Fishbone-shaped groove rubber-coated roller

A rubber-covered roller and herringbone-shaped technology, which is applied in the direction of transportation and packaging, conveyor objects, rollers, etc., can solve the problems of easy aging, insufficient adhesion of the roller and the rubber surface, and low tear resistance, and achieve anti-tearing. The tearing ability is improved, the extrusion deformation is small, and the friction coefficient is not reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

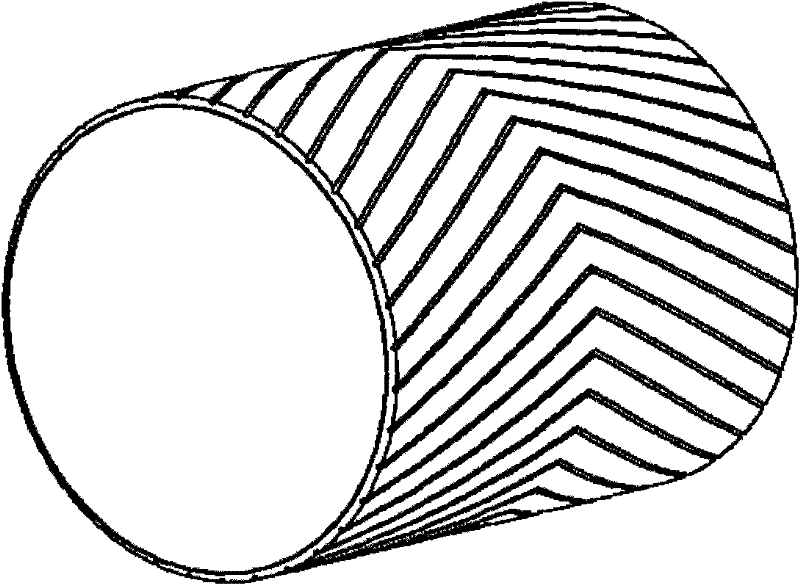

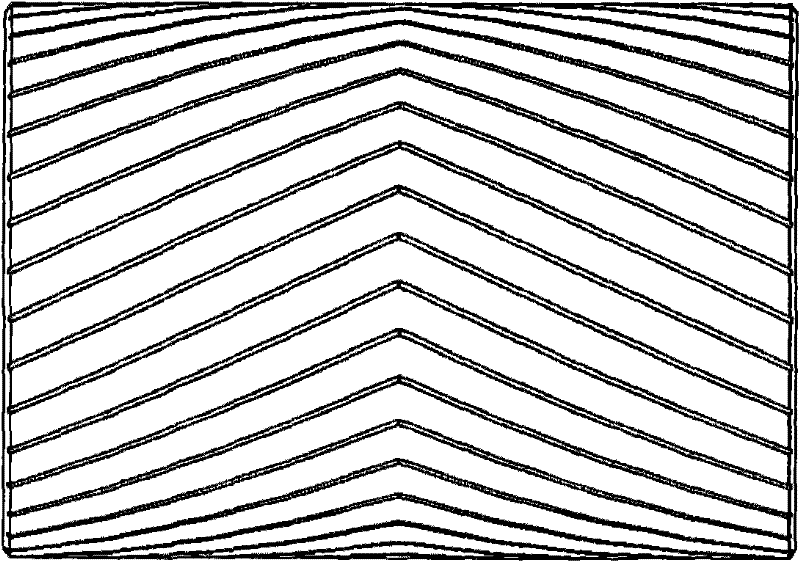

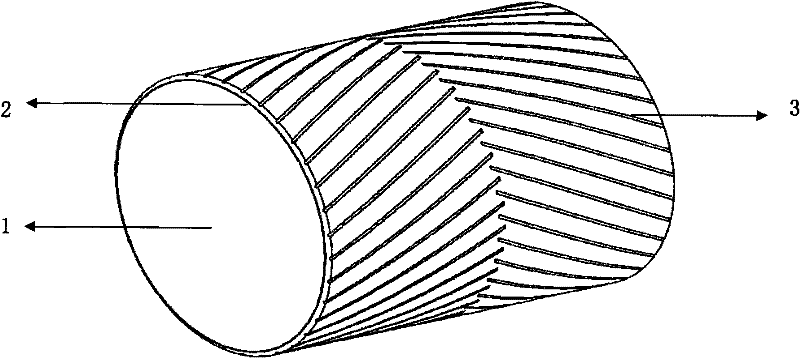

[0016] Such as image 3 As shown, the herringbone-groove rubber-covered roller involved in this embodiment includes a roller body 1 made of metal, and a layer of integral rubber-covered 2 is wrapped on the outer peripheral surface of the metal roller. Strip grooves 3 are provided on the left and right sides of the rubberized surface, and the grooves on the left and right sides are staggered at the center line of the drum body; the top view of the rubberized drum is shown in Figure 4 . When using the rubberized roller of this embodiment, since the strip grooves on the left and right sides of the surface of the roller do not intersect, the extrusion deformation of this type of rubberized rubber surface is smaller than that of the herringbone grooved rubber surface, and the tear resistance is improved; at the same time, the conveying When the belt is in contact with the surface of the pulley, the water and dirt on the surface of the rubberized pulley can be discharged from the ...

Embodiment 2

[0018] The herringbone groove rubberized roller involved in this embodiment includes a roller body 1, the roller body is made of metal, and a whole layer of rubberized rubber 2 is wrapped on the outer peripheral surface of the metal roller, and the rubberized surface The left and right sides are provided with strip grooves 3, and the grooves on the left and right sides are staggered at the center line of the drum body, and the lengths of the strip grooves on the left and right sides are the same. When using the rubberized roller of this embodiment, since the strip grooves on the left and right sides of the roller surface do not intersect, the extrusion deformation of this type of rubberized rubber surface is smaller than that of the herringbone grooved rubber surface, and the tear resistance is improved. At the same time, because The strip grooves on the left and right sides have the same length, which makes the manufacturing process more convenient and the force on the rubberi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com