Extra-large-span cross-section-variable pre-stressed normally placed evacuating quadrangular pyramid space grid and manufacturing method thereof

A prestressed, variable section technology, applied in the direction of buildings and building structures, can solve the problems that rigid grid structures are difficult to achieve safety, rationality, advanced, economical, large amount of steel, and high cost, and reduce structural use. The effect of reducing the amount of steel, reducing the amount of steel and saving the project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

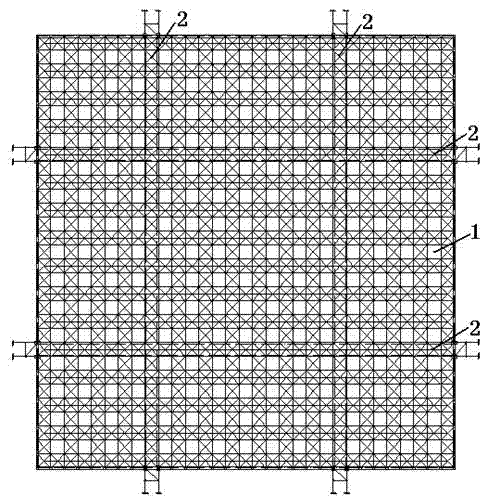

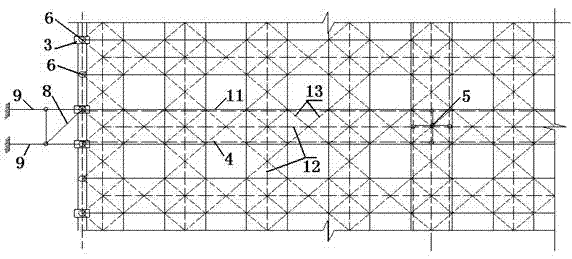

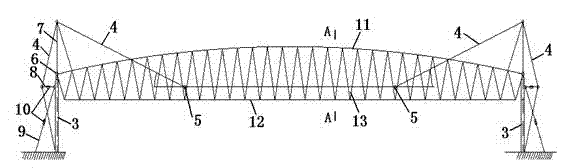

[0022] Example 1. Such as figure 1 , 2 As shown, it includes the double-layer network frame 1 with positive discharge and evacuation of quadrangular pyramid with variable cross-section, from figure 1 It can be seen that each direction ( X , Y Direction) 16 variable cross-section space trusses are formed orthogonally, and 15×15=225 grids are evacuated, that is, the evacuated area reaches 225×25=5625㎡, accounting for 25% of the total roof area. The reduction in material usage is obvious. From image 3 It can be seen that the total height of the structure is also reduced by about 40% compared with the conventional three-layer flat grid. Due to the evacuation of the structure and the reduction of the structure height, the amount of steel used is reduced, but the rigidity is also reduced accordingly, which will not meet the requirements of the structure. In order to solve this problem, the present invention adopts the roof cable-stayed prestressing method to make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com