Method and tool for measuring and trimming steam sealing radial gap of steam turbine set

A technology of radial clearance and steam turbine unit, which is applied in the direction of mechanical clearance measurement, mechanical equipment, engine components, etc., can solve problems such as errors, different judgments, and greater influence of professional skills, so as to improve efficiency, enhance safety, and avoid The effect of excessive gap deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

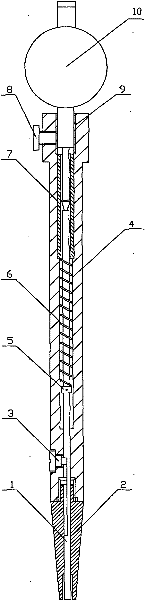

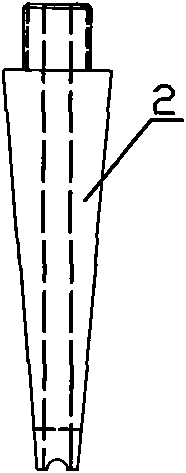

[0047] Such as figure 1 As shown, the steam seal gap measuring ruler for measuring in the present invention refers to: it includes a measuring rod 4 that plays a structural connection role, and a dial gauge 10 is arranged on the upper end of the measuring rod 4, and the dial gauge 10 can be measured The actual height of the object is displayed by the hands. The measuring head 2 is arranged on the upper end of the measuring rod 4, and the measuring head 2 plays a role of determining the measurement reference positioning for the measured object. Wherein, a through hole is arranged in the measuring rod 4, a wire sleeve 7 is arranged on the upper part of the through hole, and a measuring needle 1 is arranged in the wire sleeve, and the top of the measuring needle 1 is connected with the dial indicator 10, so that the measuring needle 1 transmits the height of the measured object to the dial indicator. sub-table 10. The middle part of the measuring needle 1 is covered with a spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com