Method for manufacturing superplastic forming and diffuse bonding magnesium alloy product

A technology of superplastic forming and diffusion bonding, which is applied in the direction of manufacturing tools, welding equipment, hollow objects, etc., and can solve the problems of poor forming performance and restricting the development of magnesium alloy sheet forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

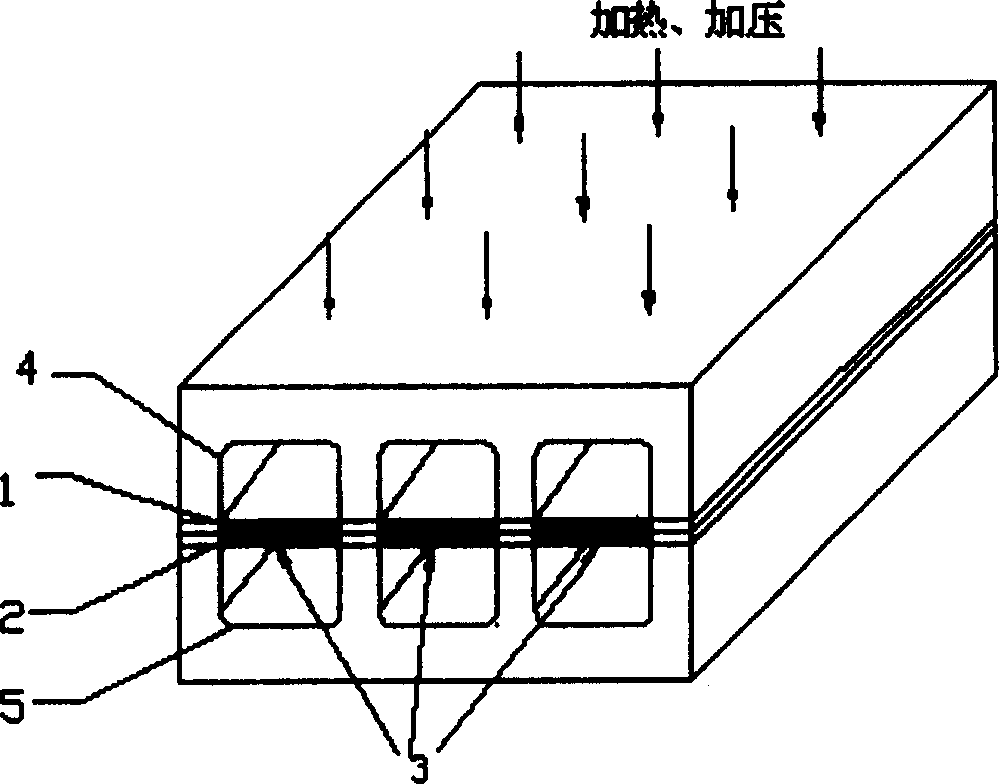

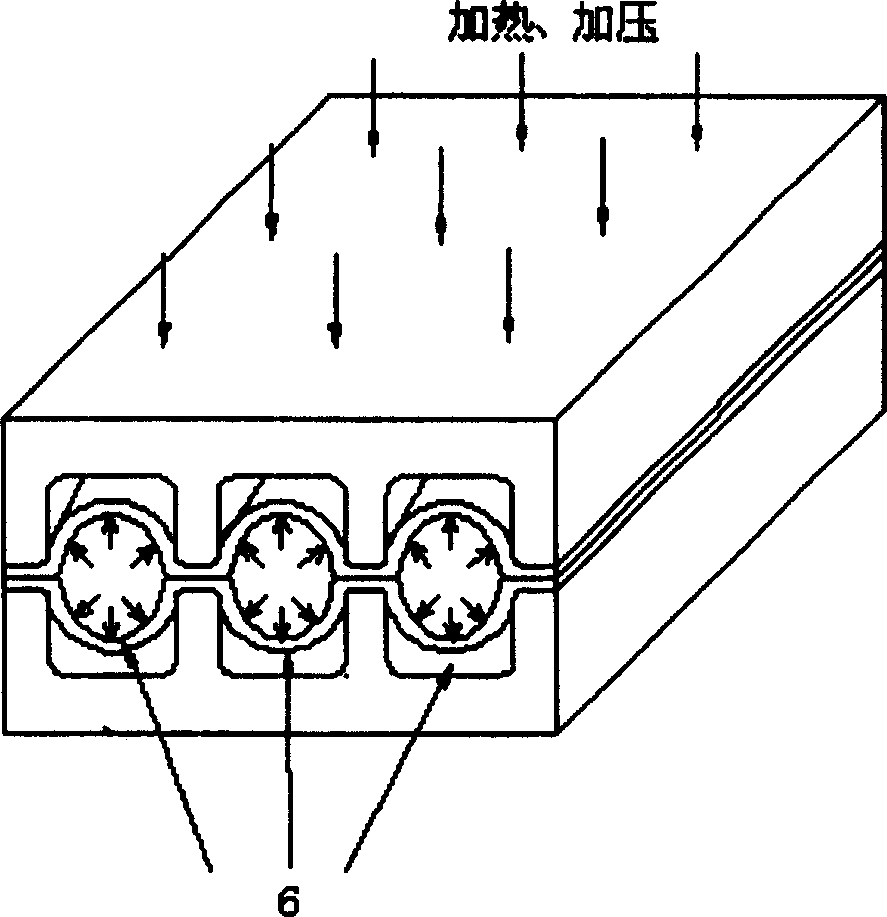

[0005] Specific Embodiment 1: This embodiment is to manufacture superplastic forming and diffusion-bonded magnesium alloy products in this way: a. Prepare plates: chemically clean the connecting surfaces of two or more magnesium alloy plates, and remove the surface of the plates. Oxide film to expose the fresh surface to increase the contact area and achieve better joint quality; b. Preparation of gasification agent: The gasification agent undergoes a chemical reaction near the superplastic temperature of the magnesium alloy, and the product is accompanied by a large amount of The gas, in the closed space, produces a very high internal pressure, using this air pressure for superplastic molding, the gasification agent is a solid substance, and the gasification agent is placed between the two plates; c, heating, Pressurization process: put the sheet material with gasifying agent into the mold, the mold is composed of upper mold 4 and lower mold 5, the upper mold 4 and lower mold ...

specific Embodiment approach 2

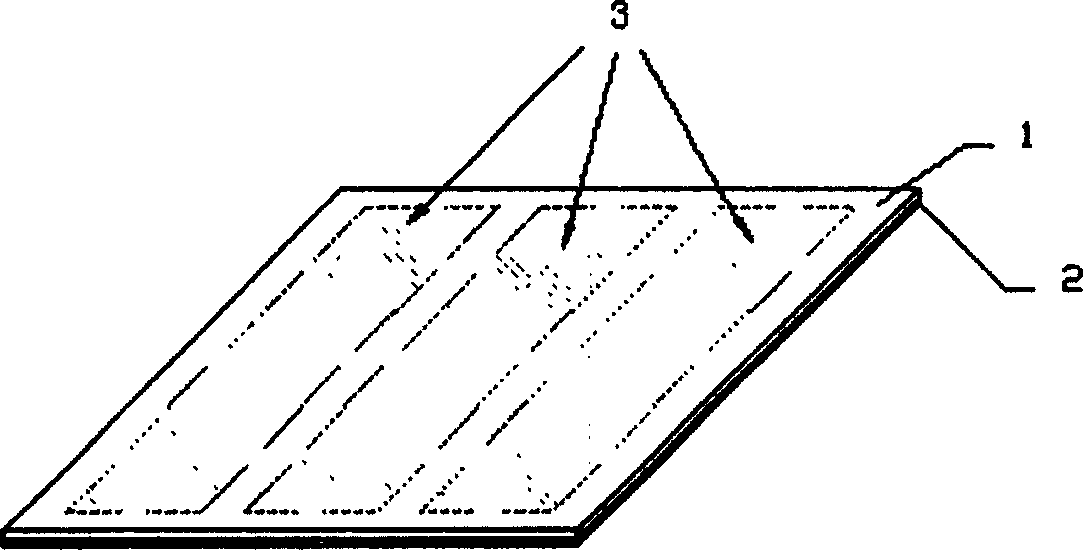

[0006] Specific embodiment 2: The sheet material of this embodiment adopts Mg-Zn-Zr thin plates 1 and 2 with a thickness of 1.2 mm. a. Chemically clean the connecting surface of the two plates to remove the oxide film and pollutants on the surface of the plates, such as oil, rust, dirt, etc., to expose the fresh surface to increase the contact area and form a firm connection between the joints; b , Place 3g of gasifying agent 3 on three positions between the two plates, such as figure 1 Shown; c, sheet material 1 and sheet material 2 that are clamped with gasification agent 3 are packed in upper die 4 and lower die 5, and the process of heating and pressing is carried out in the superplastic molding machine, as figure 2 As shown, the sheet is heated to the superplastic forming temperature of magnesium alloy at 350°C, and a pressure of 10 MPa is applied at the same time, so that the upper mold 4 and the lower mold 5 are in close contact with the sheet 1 and sheet 2 to form a c...

specific Embodiment approach 3

[0007] Specific embodiment three: The sheet material of this embodiment adopts Mg-Zn-Zr thin plates 1 and 2 with a thickness of 0.8 mm. a. Chemically clean the connecting surface of the two plates to remove the oxide film and pollutants on the surface of the plates, such as oil, rust, dirt, etc., to expose the fresh surface to increase the contact area and form a firm connection between the joints; b , Place 3g of gasifying agent 3 on three positions between the two plates, such as figure 1 Shown; c, the sheet material 1 and 2 that are clamped with gasification agent 3 are packed in die upper die 4 and lower die 5, and the heating and pressing process is to carry out in superplastic molding machine, as figure 2 As shown, the sheet is then heated to the superplastic forming temperature of magnesium alloy at 300°C, and a pressure of 10 MPa is applied at the same time, so that the upper mold 4, the lower mold 5 and the sheet are in close contact to form a closed space, as shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com