Ink jet recording process

一种喷墨记录方法、喷墨记录的技术,应用在复制/标记方法、油墨、印刷等方向,能够解决尚未确立等问题,达到速干性优异、提高耐擦伤、降低渗色的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

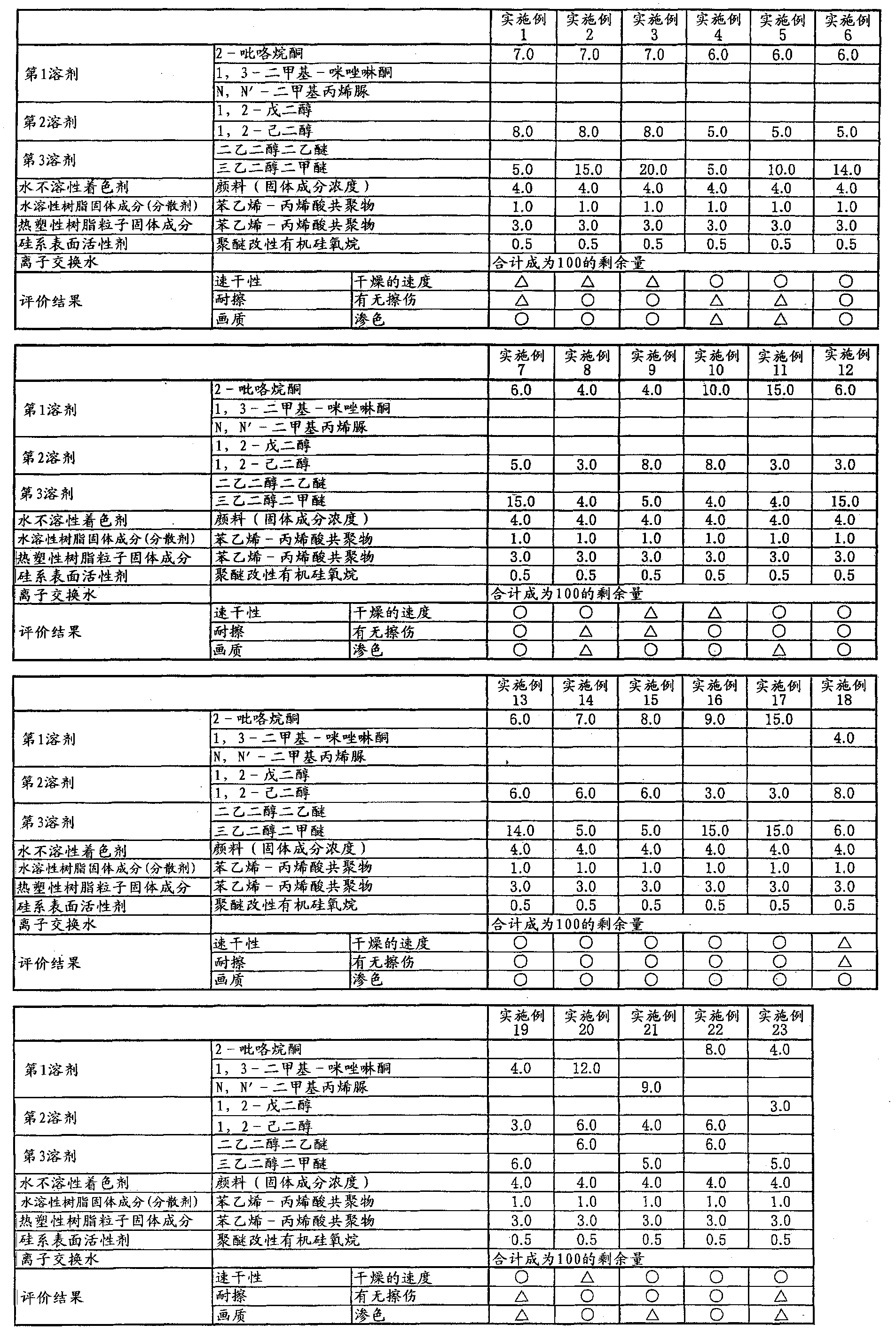

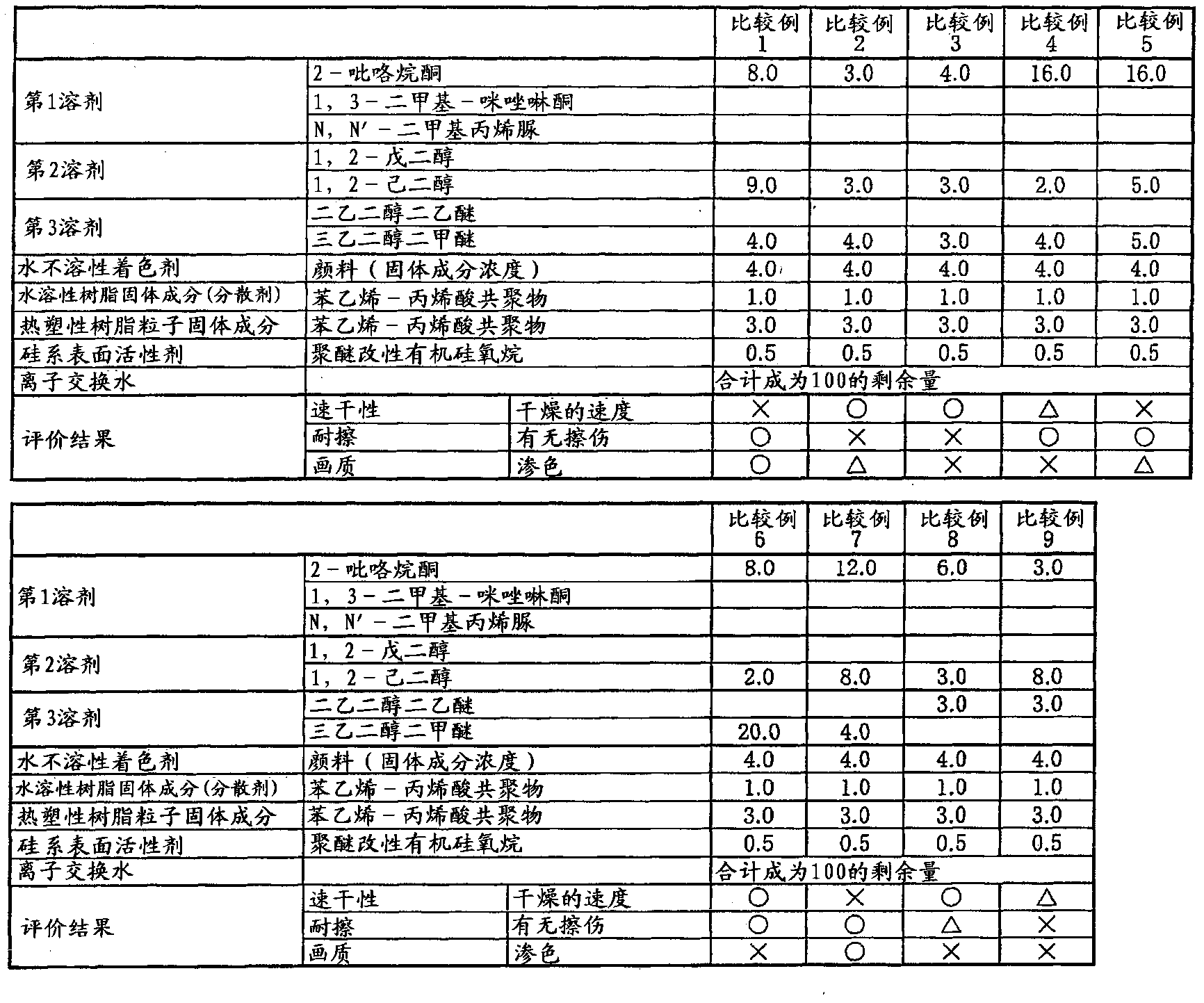

Examples

Embodiment Construction

[0029] Hereinafter, preferred embodiments of the present invention will be described. The embodiments described below are examples for explaining the present invention. In addition, this invention is not limited to the following embodiment, Various modification examples implemented in the range which do not change the summary of this invention are included.

[0030] 1. Inkjet recording method

[0031] An inkjet recording method according to an embodiment of the present invention is characterized in that the inkjet recording method includes heating a recording medium formed of a polyvinyl chloride film to a temperature range of 40° C. to 60° C. by an inkjet recording apparatus. Above, the first process of ejecting the droplets of the water-based ink composition described later, and heating the recording medium to a temperature range of 40°C to 60°C, and combining the water-based ink ejected on the recording medium The second process of object drying; wherein, the water-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com