Rear-mounted rigid wall-connecting device

A wall-connecting and rigid technology, applied in the field of post-mounted rigid wall-connecting devices, can solve the problems of not being able to meet the requirements of bearing capacity, difficult to adjust the vertical direction, and easy to be removed by workers at will, so as to ensure safe use, convenient processing, The effect of great endurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

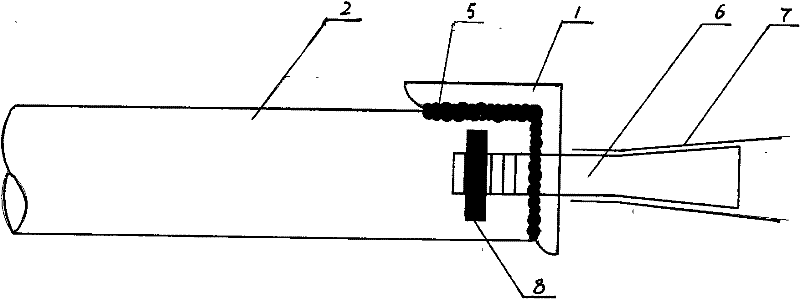

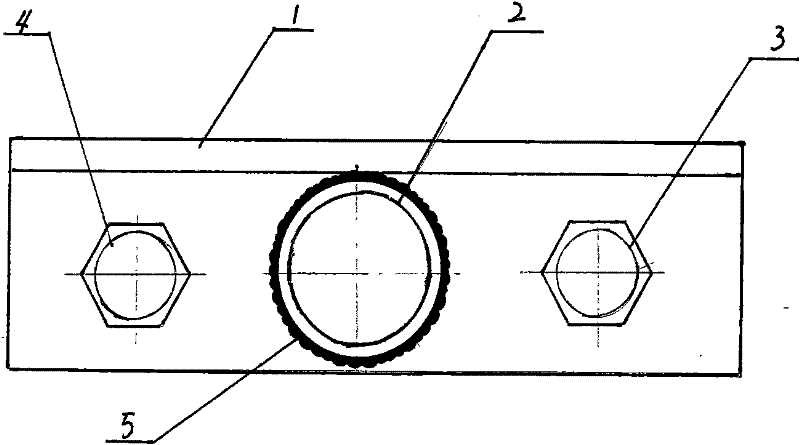

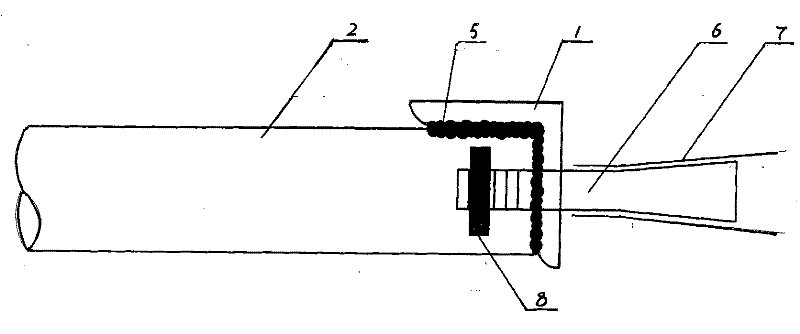

[0013] exist Figure 1~2 Among them, a steel pipe 2 is welded on the angle steel 1, and the angle steel and the steel pipe are connected by a weld 5. There are round holes 3 and 4 respectively on both sides of the steel pipe, and expansion bolts 6 are inserted in the round holes 3 and 4 respectively. The small head of the expansion bolt passes through the round hole of the angle steel and is placed inside the hole, and the large tail of the expansion bolt is put on the open pipe 7 and placed outside the hole. When in use, drive the expansion bolt into the concrete wall, put the angle steel welded with the steel pipe on the expansion bolt through the round hole, and then tighten the lock nut 8 in the expansion bolt to lock the wall connecting device on the concrete wall superior. The free end of the steel pipe of the wall-connecting device is fastened to the vertical pole through the fastener, and the frame body is connected with the construction engineering structure, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com