A steam injection boiler high temperature separation water reuse treatment system and treatment method

A technology of steam injection boiler and treatment system, applied in the field of high temperature separation water reuse treatment system of steam injection boiler, can solve the problems of large amount of cooling water, poor economy, blockage of traditional membrane process, etc., to reduce heat loss, ensure quality requirements, The effect of ensuring water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

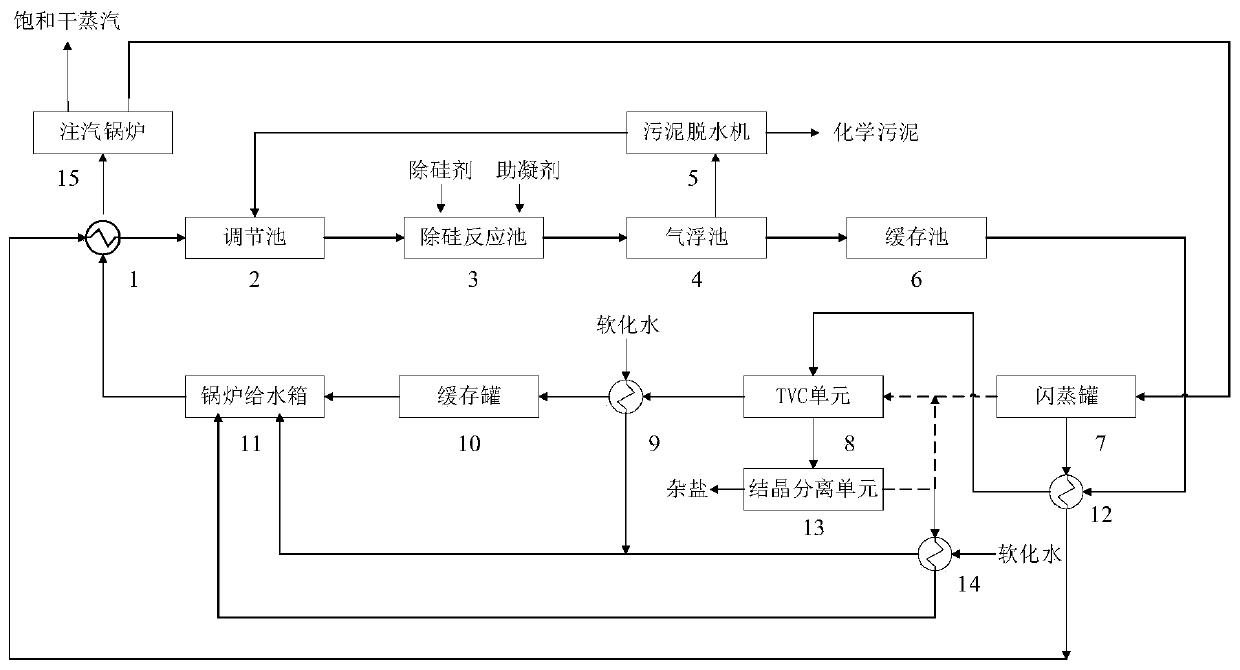

[0060] 1) The high-temperature separated water produced by the steam injection boiler enters the flash tank; the high-temperature separated water of the steam injection boiler produces secondary steam at a temperature of about 140°C in the flash tank, and at the same time produces part of the flash condensate with a temperature of about 140°C. The flash condensate produced by the steamer is about 60% of the high temperature separated water;

[0061] 2) The secondary steam generated by the flash tank is used as the ejection steam of the TVC unit, and enters the TVC unit together with the secondary steam generated by the crystallization separation unit;

[0062] 3) The flash condensate passes through the first heat exchanger 12 and the second heat exchanger 1 to exchange heat with the silicon removal wastewater and boiler feed water, and then enters the regulating pool at a temperature of about 80°C, and adjusts the pH in the regulating pool to 7~10;

[0063] 4) The adjustment t...

Embodiment 2

[0070] 1) The high-temperature separated water produced by the steam injection boiler enters the flash tank; the high-temperature separated water of the steam injection boiler produces secondary steam at a temperature of about 160°C in the flash tank, and at the same time produces part of the flash condensate with a temperature of about 160°C. The flash condensate produced by the steamer is about 50% of the high temperature separated water;

[0071]2) The secondary steam generated by the flash tank is used as the ejection steam of the TVC unit, and enters the TVC unit together with the secondary steam generated by the crystallization separation unit;

[0072] 3) The flash condensate passes through the first heat exchanger 12 and the second heat exchanger 1 to exchange heat with the silicon removal wastewater and boiler feed water, and then enters the regulating tank at a temperature of about 65°C, and adjusts the pH in the regulating tank to 7~10;

[0073] 4) The adjustment ta...

Embodiment 3

[0080] 1) The high-temperature separated water produced by the steam injection boiler enters the flash tank; the high-temperature separated water of the steam injection boiler produces secondary steam at a temperature of about 160°C in the flash tank, and at the same time produces part of the flash condensate with a temperature of about 160°C. The flash condensate produced by the steamer is about 50% of the high temperature separated water;

[0081] 2) The secondary steam generated by the flash tank is used as the ejection steam of the TVC unit, and enters the TVC unit together with the secondary steam generated by the crystallization separation unit;

[0082] 3) The flash condensate passes through the first heat exchanger 12 and the second heat exchanger 1 to exchange heat with the silicon removal wastewater and boiler feed water, and then enters the regulating tank at a temperature of about 65°C, and adjusts the pH in the regulating tank to 7~10;

[0083] 4) The adjustment t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com