Multi-gear planet type hydraulic transmission driving mechanism

A technology of hydraulic transmission and transmission mechanism, which is applied in the direction of transmission box, transmission device, fluid transmission device, etc., and can solve problems such as poor fuel economy, difficult fuel consumption, and inability to meet the operation requirements of field operation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

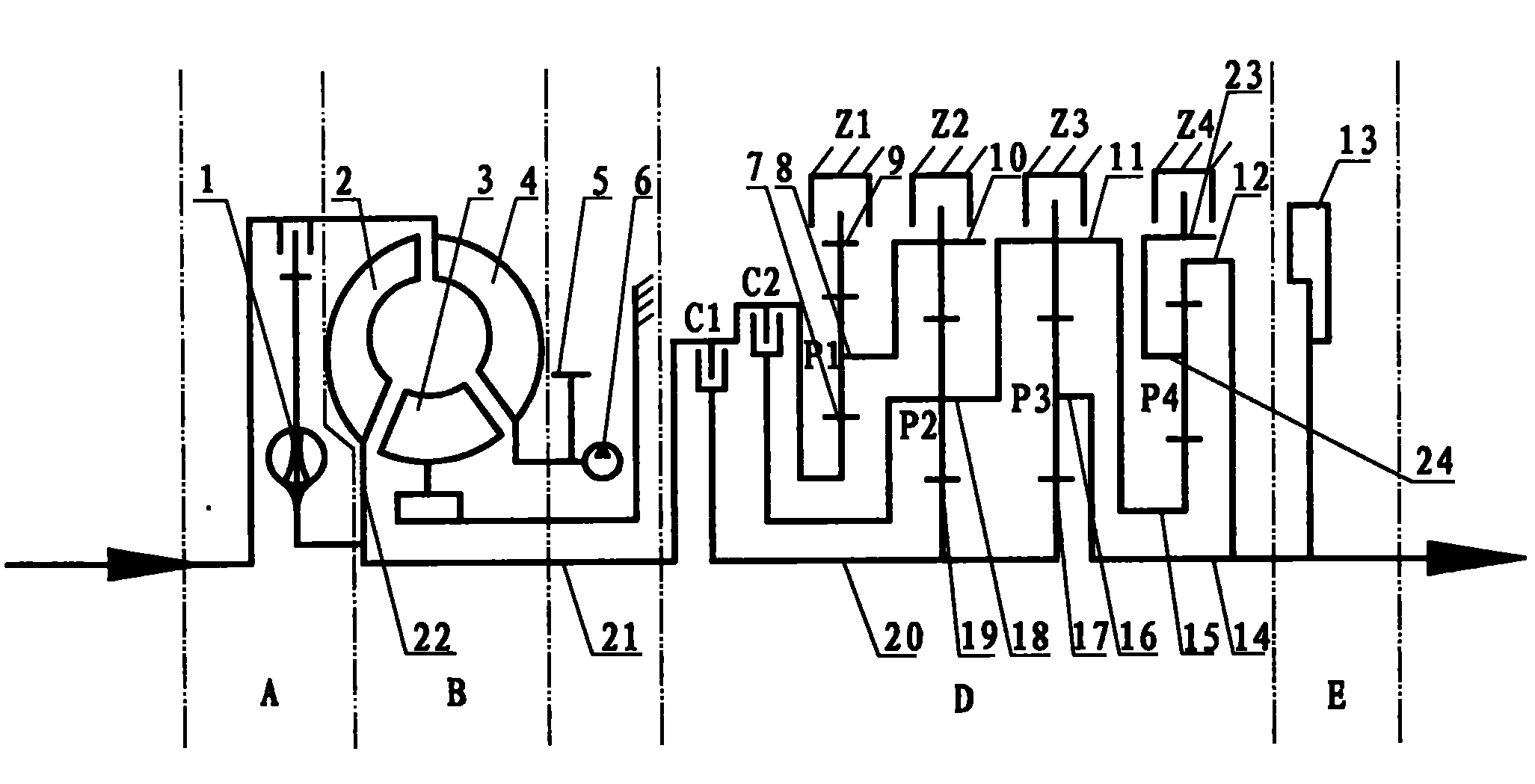

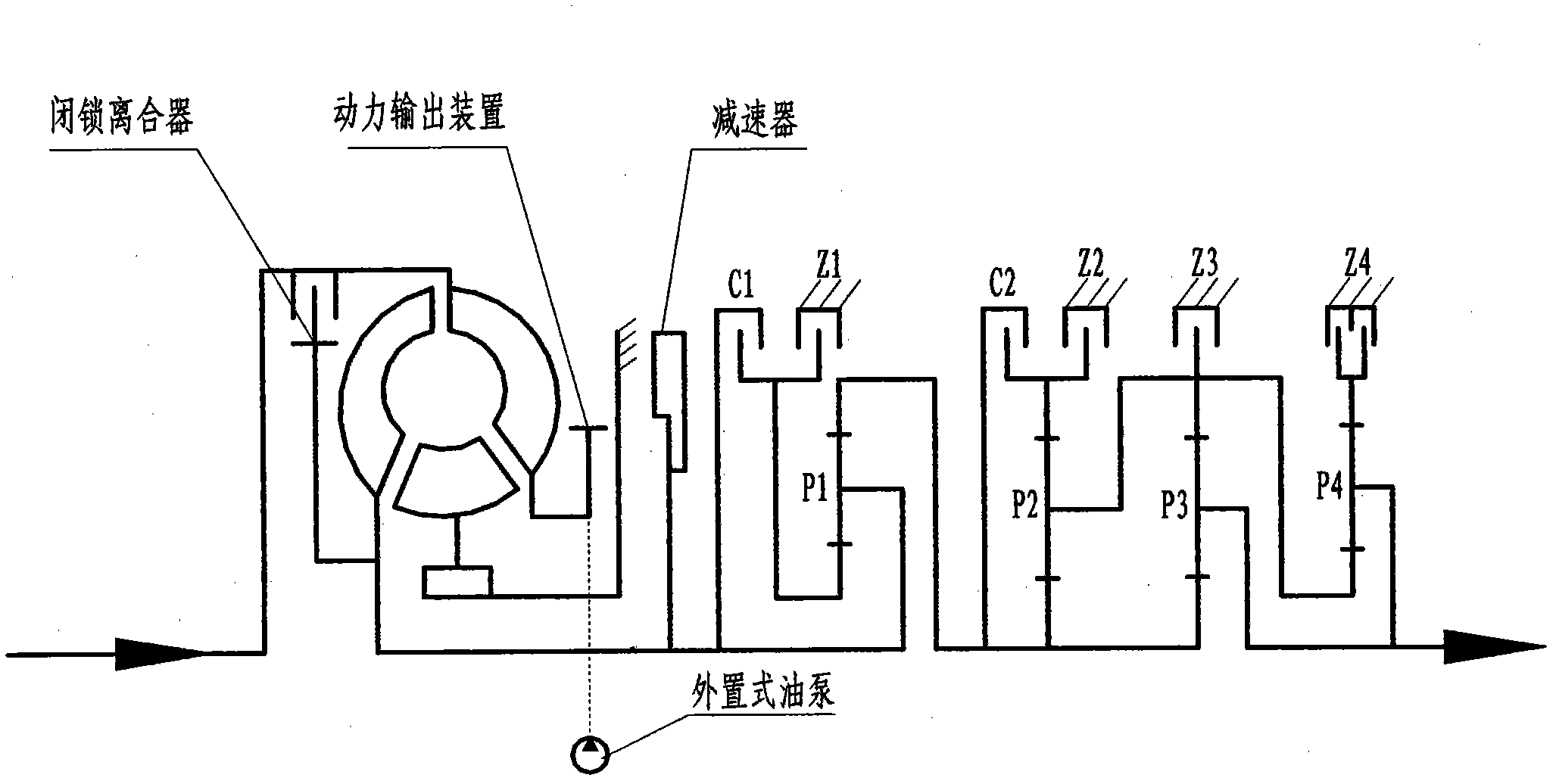

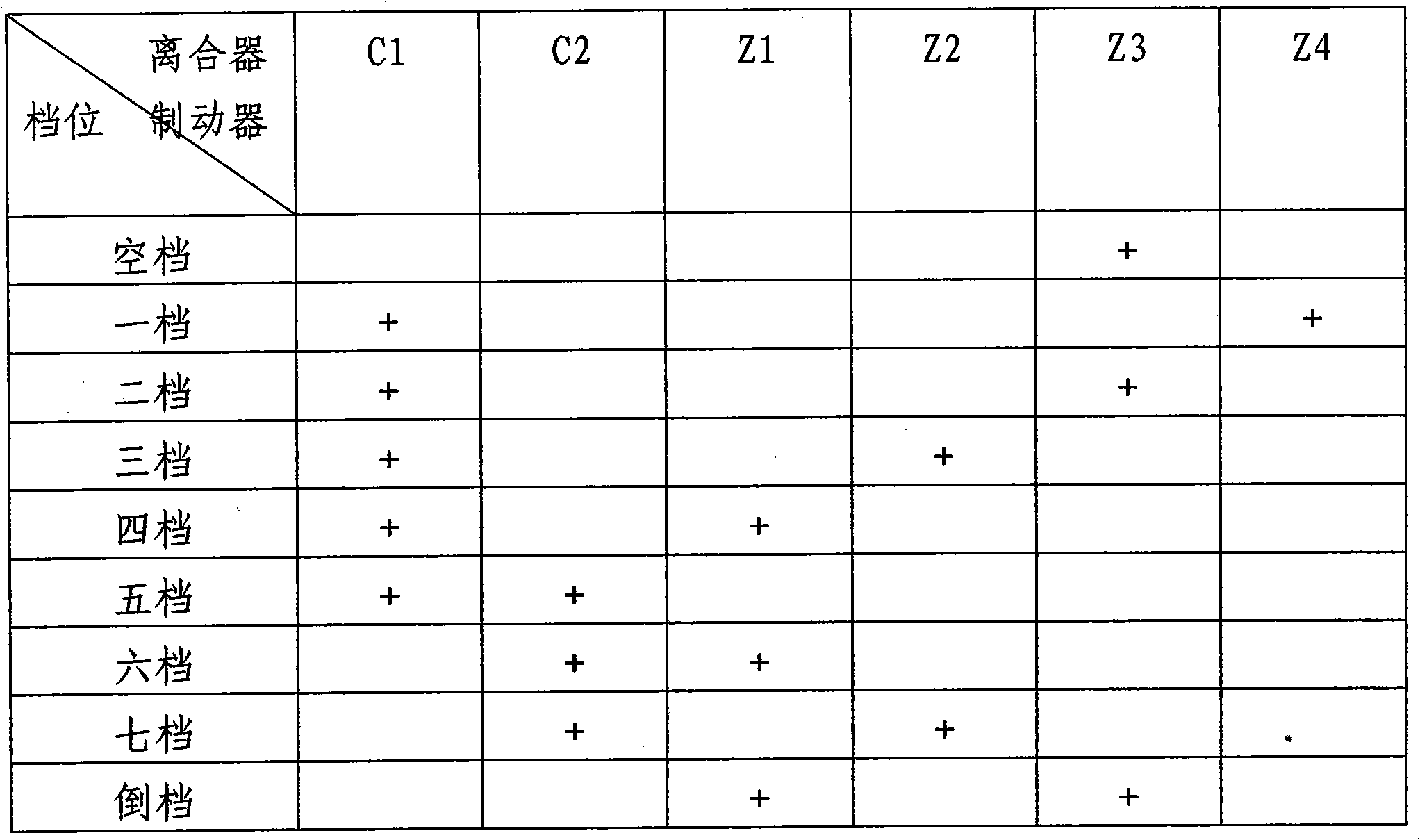

[0014] The pump wheel (4) is connected with the engine. When the engine speed is low, the hydraulic torque converter (B) is in the torque conversion condition, and the output power of the engine is absorbed by the torque converter turbine (2) after being acted on by the transmission oil. Afterwards, it is output by the turbine output shaft (21); when the engine speed is high, the hydraulic torque converter (B) is in the lock-up condition, and the lock-up and damping clutch piston is connected with the turbine seat (22) under the action of pressure oil, The engine and the turbine (2) form a rigid connection, the power provided by the engine is directly transmitted to the turbine output shaft (21) through the turbine seat (22), and the engine and the turbine output shaft (21) realize synchronous rotation, thereby improving the hydraulic transmission at high speed. The efficiency under the speed state widens the effective range. The turbine output shaft (21) is connected with the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap