Glass container fire polishing machine

A technology of flame polishing and glass containers, which is applied in the field of glass processing, can solve problems such as unresolved, and achieve the effects of fast speed, high heat treatment temperature and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

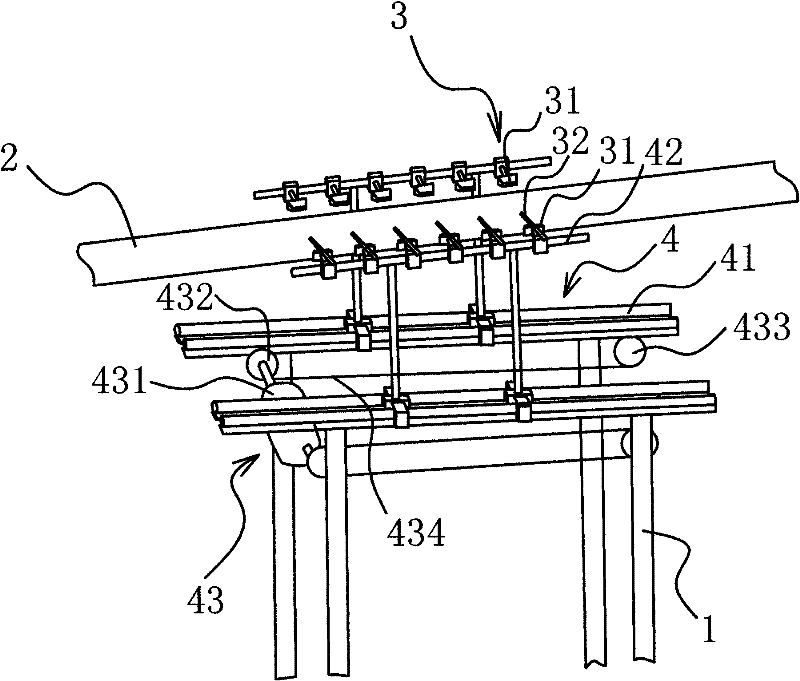

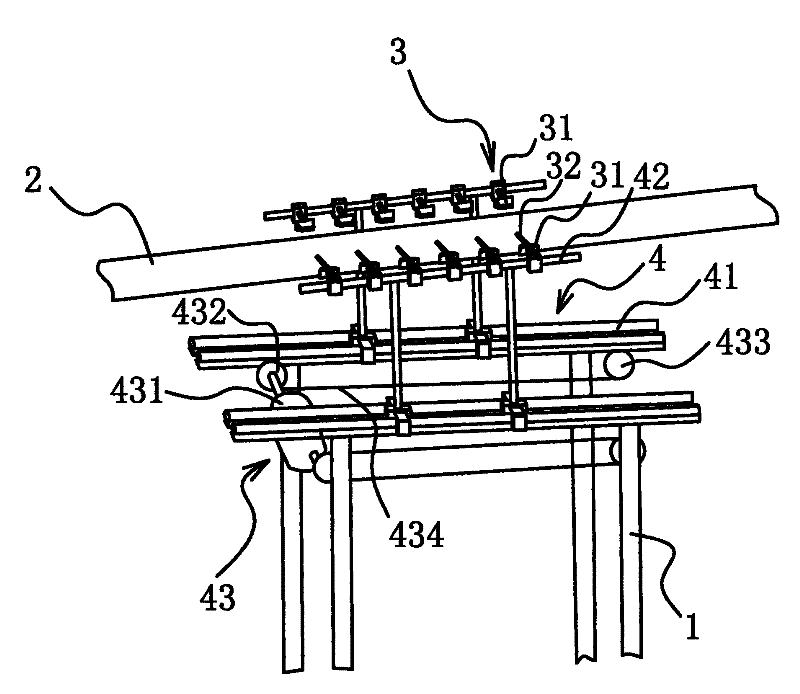

[0014] Such as figure 1 As shown, the flame polishing machine for glass containers includes a frame 1, and a conveyor belt 2 for transporting glass containers is arranged above the frame 1. Several groups of flame polishing mechanisms 3 are arranged on the frame 1 , and each flame polishing mechanism 3 is arranged in sequence along the conveyor belt 2 . The flame polishing mechanism 3 is respectively connected with the liquid oxygen supply source and the propane supply source.

[0015] In this embodiment, the number of flame polishing mechanisms 3 is six groups. Each flame polishing mechanism 3 is connected with the frame 1 through an adjustable movable mechanism 4, and the adjustable movable mechanism 4 can drive each flame polishing mechanism 3 to move along the conveyor belt 2 and when each flame polishing mechanism 3 moves along the conveyor belt 2 The lifting and lowering of each flame polishing mechanism 3 in the vertical direction can be realized at the same time.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com