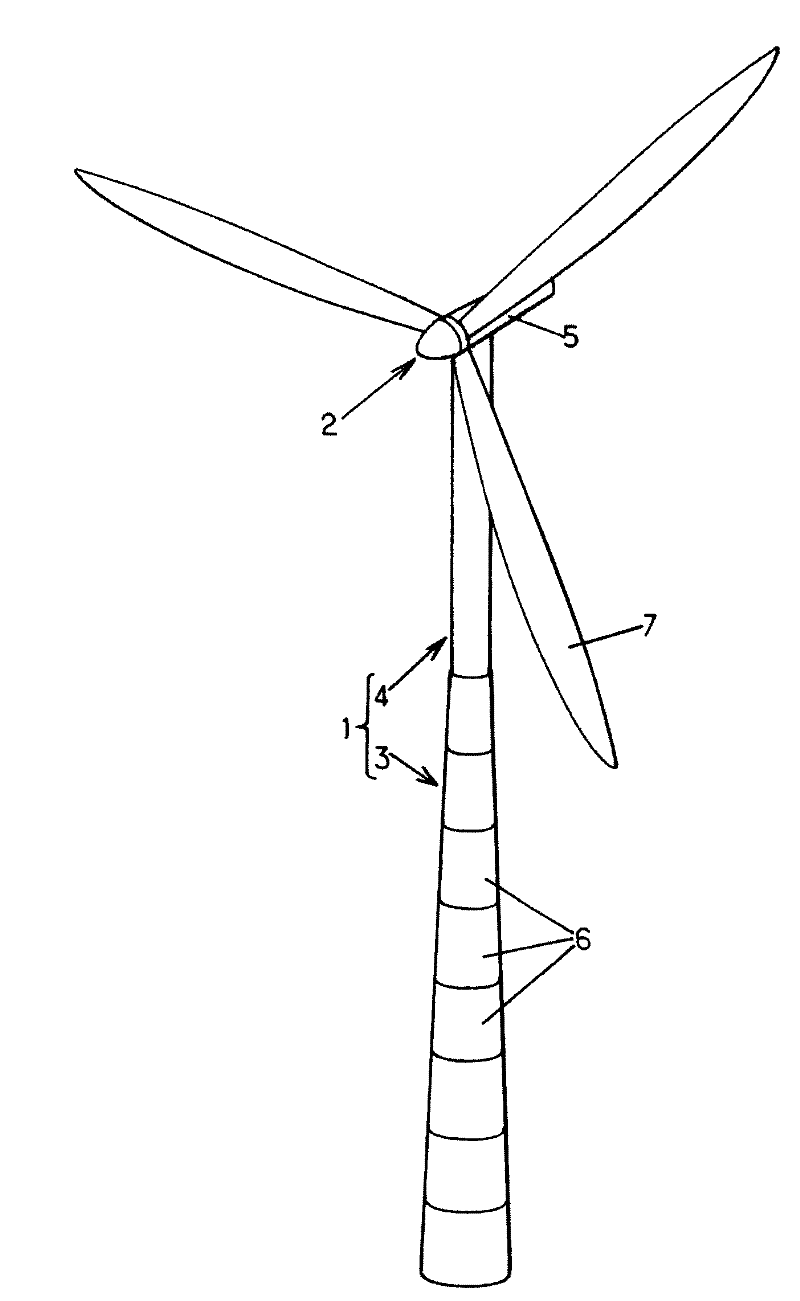

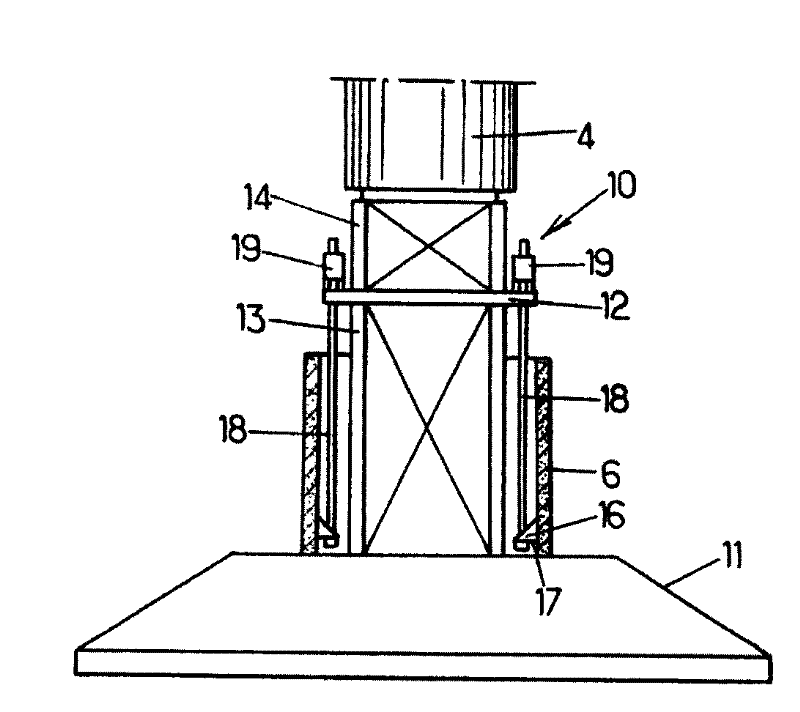

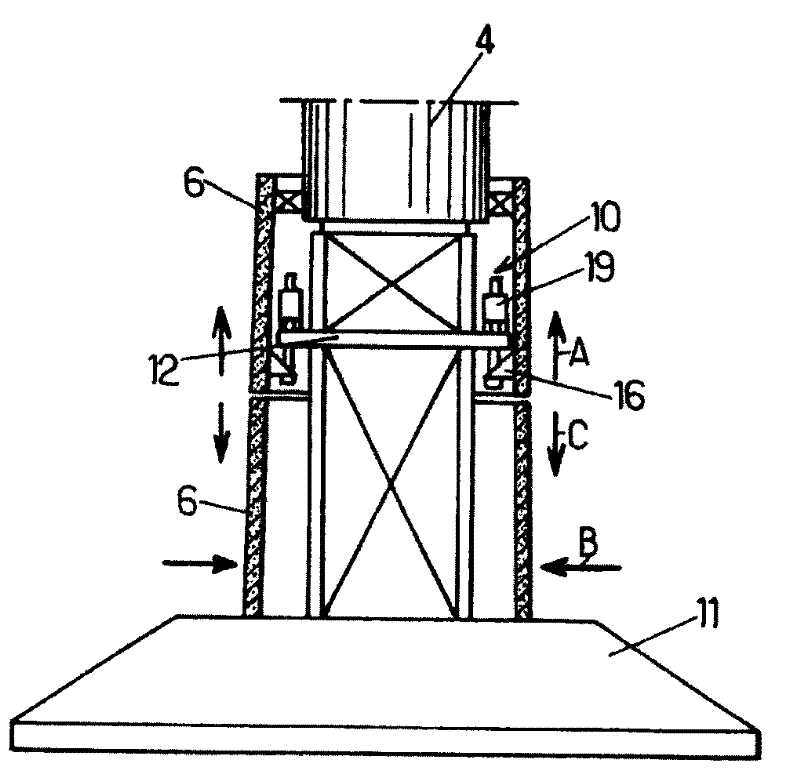

[0027] like figure 1 As shown, a hybrid tower 1 of a wind turbine 2 has a lower part of a concrete structure 3 and an upper part of a metal mast 4 . The nacelle 5 of the wind turbine 2 is mounted on top of the metal mast 4 . The metal mast 4 can be made of one or several sections of cylindrical shaped steel assembled by bolting or welding.

[0028] In the embodiment shown in this figure, the concrete structure 3 comprises superimposed assemblies 6 assembled on site from precast concrete elements. The concrete structure 3 is generally conical, the cone angle remaining constant over its entire height. It is also possible to have a cylindrical concrete part above the cone if it is desired to maintain a constant distance between the tower wall and the rotor blades 7 of the wind turbine 2 . exist figure 1 In the example described, the cone has a circular base. It should be noted that various other shapes can also be used, such as a pyramid with a constant angle, which minimize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com