Rotary fluid machine

A fluid machinery, rotary technology, applied in the direction of rotary piston machinery, mechanical equipment, rotary piston pump, etc., can solve problems such as efficiency reduction, heat exchange obstacles, reliability reduction, etc., to ensure reliability and expand space volume. , to achieve the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

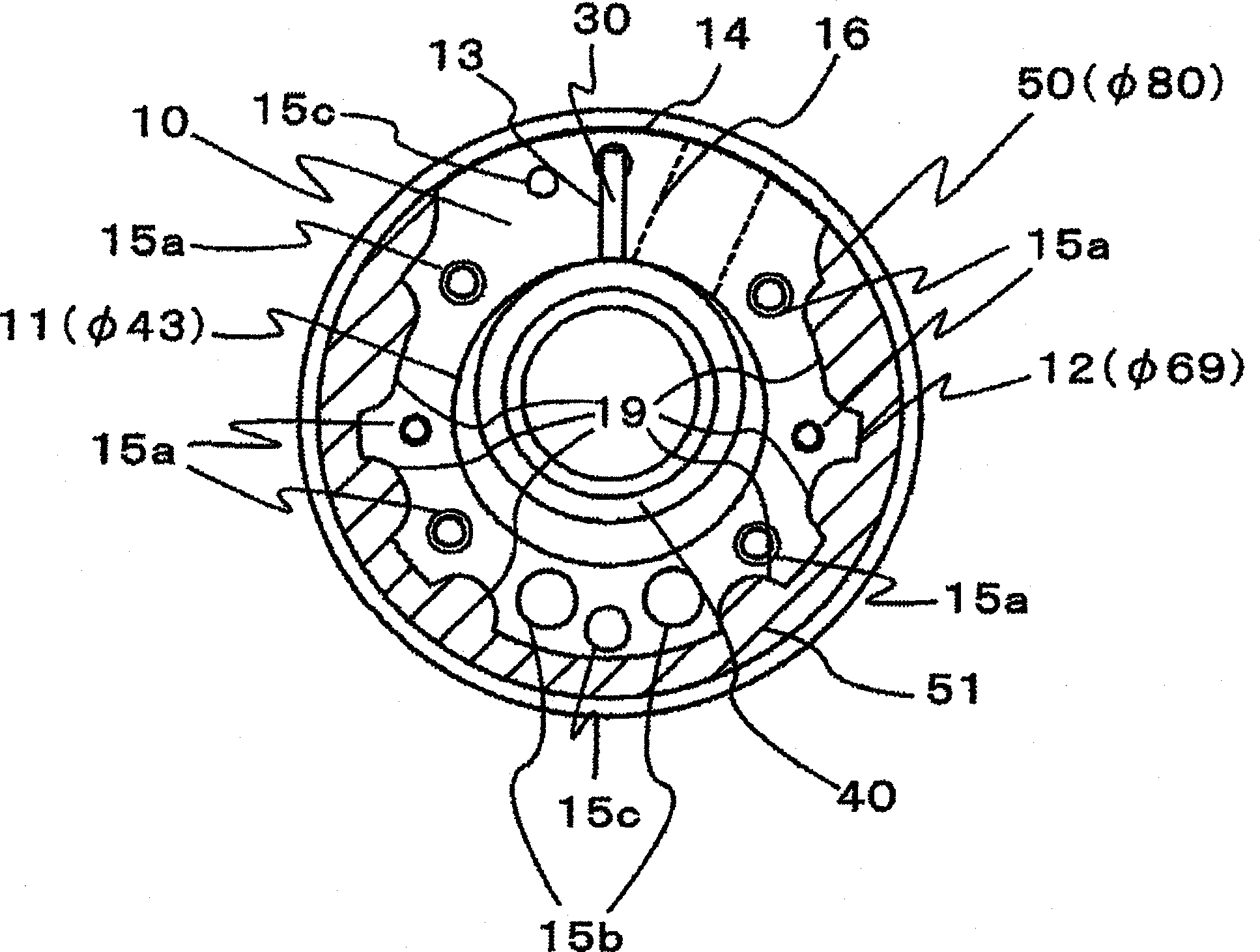

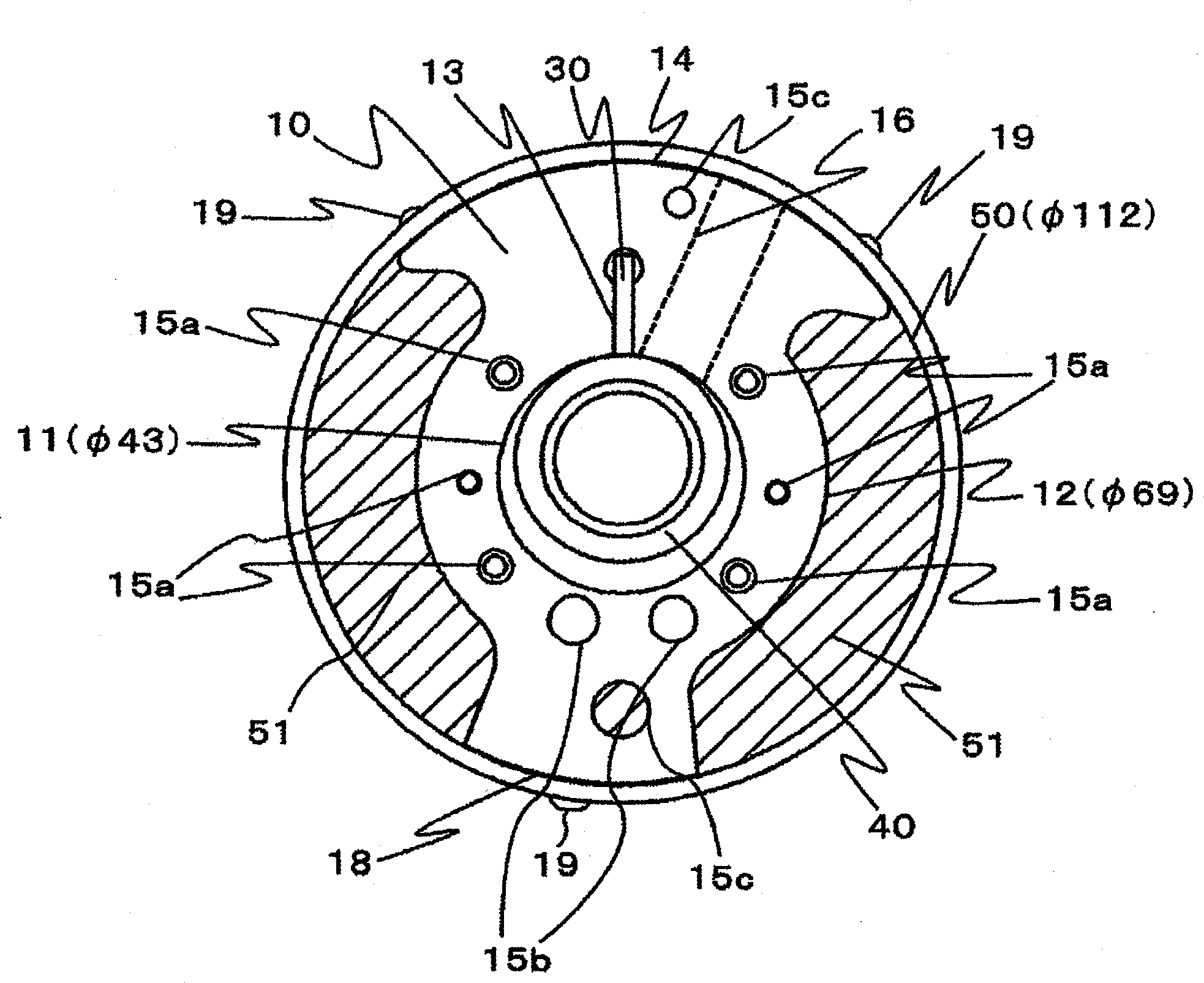

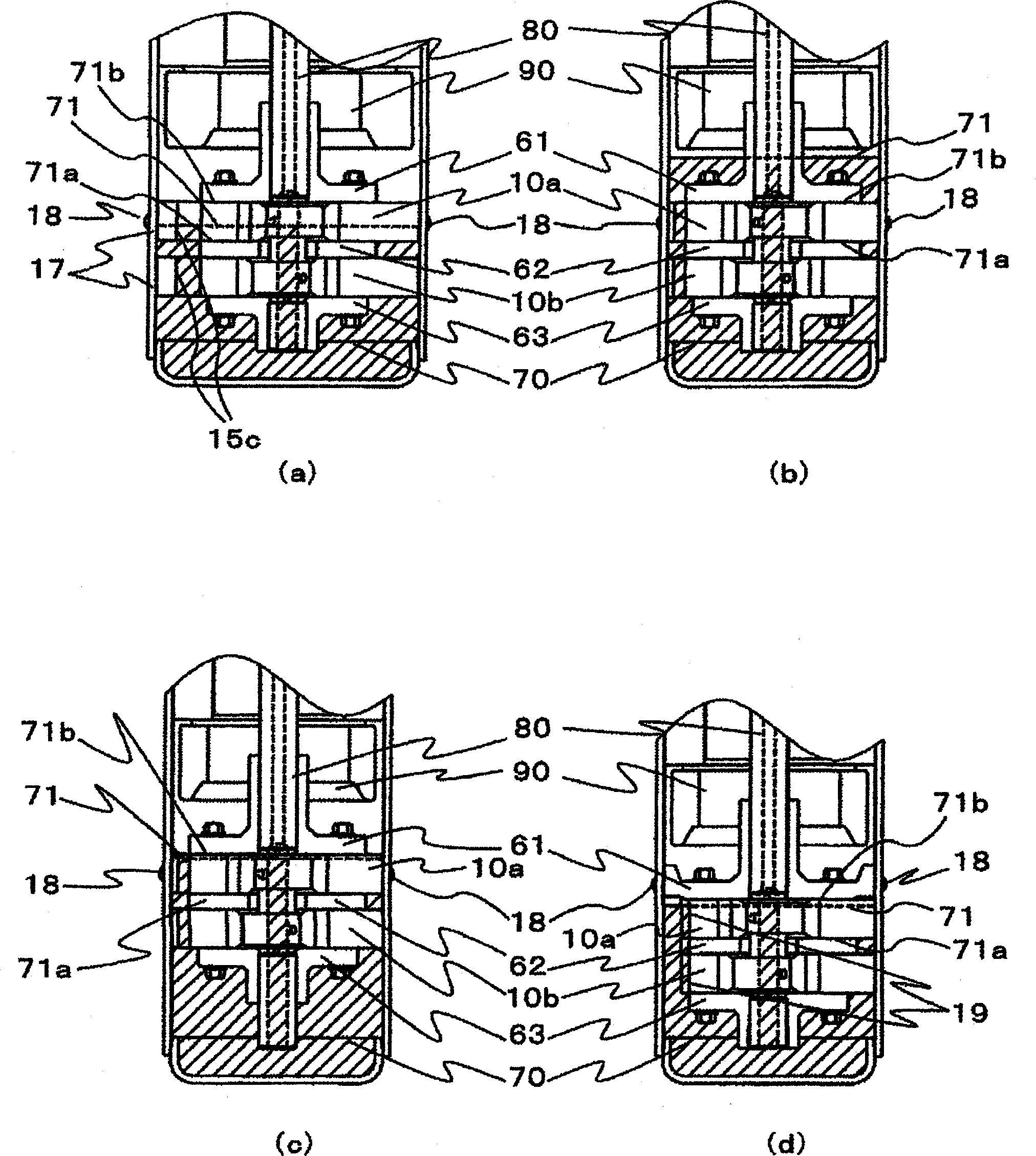

[0019] As an embodiment of the present invention, a rotary compressor for an air conditioner having the following configuration will be described as an example. The electric motor part is accommodated in the airtight container, and a crankshaft having an eccentric part for transmitting the rotation of the electric motor part, a compression mechanism part driven by the eccentric part, and a blocking member for blocking the compression mechanism part along the direction of the crankshaft are provided, so The compression mechanism part includes: a working cylinder; a roller arranged in the working cylinder and rotationally driven by the eccentric part of the crankshaft; a vane that moves in and out of the storage portion of the cylinder; and a spring that presses the vane against a roller. The compression mechanism unit is accommodated below the motor unit in the airtight container. The closing member has a bearing for holding the crankshaft, and is composed of an upper bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com