Device for coating substrates by means of high speed flame spraying

A high-speed flame spraying and equipment technology, used in coatings, melt spraying, spraying devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

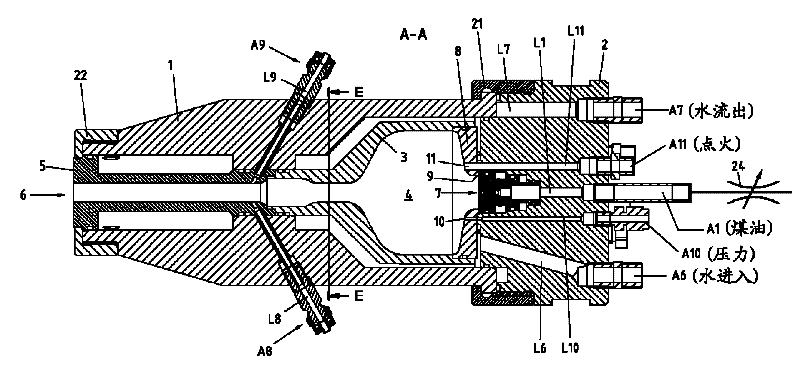

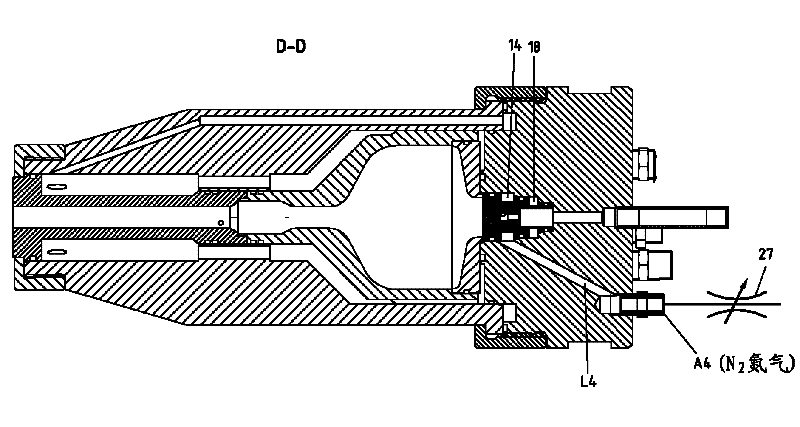

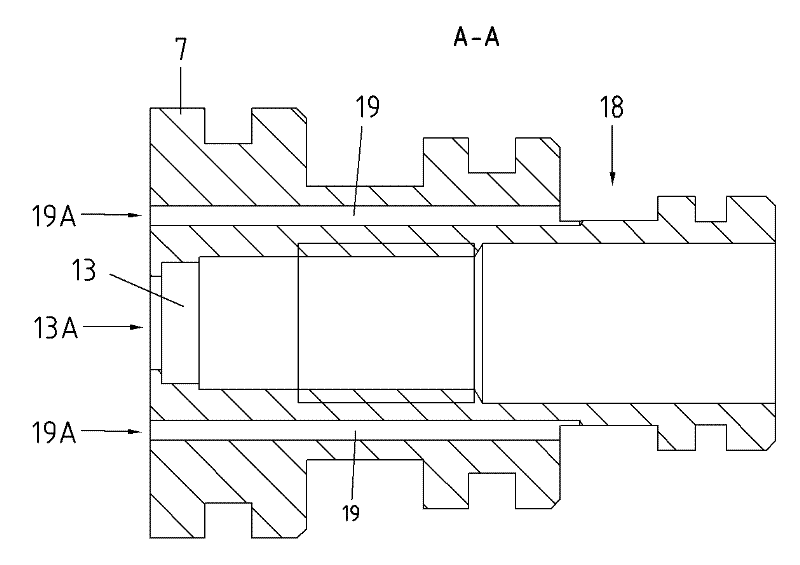

[0063] now refer to figure 1 , shows in a view from the rear an apparatus for coating a substrate by high velocity flame spraying. The plant generally consists of the actual burner and the means of supplying the coating material to be melted and applied. From such as figure 1 It is evident from the illustration shown that the rear of the device has several connectors for the supply of the medium required to operate the burner, as well as for the connection of the pressure sensor and additionally for the connection of the igniter. It is understood that the number and arrangement of connectors may vary. In this example, connectors A1 to A9 are provided for the supply medium, i.e., A1 Liquid fuel, A2 Oxygen, A3 Oxygen, optional, A4 Nitrogen, A5 Gas fuel, A6 Cooling water in, A7 Cooling water out, A8 Powder, A9 powder. It will of course be understood that instead of the above-listed media other liquid or gaseous media may be supplied via the connectors A1 to A7. Connector A10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com