High-power compound-eye type concentrator solar cell module

A technology of solar cell components and solar cells, which is applied in the field of solar photovoltaic power generation, can solve the problems of inability to use scattered radiation, increase in cost, and large size, and solve the problems of high-power concentration and system heat dissipation, realize automatic production, and improve production technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

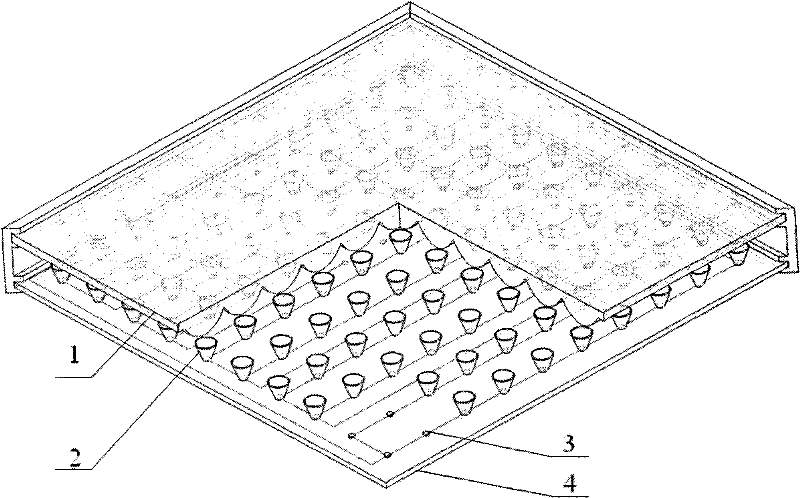

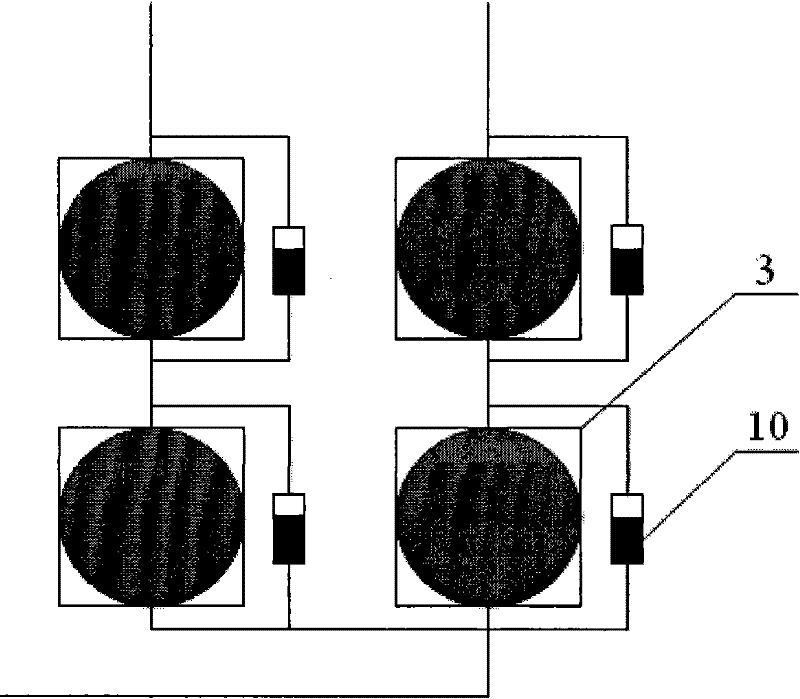

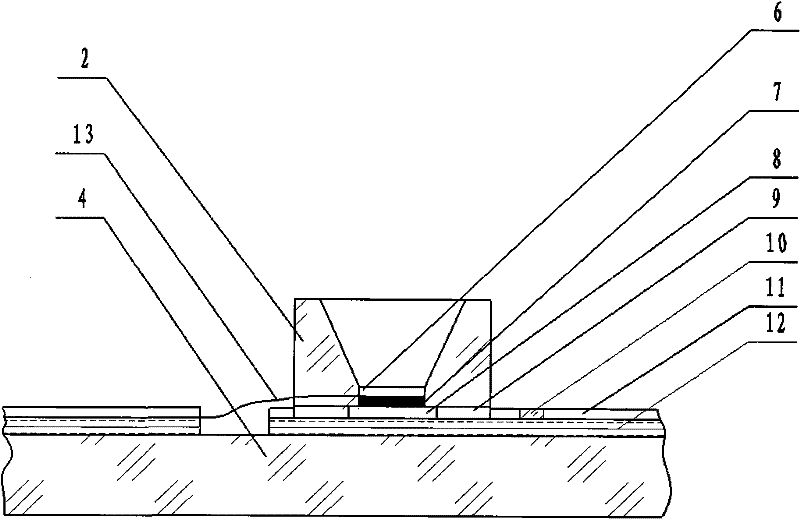

[0018] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Embodiments of the present invention include a fly-eye microlens concentrator, a non-imaging secondary concentrator, a concentrating solar cell chip, and a glass-based circuit board. Among them, the concentrating solar cell chip is welded on the glass-based circuit board, corresponding to the focus of each lens of the fly-eye microlens concentrator; the non-imaging secondary concentrator is located directly above each concentrating solar cell chip, and can The light is focused on the concentrating solar cell chip for the second time; the copper plating on the glass-based circuit board is engraved with a circuit, and the concentrating solar cell chips soldered on it are connected in series or in parallel.

[0019] image 3 The partial cross-sectional view of this embodiment shown shows an arrangement structure and heat dissipation method of the non-imaging secondary concentrator, concentrating solar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com