Wire insulation cap

A technology of wire insulation and insulation cap, which is applied in the field of safety protection devices, can solve the problems of inconvenient wrapping of cable ends, and achieve the effects of high work efficiency, pollution reduction and safety improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

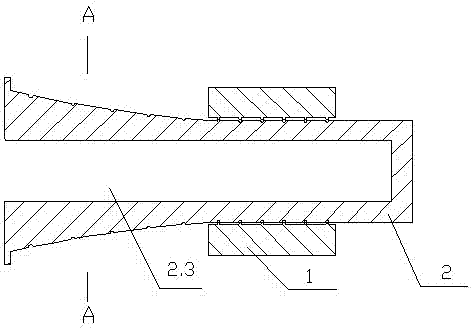

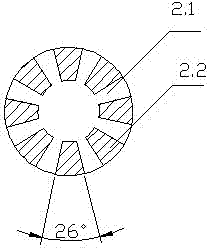

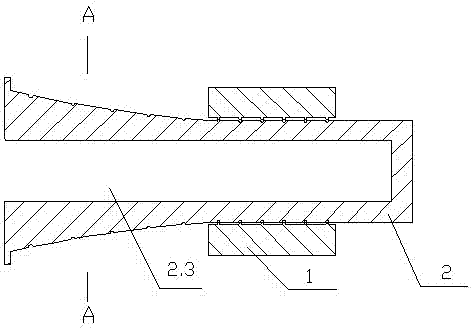

[0011] An insulating cap for wires, which includes a trumpet-shaped insulating cap 2 made of rubber and a nut 1 installed outside the insulating cap 2. Threads matching the nut 1 are processed on the outer surface of the insulating cap. Nut 1 is made of metal, hard plastic or hard rubber, and it is non-deformable. The left side of the insulating cap 2 is conical, and the right side is cylindrical. A blind hole 2.3 is provided in the frustum-shaped insulating cap 2 at the bell mouth end. Around the blind hole, that is, the frustum-shaped insulation cap, cut out some longitudinal gaps 2.1, so that this part forms several claws 2.2 whose cross-section is fan-shaped, and the fan-shaped central angle of the claw 2.2 is 26 degrees. During use, the cable ends are inserted in the blind hole 2.3 of the insulating cap 2, and when the nut 1 is rotated forward, several claws 2.2 at the front end of the insulating cap 2 are tightened and closed, and the cable ends are wrapped therein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com