Novel lodinated resin manufacturing process and product

A manufacturing method, resin technology, applied in the field of new iodinated resin manufacturing and products, which can solve the problems of environmental unfriendliness, negative environmental consequences, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

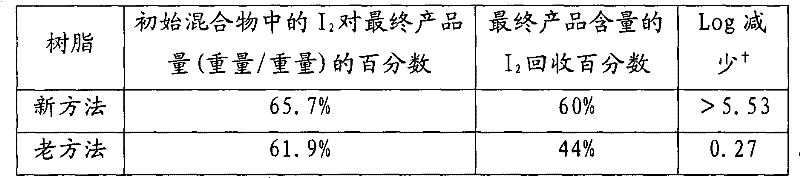

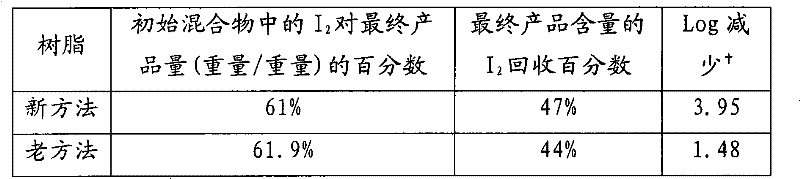

[0019] The present invention provides a new method for manufacturing activated resin particles, which have a wide range of uses in various disinfectants and antimicrobial and antiviral products. The present invention also provides a new activated demand-type disinfectant iodinated resin, which has superior properties than resins known in the art. Preferably, the iodinated resin is an iodinated resin. The new manufacturing method of the present invention is efficient and environmentally friendly. In addition, the manufacturing method produces an antimicrobial iodinated resin with better overall performance (higher efficacy) than the resin produced by the prior art method, which is due to the higher iodine degree and Higher iodine content uniformity when comparing particles and particles.

[0020] Production method

[0021] In one embodiment of the present invention, the iodinated resin can be prepared roughly as follows:

[0022] i. Obtain micronized anionic resin by jet milling p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com