An Improved Miniaturized Membrane Valve

A membrane valve and valve body technology, applied in the field of improved miniaturized membrane valves, can solve problems such as channel blockage, and achieve the effects of easy disassembly, reduced resistance, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

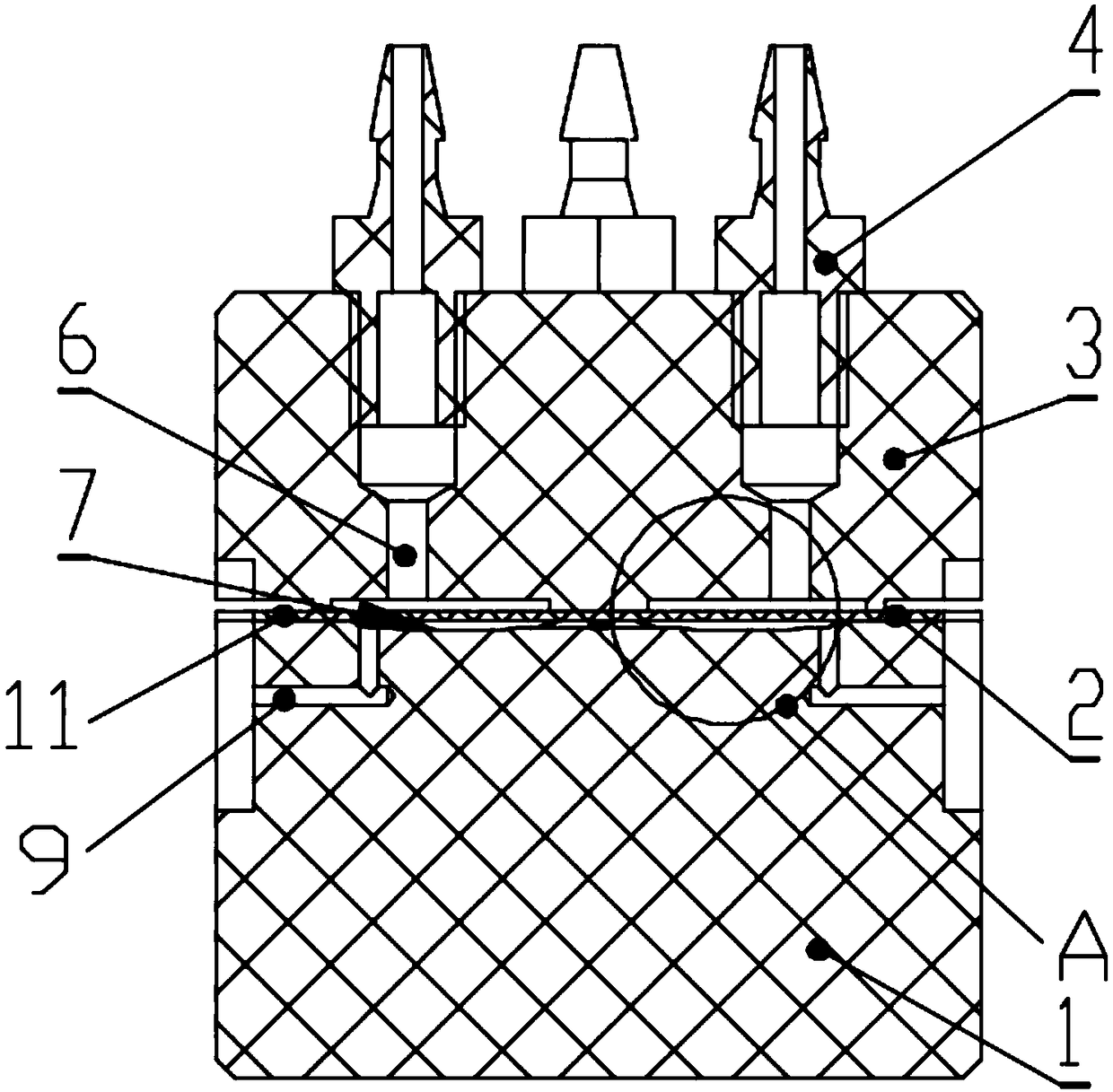

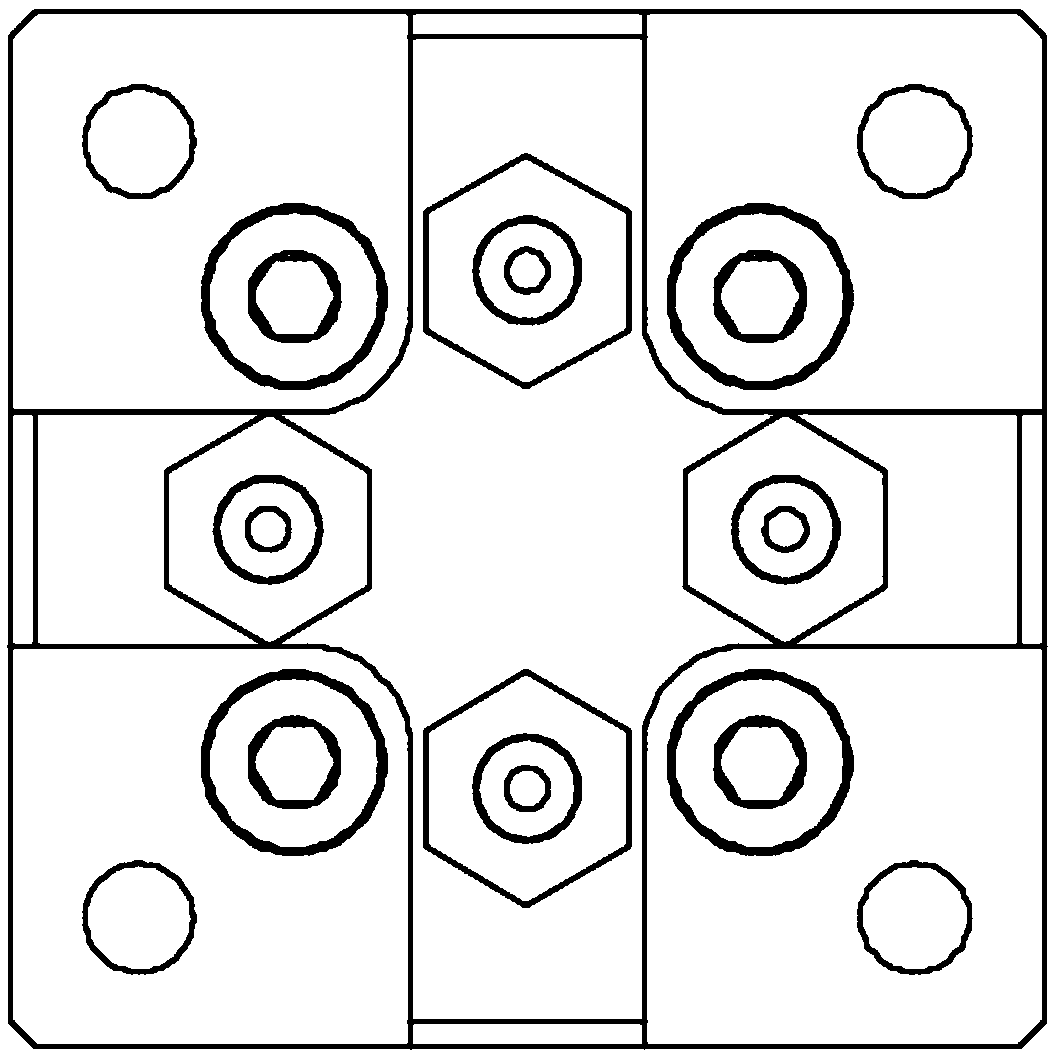

[0060] Such as Figure 1-8 As shown, it is a multi-channel valve. The valve system is arranged in a cross shape to form multiple channels, including an upper valve body 3, a lower valve body 1, and a flexible membrane 2 sandwiched between the upper and lower valve bodies. The flexible membrane 2 can It is made of raw rubber or silicon rubber; the upper and lower valve bodies are connected by four screws 5; the positions of the four screws 5 are evenly arranged in two diagonal directions.

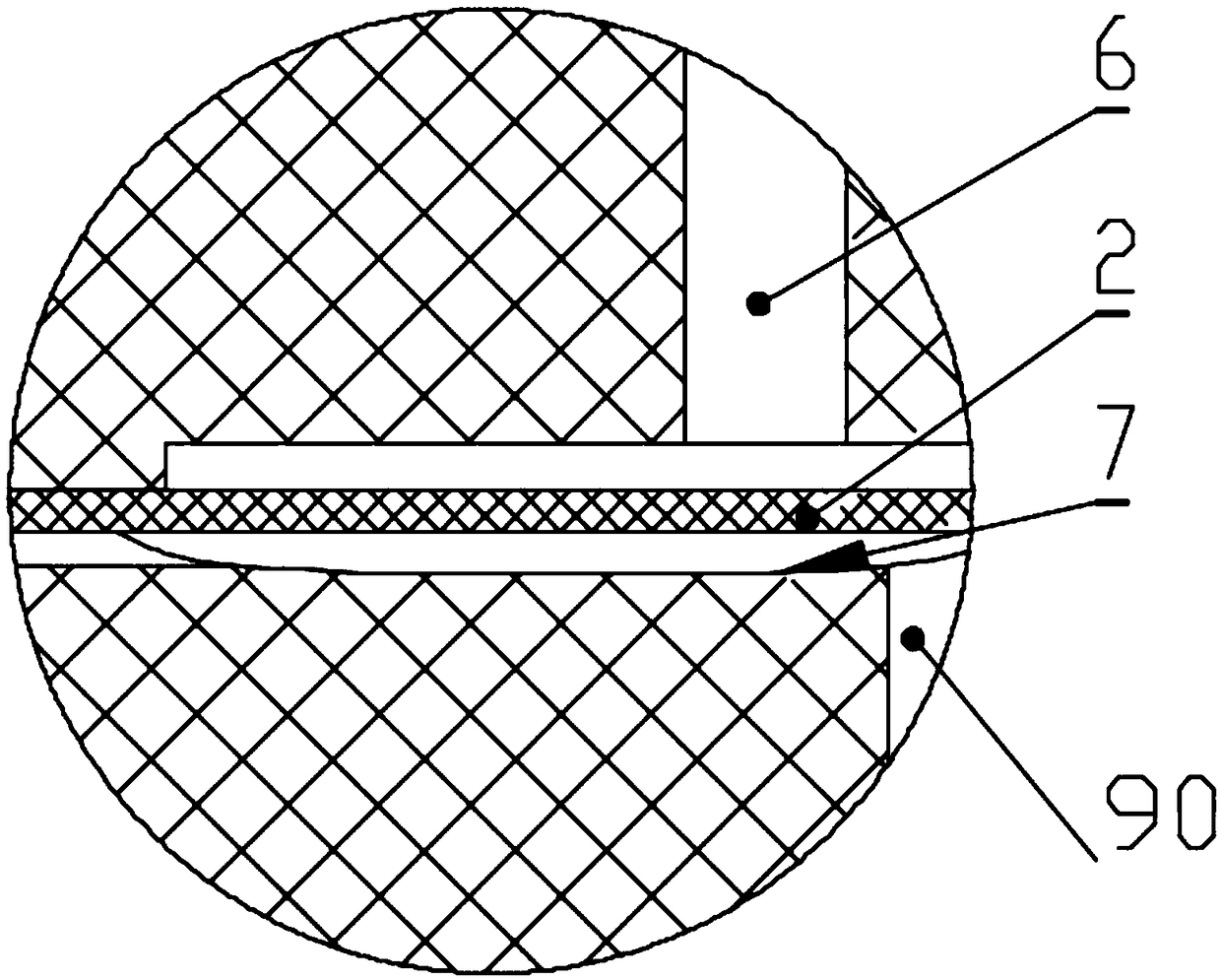

[0061] The upper and lower valve bodies are provided with a valve system, and the valve system includes: a connector 4, an air pipeline 6, a fluid cavity 7, and a fluid pipeline 9; the connector 4 is installed on the upper valve body 3, and the upper end Protruding above the upper valve body 3, the lower end penetrates the upper valve body 3 and is connected with the built-in air pipeline 6 of the upper valve body 3, and the air pipeline 6 is connected to the upper surface of the flexible me...

Embodiment 2

[0069] Such as Figure 9-13 As shown, the main difference between this embodiment and Embodiment 1 is that the boss 11 is arranged on the surface of the lower valve body 1 , specifically located outside the edge of the fluid chamber 7 , and its functions and effects are the same.

[0070] As a further improvement, such as Figure 13-16 As shown, at least one barrier 12 (such as Figure 14 shown). The barrier 12 includes embedded limiting components or the flexible membrane 2 is partially thickened and rigidized. The barrier 12 prevents compressed air from flowing from one air line 6 into any adjacent air line 6 .

[0071] Described lower valve body 1 is also provided with groove 13 (as Figure 15 shown) for embedding the barrier 12 in the groove 13; or the partially thickened and rigidified flexible membrane 2 directly protrudes into the upper valve body 3 as the barrier 12 (as Figure 16 shown).

Embodiment 3

[0073] Such as Figure 17-27 As shown, the difference between this embodiment and Embodiment 1 or 2 is that the boss 11 is arranged on the upper valve body 3, the boss 11 includes a platform 16 and a protrusion 18, and the platform 16 is arranged on the protrusion 18; the height of the platform 16 is slightly lower than the protrusion 18, but protrudes from the surface of the valve body; a groove body 14 is set on the lower valve body 1, and the groove body 14 is arranged on the protrusion and On the other valve body opposite to the portion 18 , the groove body 14 is engaged with the protruding portion 18 .

[0074] When the upper valve body 3 and the lower valve body 1 are pressed tightly, the protrusion 18 squeezes the flexible membrane 2 around the fluid chamber 7 into the groove body 14, thereby forming a stretching effect on the flexible membrane 2 above the fluid chamber 7, thereby It effectively prevents the flexible membrane 2 from being compressed and squeezed into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com