Movable trolley for light ship welding

A technology for moving trolleys and hulls, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of easy deformation of hull thin plate welding, and achieve the effect of improving work efficiency and controlling welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

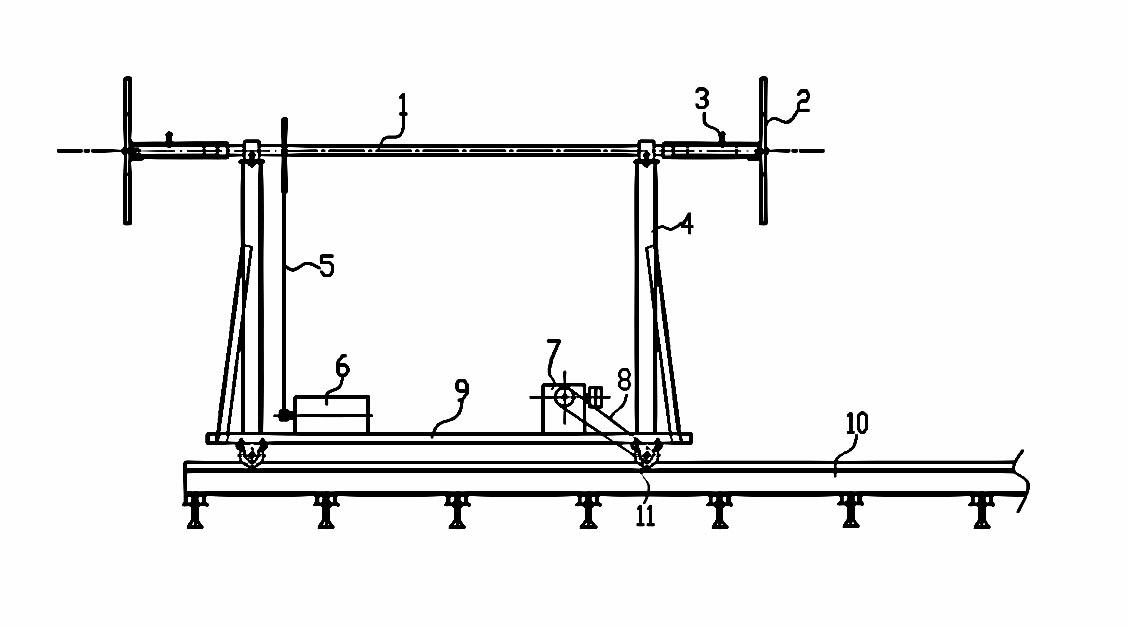

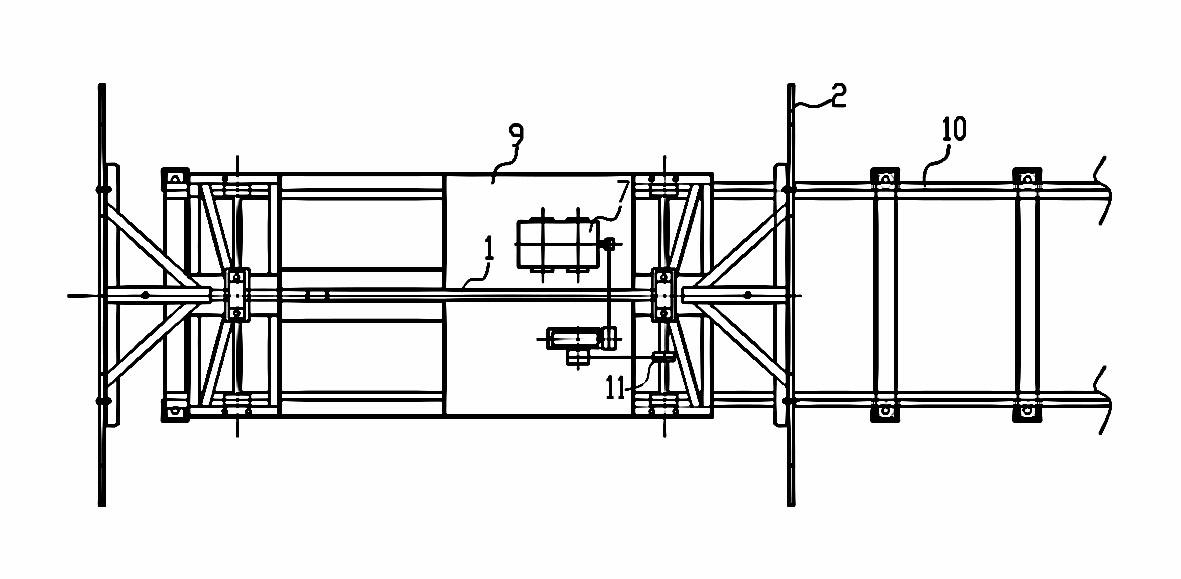

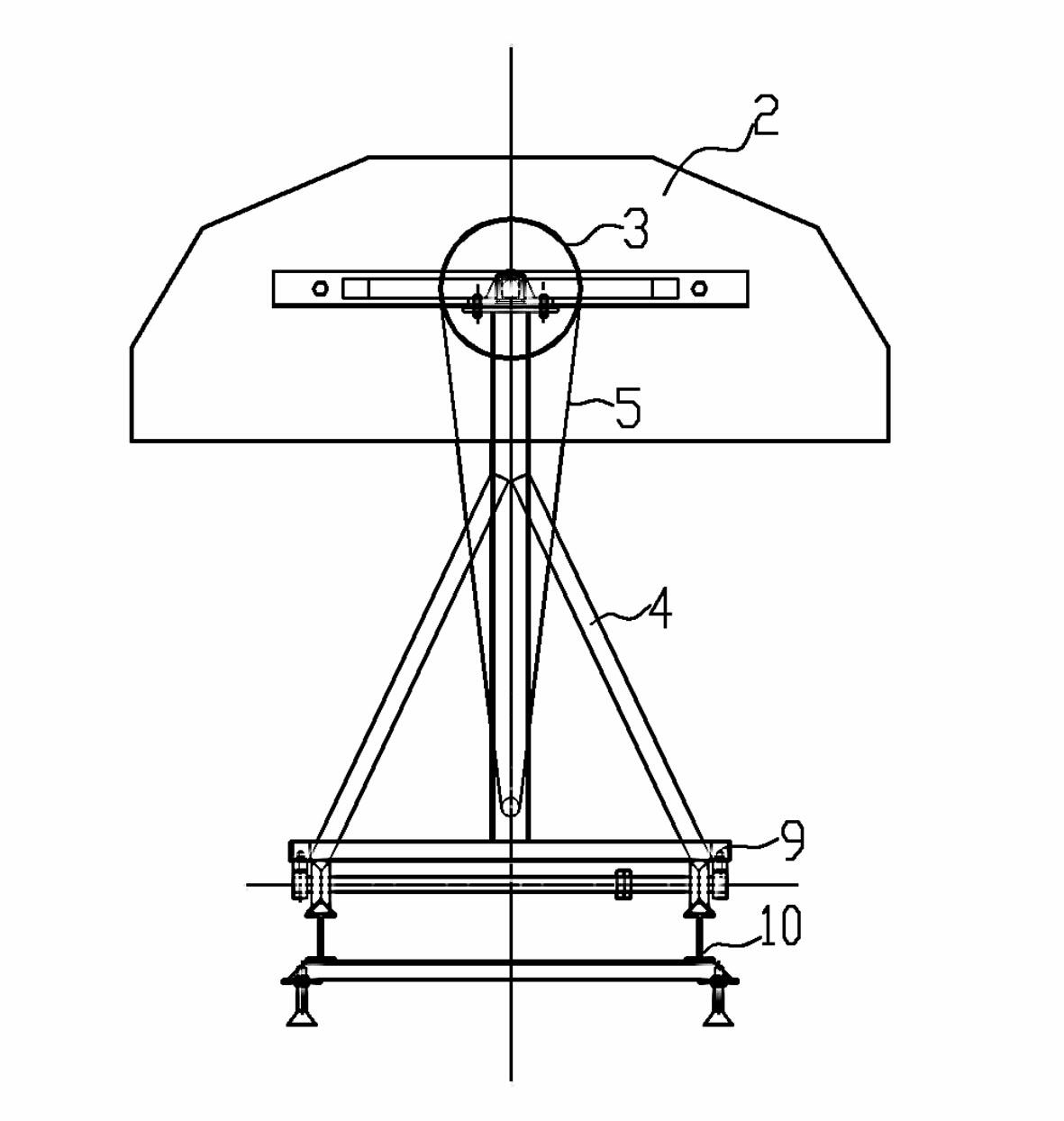

[0014] like figure 2 As shown, a mobile trolley used for light hull welding of the present invention includes a section of walking track 10 laid on the ground. The track 10 is formed by connecting two parallel I-beams through sleepers. A mobile trolley is provided, and the mobile trolley comprises a bottom plate 9, two longitudinally placed wheel axles 11 are arranged under the bottom plate 9, and a wheel is respectively arranged at both ends of the wheel axle 11, and the wheels of the mobile trolley cooperate with the track, and the bottom plate of the trolley 9 is provided with a drive device 7, the drive device is preferably selected from an electromagnetic speed regulator and a speed reducer, the drive device 7 is connected to one of the wheel shafts 11 through a transmission device 8, and the transmission device 8 is preferably selected from a chain The transmission mechanism can also be a belt transmission mechanism. A sprocket and a pulley are respectively arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com