Anti-fake self-locking bottle cover

A bottle cap and self-locking technology, which is applied in the field of bottle caps, can solve the problems of difficult thread making, easy damage, liquid leakage in the bottle, etc., and achieve the effects of good liquid sealing, good storage and firm installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

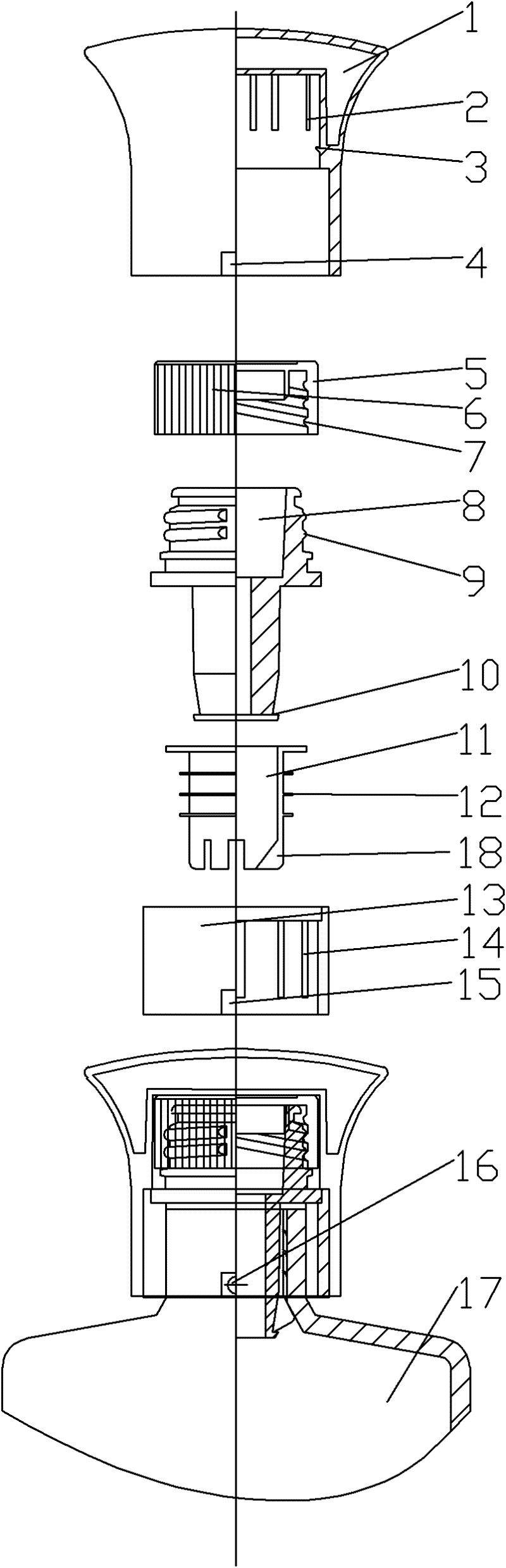

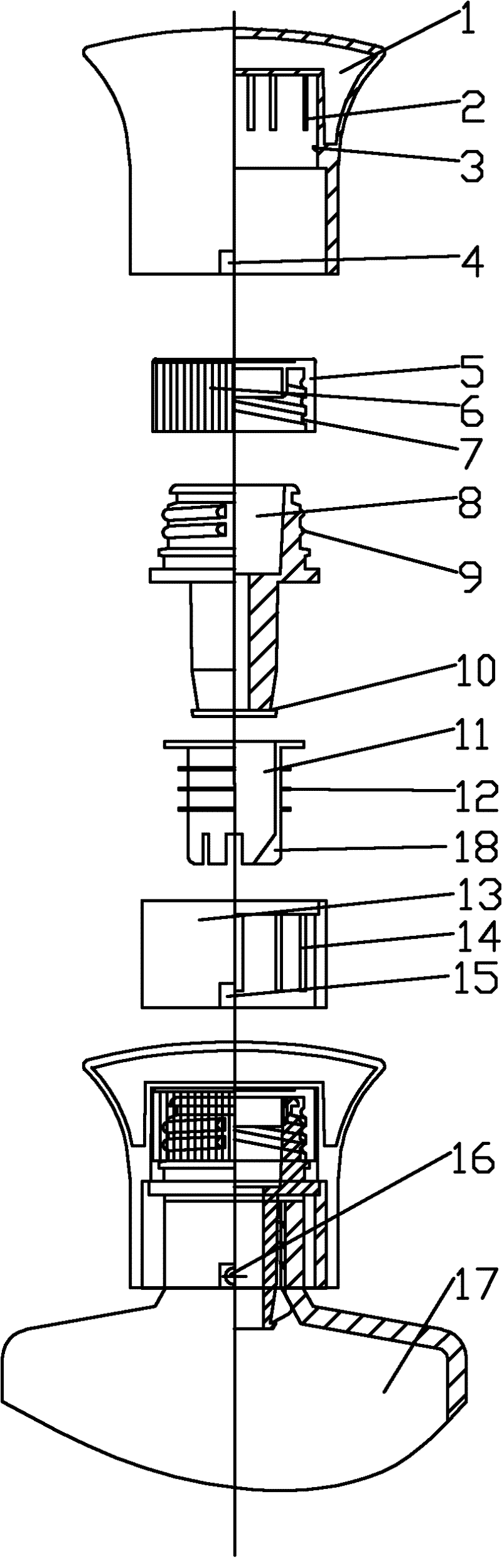

[0012] Such as figure 1 In an anti-counterfeiting self-locking bottle cap, the inner cap 5 is installed in the housing 1, the inner cap 5 is connected with the connecting cap 8 through threads, and the outer surface of the lower end of the connecting cap 8 is matched with the inner surface of the inner plug 11; 8 Hollow, with threads on the upper end, a tapered section at the lower end, and a stop groove 10 under the tapered section; the outer surface of the inner plug 11 is provided with a plurality of sealing rings 12, and the lower end is provided with a plurality of wedges 18.

[0013] The wedges 18 are evenly distributed on the circumference of the lower end of the inner plug 11, the outer side of the wedge 18 is parallel to the axis of the inner plug 11, and the inner side shrinks toward the axis.

[0014] A two-way housing 13 is also installed outside the housing 1, a plurality of positioning bars 14 are provided on the inner surface of the two-way housing 13, and an outer g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com