Gas turbine with securing plate between blade base and disk

一种燃气涡轮机、叶片根部的技术,应用在叶片的支承元件、机械设备、发动机元件等方向,能够解决蜗轮叶轮盘构成复杂、修理麻烦、高结构开支等问题,达到可靠轴向固定、降低重量、便于加工的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

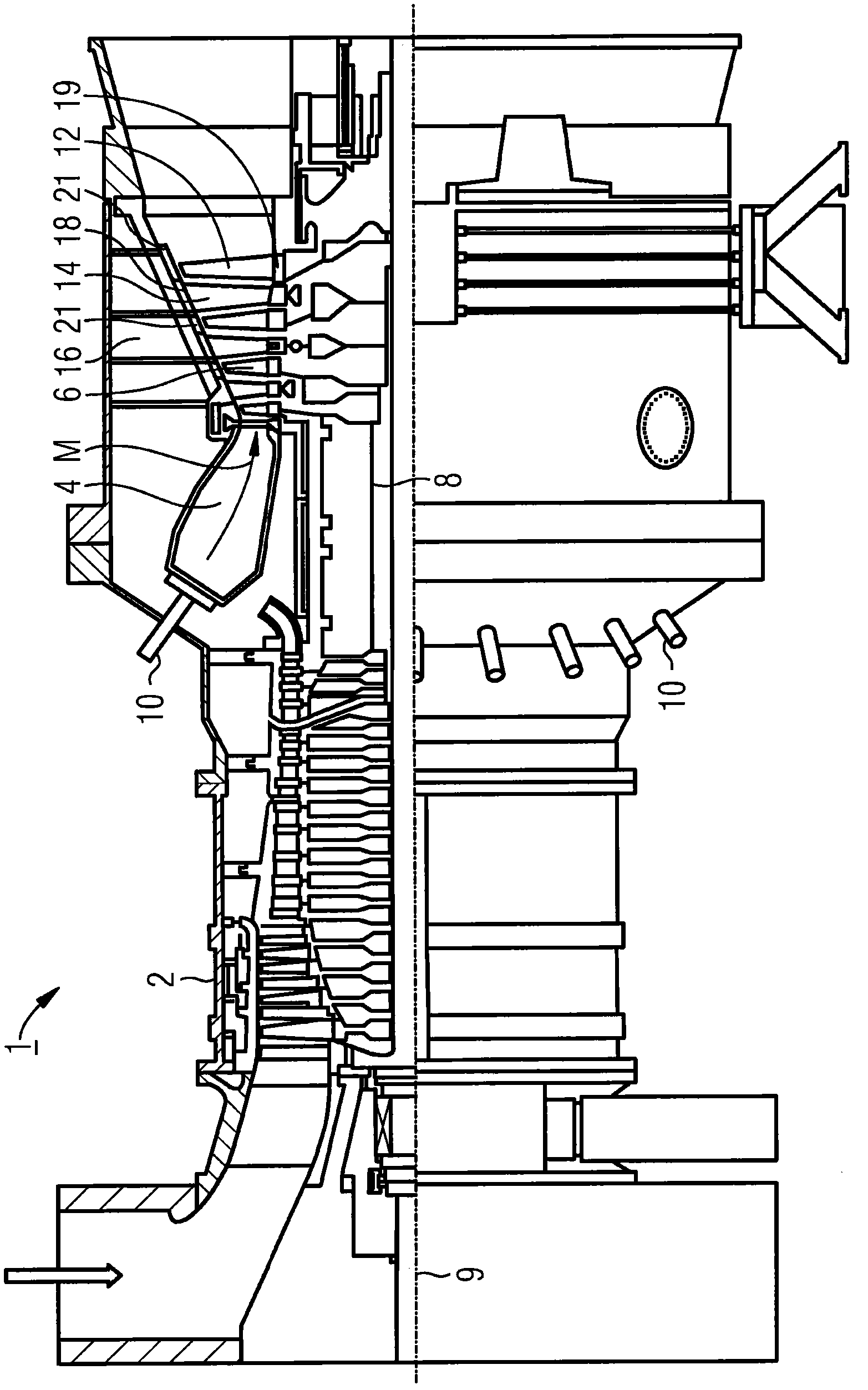

[0029] figure 1 The gas turbine 1 has a compressor 2 for combustion air, a combustion chamber 4 and a worm gear unit 6 for driving the compressor 2 and a generator or driven machine not shown. For this purpose, the worm gear unit 6 and the compressor 2 are arranged on a common worm gear rotor 8 , also referred to as a turbine rotor, to which a generator or driven machine is also connected and which is mounted rotatably about a central axis 9 . The combustion chamber 4, which is designed in the form of an annular combustion chamber, is equipped with a plurality of burners 10 for burning liquid or gaseous fuels.

[0030] The worm gear unit 6 has a plurality of rotatable rotor blades 12 connected to the worm gear rotor 8 . The rotor blades 12 are arranged in the form of a rim on the worm gear rotor 8 and thus form a plurality of rotor blade rows. The worm gear unit 6 also includes a plurality of fixed guide vanes 14 which are likewise fastened in the form of a rim to a guide va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com