Method and device for eliminating shutdown impact of vibration sieve

A technology for eliminating vibration and vibrating screen, which is applied in chemical instruments and methods, filter screens, solid separation, etc. It can solve the problems of damaged vibration mechanism and high failure rate of equipment, and achieve the effects of high shock absorption accuracy, reduced faults, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

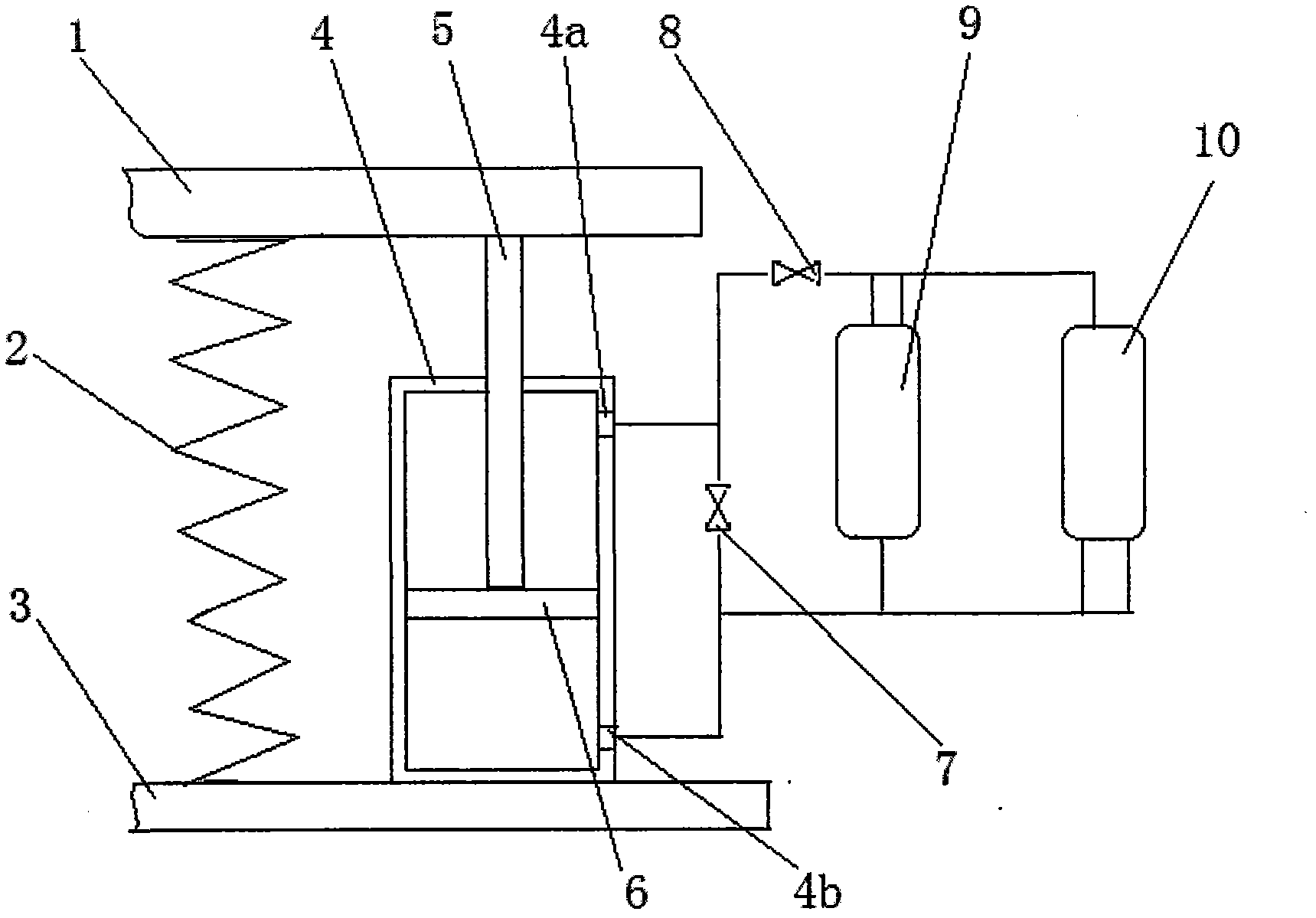

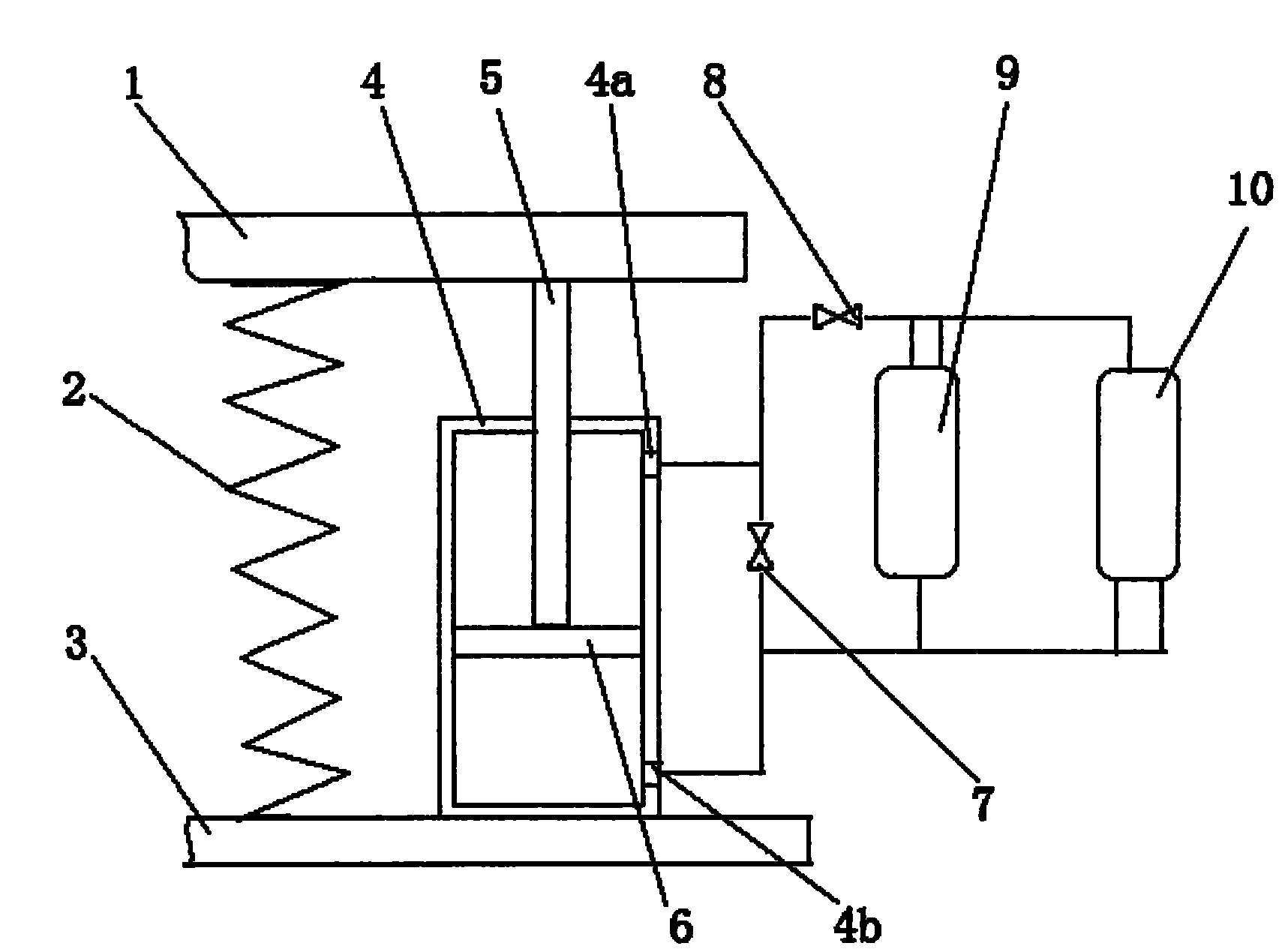

[0015] Example 1: The device consists of vibrating screen 1, spring 2, fixed bottom plate 3, piston cylinder 4, piston rod 5, piston 6, bypass solenoid valve 7, damping solenoid valve 8, first absorber 9, and second absorber 10 composition, a spring 2 is connected between the vibrating screen 1 and the fixed bottom plate 3, the vibrating screen 1 is connected to the piston rod 5, the other end of the piston rod 5 is connected to the piston 6, the piston 6 is in dynamic fit with the inner cavity of the piston cylinder 4, the piston The cylinder 4 is connected to the fixed bottom plate 3. The piston cylinder 4 has a rod cavity oil port 4a and a rodless cavity oil port 4b. A bypass solenoid is connected between the rod cavity oil port 4a and the rodless cavity oil port 4b. Valve 7, a rod cavity oil port 4a is connected to the damping electromagnetic induction valve 8. The damping solenoid valve 8 is connected to one end of the first absorber 9 and the second absorber 10 in parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com