Flat type SOFC (Solid Oxide Fuel Cell) monocell partial performance test device

A single-battery, flat-plate technology, applied in the direction of measuring devices, electric devices, and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve the problems of insufficient gas supply, differences in electrochemical performance, and uneven temperature distribution on the surface of batteries. Uniformity and other issues, to achieve accurate evaluation, the effect of uniform gas flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

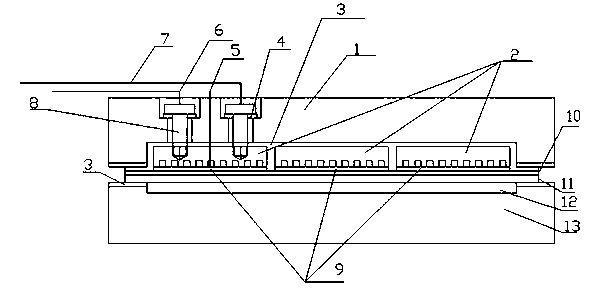

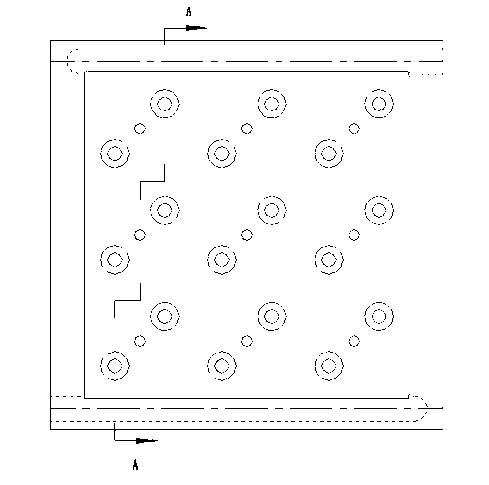

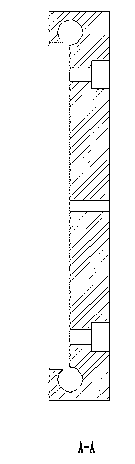

[0019] The following combination figure 1 ~ 4 further elaborates on the preferred embodiments of the present invention.

[0020] The present invention divides the traditional monolithic cathode current collector into multiple units, each unit has its own gas distribution channel, and each block unit is separated from the base of the current collector by an insulating material to communicate with the current collector. The current collector base is fixed on the current collector base with screws (conductive connectors) treated with insulation. The space between the adjacent sub-block current collecting units is kept, and a 3mm diameter through hole is opened in the middle of each unit, which is used to install thermocouples to collect the temperature of each partition of the battery. A threaded blind hole is processed on both sides of the through hole, which is used to install screws. On the one hand, the screws can connect each unit with the current collector base. On the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com