Automatic passive fire protection spraying valve

A sprinkler valve and fire protection technology, applied in valve details, valve devices, engine components, etc., can solve problems such as waste of water resources, cutting off water sources, narrow temperature range, etc., to improve spraying effect, avoid false opening, and delay spraying The effect of shower time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

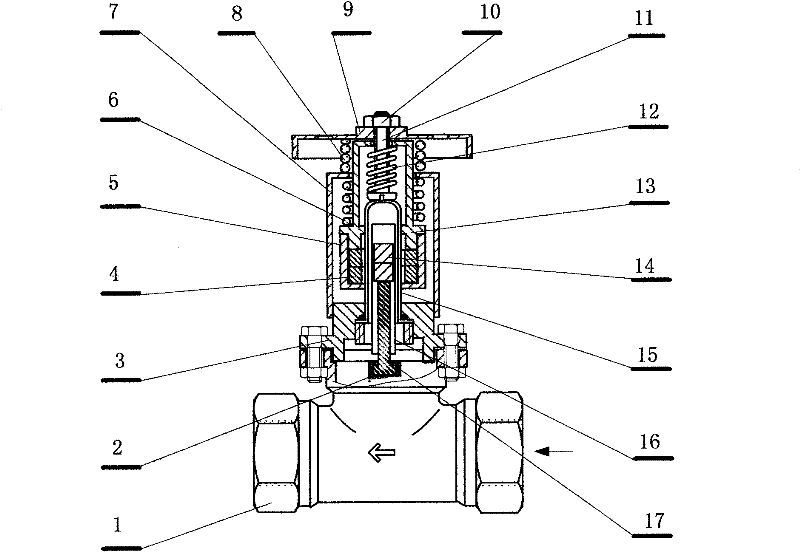

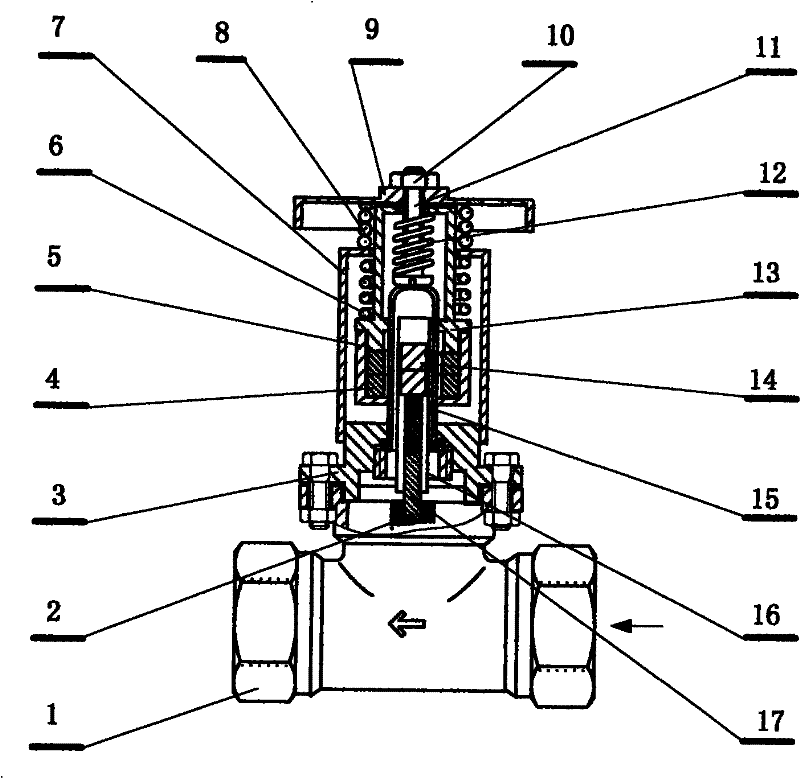

[0008] The accompanying drawing is a schematic structural diagram of the present embodiment. The invention consists of a valve body (1) and a temperature control head. It mainly includes valve body (1), piston sealing ring (2), valve cover (3), magnetic ring assembly (4), magnetic ring sleeve (5), return spring (6), valve cover (7), memory alloy ( 8), heat collecting cover (9), adjusting nut (10), pressure rod (11), compression spring (12), inner sleeve (13), magnetic column assembly (14), valve core outer cover (15), valve core Cover (16), piston rod (17); there is a cylindrical water outlet in the valve body (1), and a piston diaphragm is installed on the upper end of the water outlet, and there is a pressure relief hole on the piston diaphragm and the bottom of the piston rod (17) Cooperate with the piston sealing ring (2), a small through hole on the piston diaphragm communicates with the water inlet of the valve body (1); the piston rod (17) presses the magnetic rod asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com