Electrostatic film underseal bag making machine

A bag-making machine and electrostatic film technology, applied in the field of electrostatic film bottom-sealing bag-making machines, can solve problems such as low production efficiency, affecting the production quality of bottom-sealed packaging bags, and non-parallel and neat packaging bag films, so as to improve production quality and The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

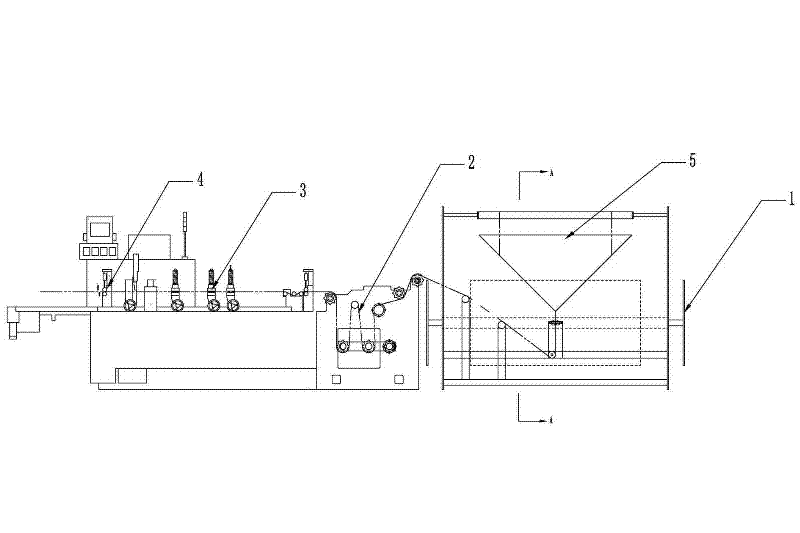

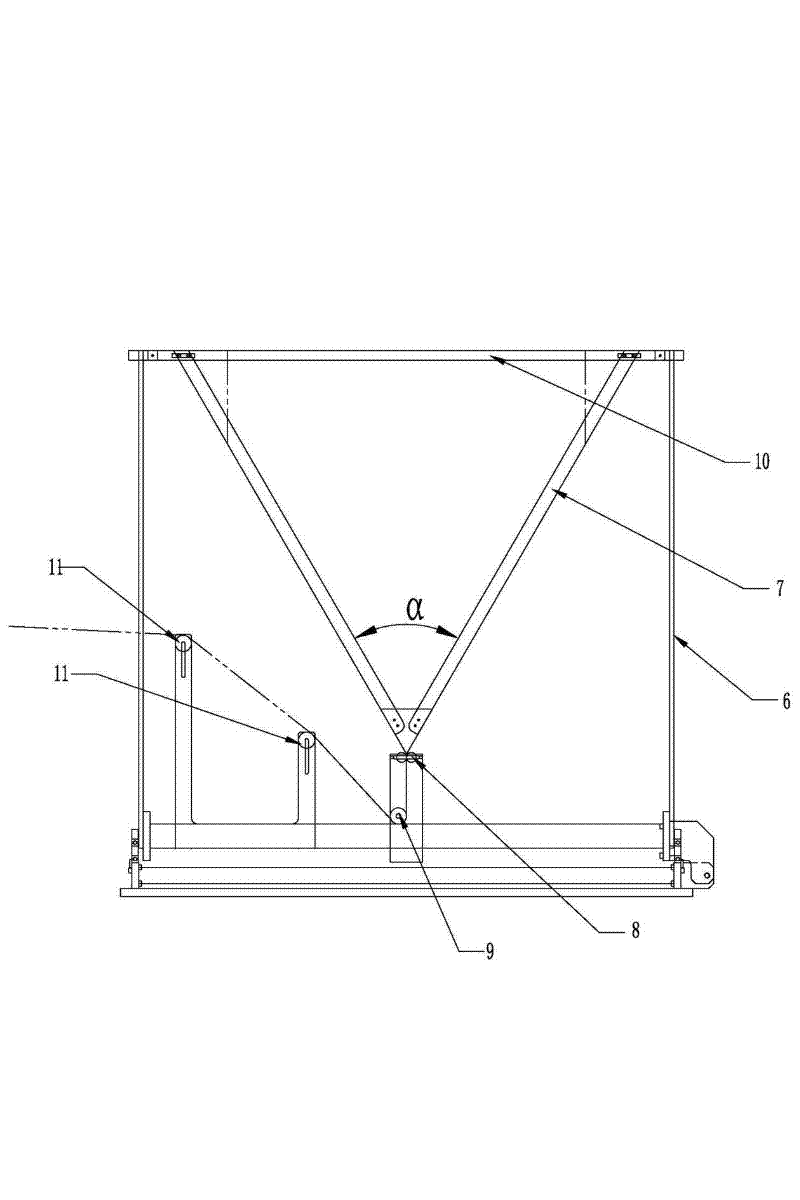

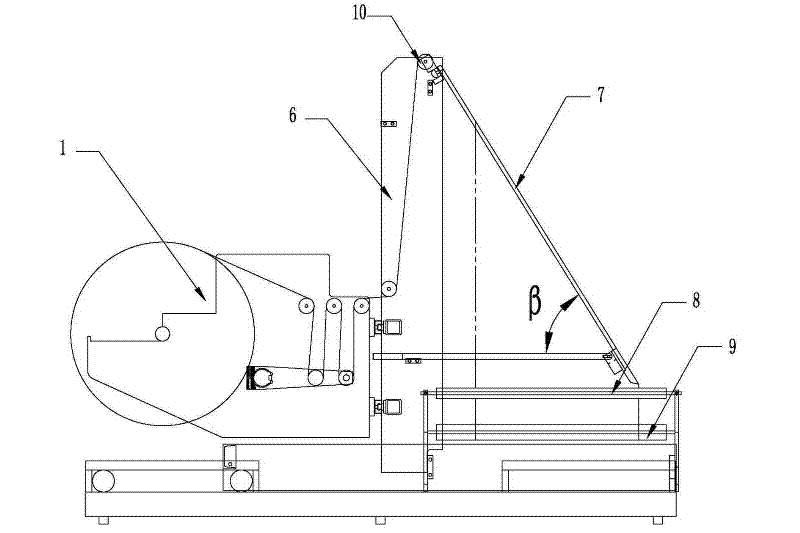

[0009] Such as figure 1 , figure 2 and image 3 As shown, an electrostatic film bottom seal bag making machine includes a feeding device 1, a tension device 2, a longitudinal sealing device 3 and a bag cutting device 4, and is characterized in that a hemming device is arranged between the feeding device 1 and the tension device 2 5. The hemming device 5 includes a frame 6, a hemming tripod 7, a pinch roller 8, a guide roller 9, a lead-in roller 10 and a lead-out roller 11; Folding tripod 7 is an equilateral triangle, the angle of its vertex α is 60 °, and the angle β of the bottom of folding tripod 7 and frame 6 is 55 °; On the upper frame 6, two pinch rollers 8 are installed on the frame 6 below the hemming tripod 7, the guide rollers 9 are installed on the lower side of the two pinch rollers 8, and the two lead-out rollers 11 are installed on the guide rollers in turn. 9 on the left.

[0010] The working principle of the present invention is as follows: the packaging ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com