High-altitude simulation testing system for piston engine

A technology of high-altitude simulation and test system, applied in the field of environmental simulation, can solve problems such as high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

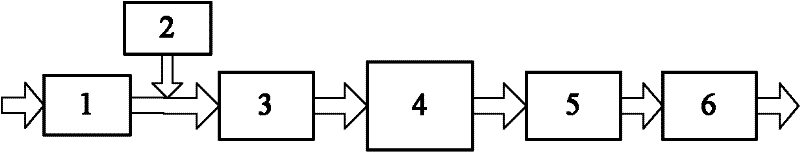

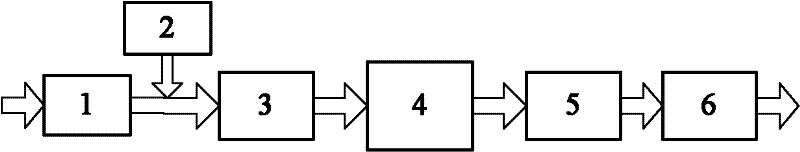

[0030] According to the present invention as figure 1 The piston engine high-altitude simulation test system of the embodiment of the present invention shown comprises: engine test bench 4, engine intake air temperature control system 1, engine intake air humidification system 2, engine intake air pressure control system 3, engine exhaust cooling device 5. Engine exhaust vacuum system 6, and other valves, pipe fittings, connectors, sensors, etc. (parts not shown).

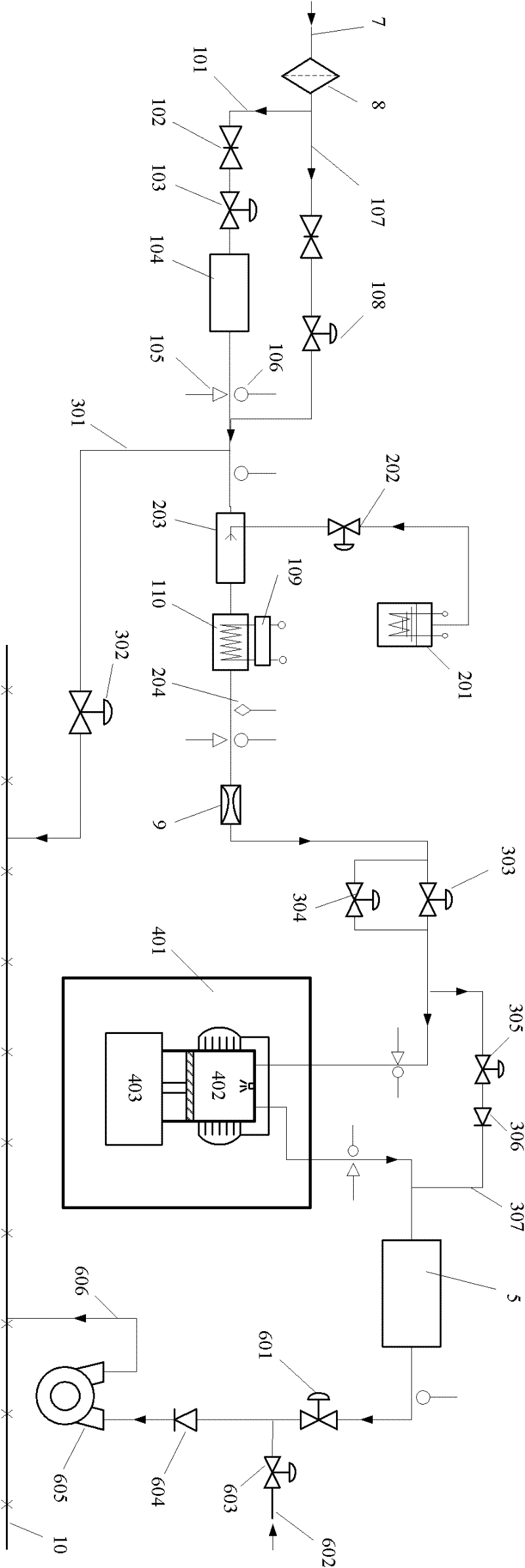

[0031] Such as figure 2 As shown, in the engine air intake temperature control system 1, the temperature control of the engine air intake is fast and accurate through the mixing of the air cooling circuit 101 and the air cooling bypass 107 and the electric heater 110 and its power regulator 109 Regulates engine intake air temperature. According to a specific embodiment of the present invention, in the engine air intake temperature control system 1, clean and dry compressed air (0.8-1.0Mpa) from an air source (no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com