Centrifugal abrasive grain projectile device

A projection device and abrasive particle technology, applied in the direction of explosion generating device, abrasive material, metal processing equipment, etc., can solve the problems of time-consuming side liner, time-consuming replacement of impeller blades, huge weight of impeller, etc., and achieve the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

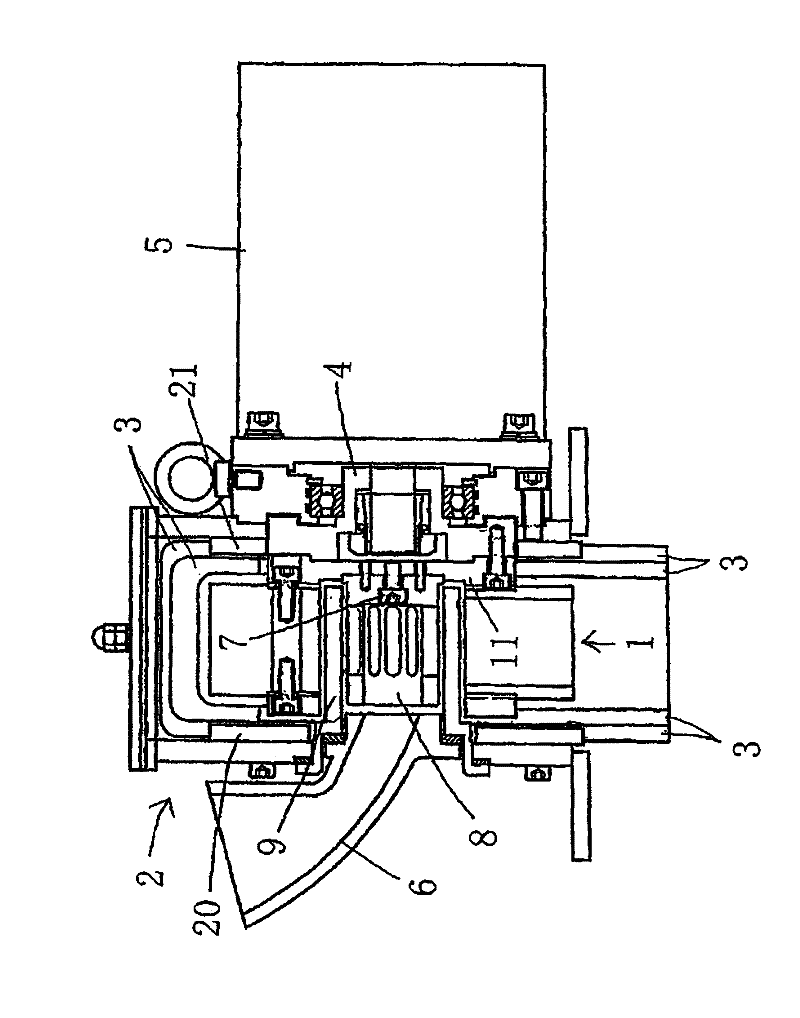

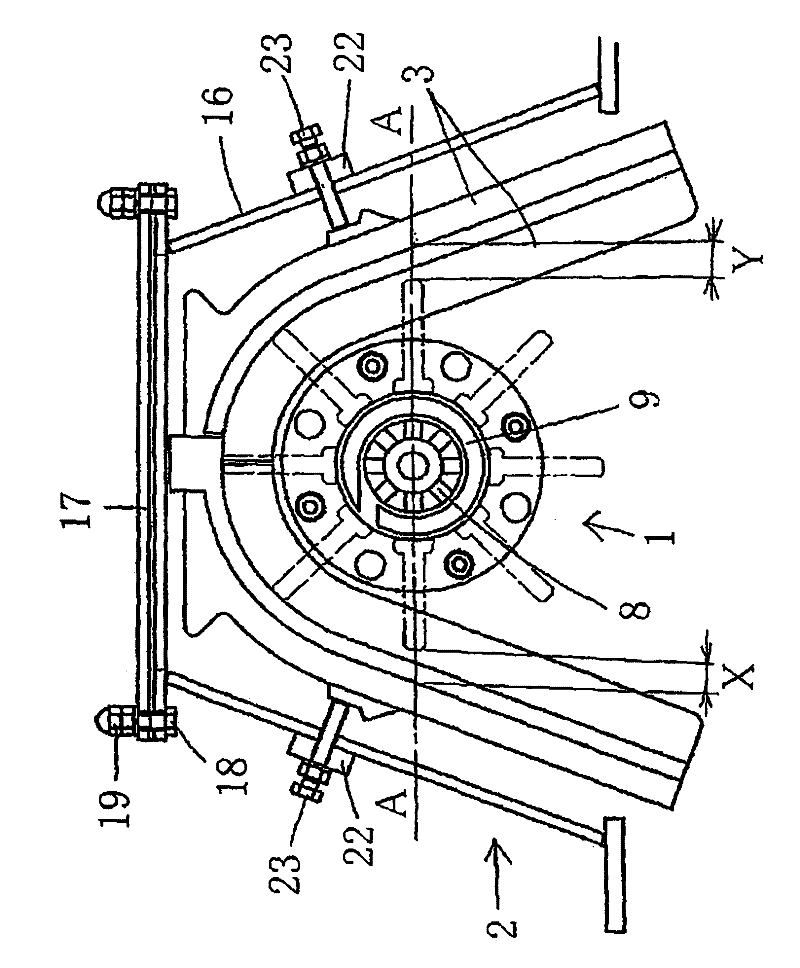

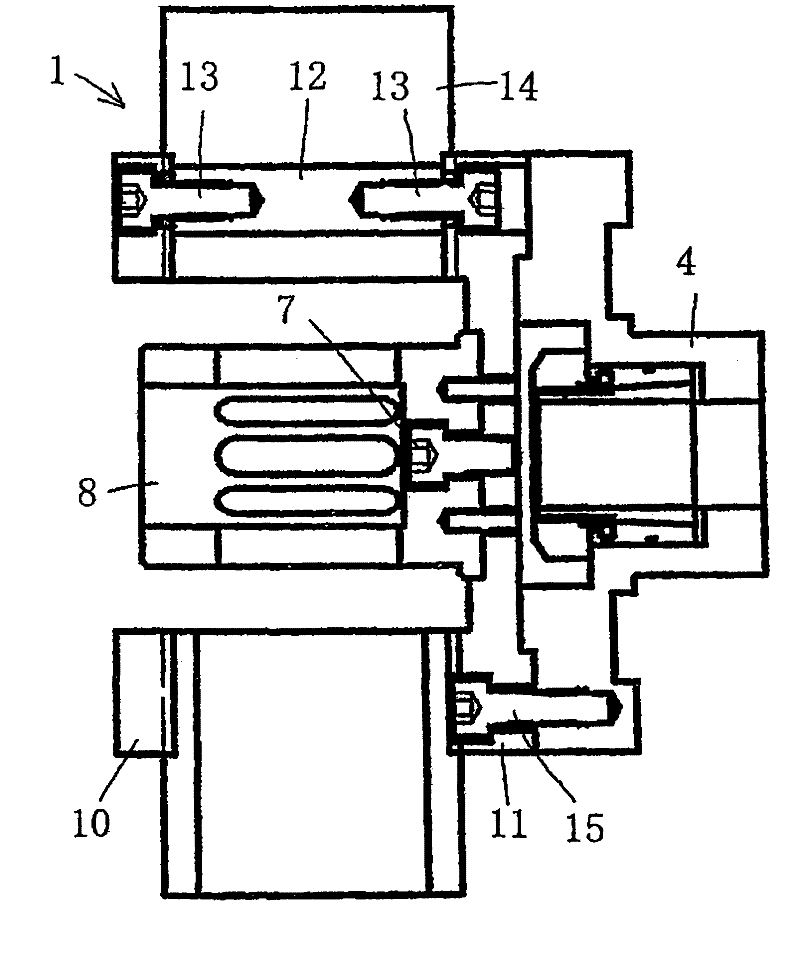

[0014] Below, combine Figure 1 ~ Figure 3 One embodiment of the abrasive centrifugal projection device to which the present invention is applied will be described in detail. Such as figure 1 as well as figure 2 As shown, the abrasive particle centrifugal projection device is composed of an impeller 1, an impeller cover 2, a side liner 3, a motor 5, a guide pipe 6, a distributor 8, and a control box 9, wherein the impeller 1 rotates and the abrasive particles are centrifugally projected , the impeller housing 2 surrounds the impeller 1 and prevents the scattering of abrasive grains to the outside, the side gasket 3 protects the side wall in the impeller housing 2 in the radial direction of the impeller 1 from the projection of abrasive grains, the motor 5 is fixedly arranged, and The impeller 1 is installed on the motor 5 via the hub 4 fitted to the output shaft of the motor; the guide pipe 6 is installed on the impeller housing 2 and guides the abrasive grains into the imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com