Automatic screw locking device with elastic chuck

An elastic collet and automatic assembly technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult manual operation, slow speed, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

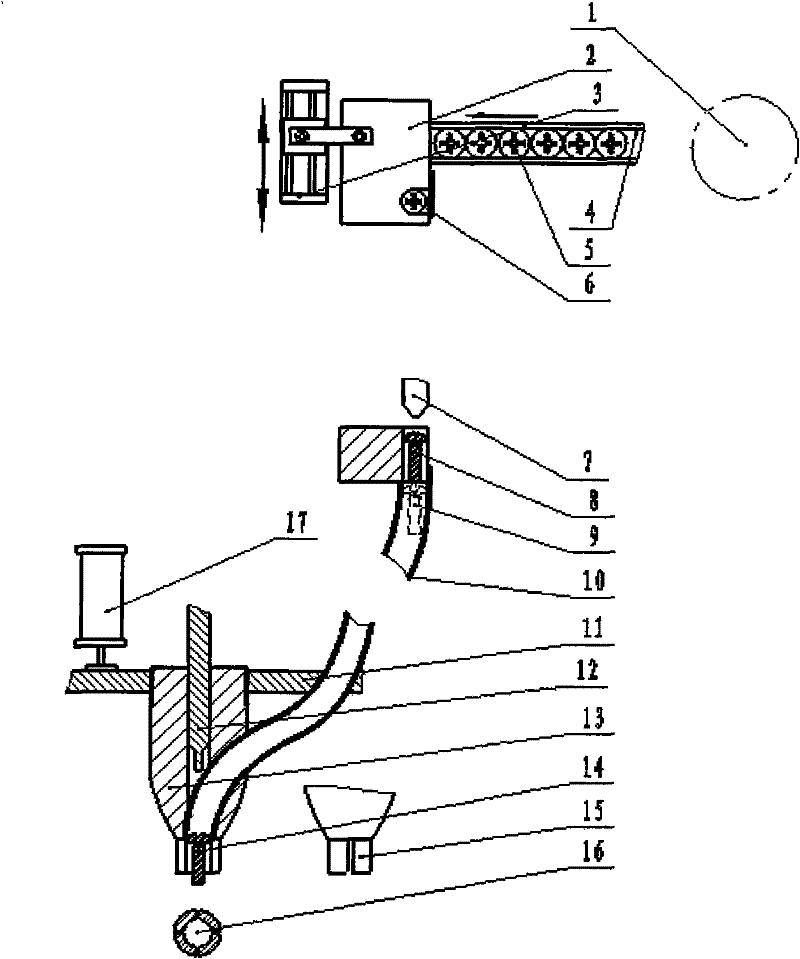

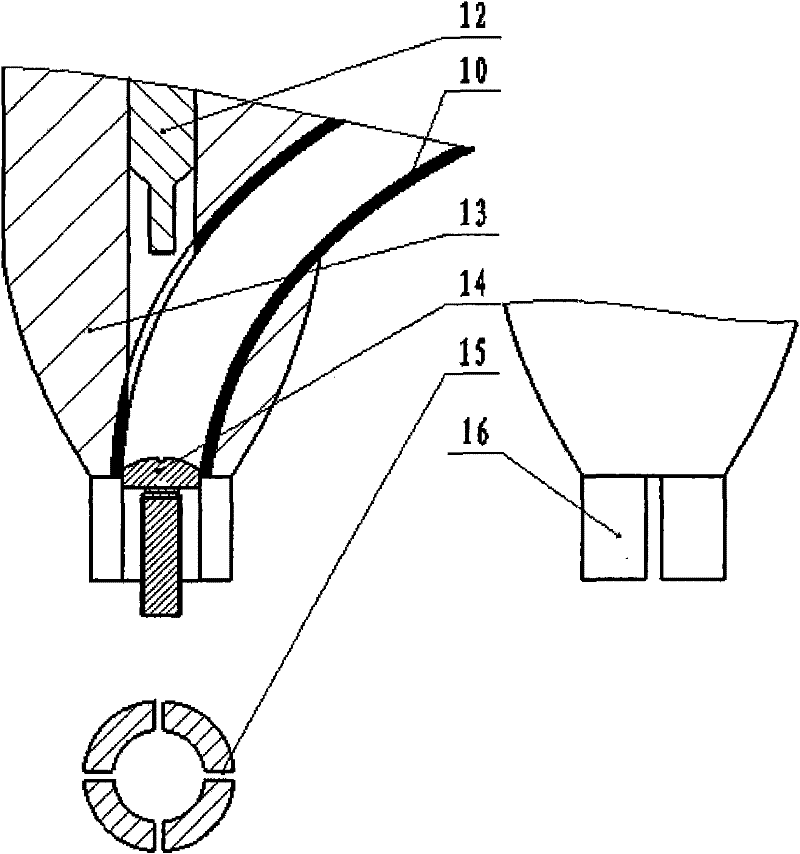

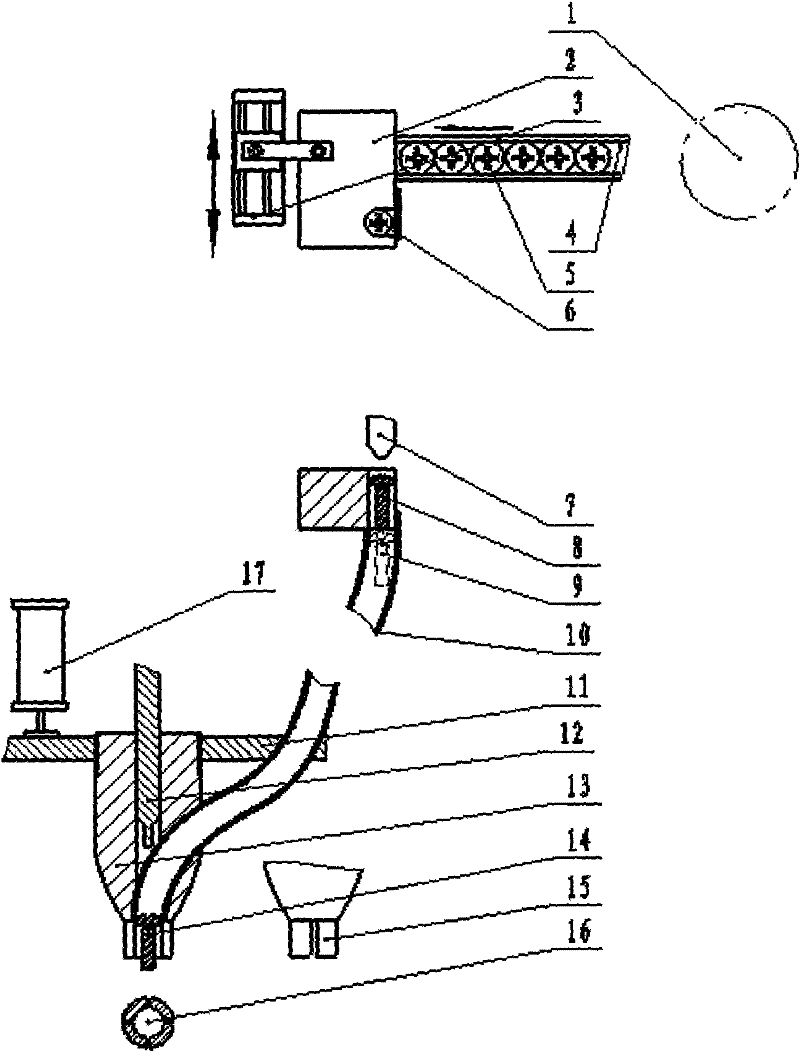

[0012] figure 1 The upper part is the top view of the structural schematic diagram, and the lower part is the main view. like figure 1 As shown, the scattered screws are arranged orderly and neatly in the screw conveying groove (4) under the sub-resonant state of the vibrating feeder (1). The screw separation hole (6) on the side of the screw separation block (2) in contact with the screw delivery groove (4) can only accommodate one screw (8). When the slide table cylinder (3) drives the screw separation block (2) to When moving in the direction a, only one screw (8) will be pushed into the screw separation hole (6) under the action of the vibrating feeder (1), and when the screw separation block (2) moves in the direction b, this Only screw (9) is delivered to the below of high-pressure air injection port (7), and is also the uppermost end of nail-injecting flexible pipe (10) simultaneously. After the screw (9) is judged by the sensor, the control system controls the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com