Straight plate type electromagnetic inner-curing equipment

An internal curing and electromagnetic technology, applied in induction heating, induction heating devices, etc., can solve the problems of high energy consumption, inability to guarantee product quality, and large heat dissipation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

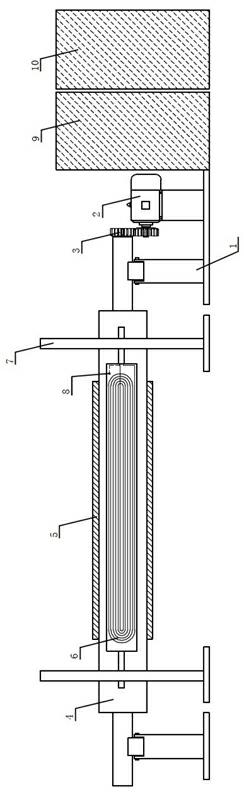

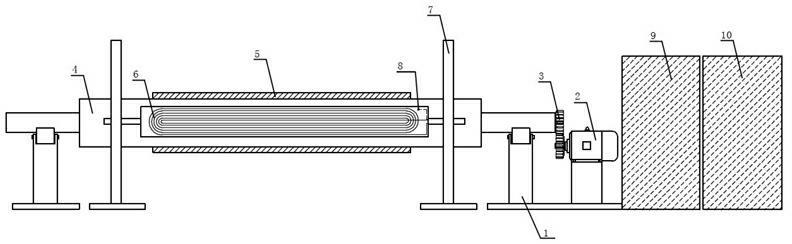

[0011] Below in conjunction with accompanying drawing, the present invention will be further described:

[0012] Straight plate type electromagnetic internal curing equipment, including a power controller 9, a system control cabinet 10, a motor 2, a mandrel bracket with rollers 1 and a coil support frame 7, and the mandrel bracket 1 with rollers is equipped with a magnetically conductive metal Mandrel 4, a fiber-reinforced plastic layer 5 is set outside the metal mandrel 4, one end of the metal mandrel 4 meshes with the gear on the motor 2 through the transmission gear 3, driven by the motor 2, the fiber reinforcement on the surface of the metal mandrel 4 The plastic layer 5 rotates at a constant speed; the coil 6 is arranged on the coil supporting frame 7, and the coil supporting frame 7 is arranged on either side of the mandrel bracket 1 with rollers, that is, the coil 6 is located on one side of the metal mandrel 4 instead of surrounding it. Around the metal mandrel 4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com