Nondestructive quick file photographing instrument

A non-destructive, camera-based technology, applied in TV, color TV parts, electrical components, etc., can solve the problems of large damage to processing objects, difficult batch processing by computers, cumbersome workflow, etc., to solve the problem of uneven exposure and Accurate, avoid external light source interference, simplify the effect of the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

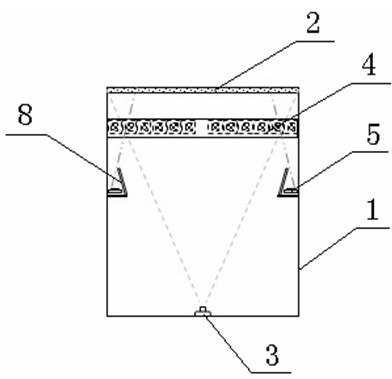

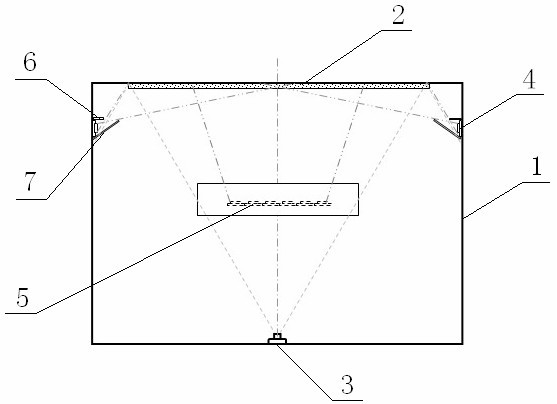

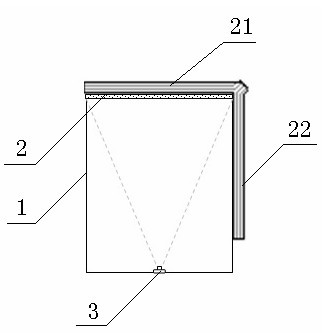

[0027] Such as figure 1 , 2 As shown, the non-damaging quick document camera of the present embodiment includes a box body 1, and the top surface of the box body 1 is provided with a rectangular glass panel 2 used as a document bracket, and its two long sides are used as "double zero margins". ”, the bottom surface of the box body 1 is equipped with an image sensor 3 facing the glass panel 2, the field of view of the image sensor 3 is in the long direction, and its two long sides coincide with the two long sides of the glass panel 2; There are multiple directional light sources pointing to different positions, so that the brightness at the central position of the glass panel 2 has a decreasing trend compared with the brightness at the edge positions, and the directional light sources are installed outside the field of view of the image sensor 3 .

[0028] The above-mentioned directional light source includes a main light source 4 and an auxiliary light source 5. There are two...

Embodiment 2

[0037] Such as Figure 5 , 6 As shown, the non-damaging quick document camera of this embodiment includes a box body 9, and the top surface of the box body 9 is provided with two rectangular glass panels 10 used as document holders, and the long sides of the two glass panels 10 are offset to form an inverted V-shaped structure, the angle between the two glass panels 10 is 90°, two image sensors 11 are fixed on the bottom of the box body 9, and each image sensor 11 is perpendicular to the center of the glass panel 10 on its far side.

[0038] The directional light source includes a main light source 12, a first auxiliary light source 13 and a second auxiliary light source 14, wherein:

[0039] There are two main light sources 12, and they are respectively fixed on the inner side of the two image sensors 11, that is, the underside of the long side of the glass panel 10, and the direction is parallel to the long side of the glass panel 10, and are composed of two groups of LED l...

Embodiment 3

[0044] Such as Figure 7 As shown, the non-damaging quick document camera of this embodiment is basically the same as that of Embodiment 2, and an image sensor 11, a main light source 12, a first auxiliary light source 13 and a second auxiliary light source 14 are arranged inside it, and the inside and outside of the main light source 12 are Light baffles 15, 16 are arranged on both sides, and light baffles 17 are arranged on both sides of the first auxiliary light source 13; the difference between the two is that the box body 9 in this embodiment is inverted, and the two rectangular glass panels 10 are arranged on the sides of the box body 9. On the bottom surface, where the long edges of the two glass panels 10 meet, a groove 18 for accommodating the spine of the photographed book is provided, and one side of the box body 9 is open for taking and placing the photographed book.

[0045] In order to ensure that the photographed page is in a flat state, it is better to add a "V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com