Tobacco-seedling ridge-height self-adaptable automatic-guiding transplanter

An automatic guidance and self-adaptive technology, applied in the field of agricultural machinery, can solve the problems of low work efficiency, high cost of manually transplanting tobacco seedlings, and cumbersome machines, so as to achieve stable and accurate transplanting spacing, improve the survival rate of tobacco seedlings, and ensure depth. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

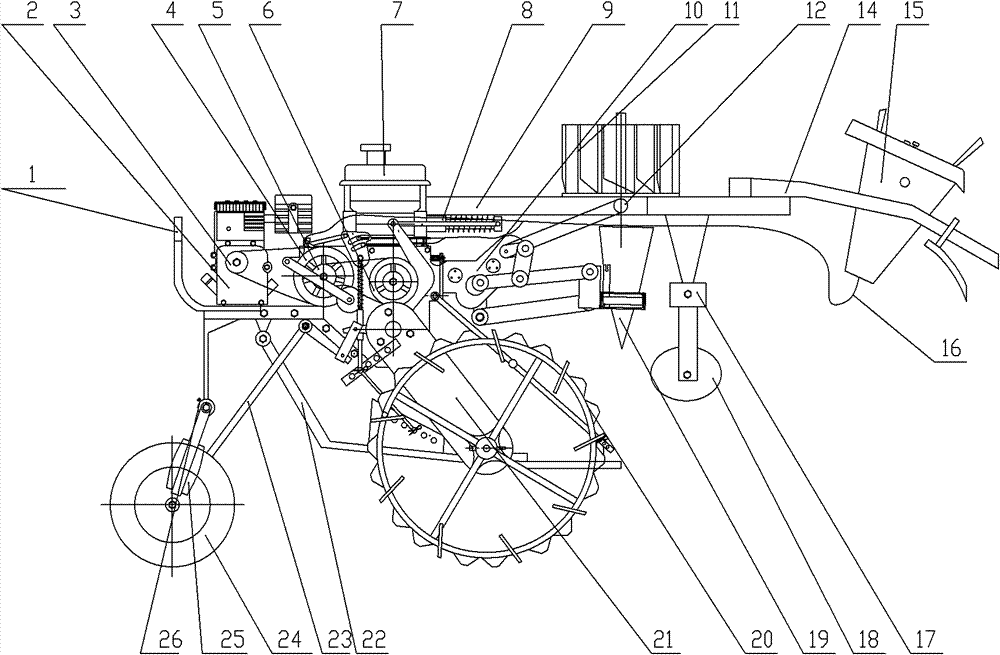

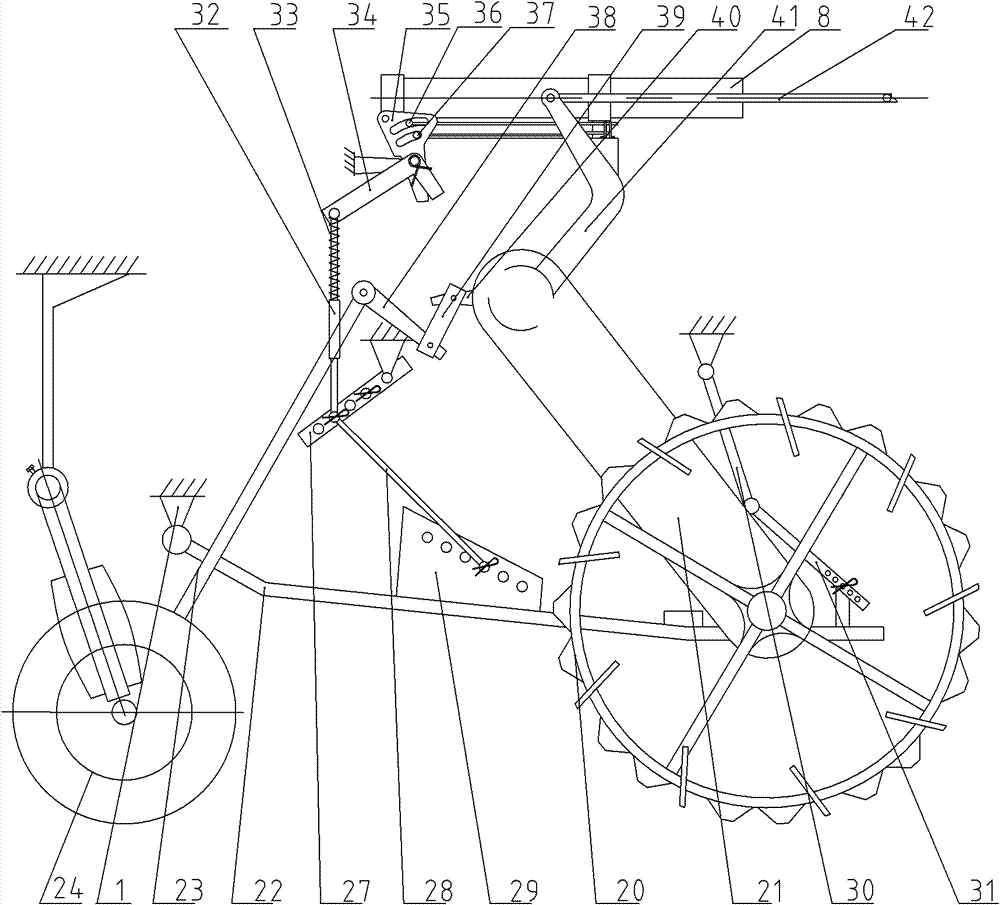

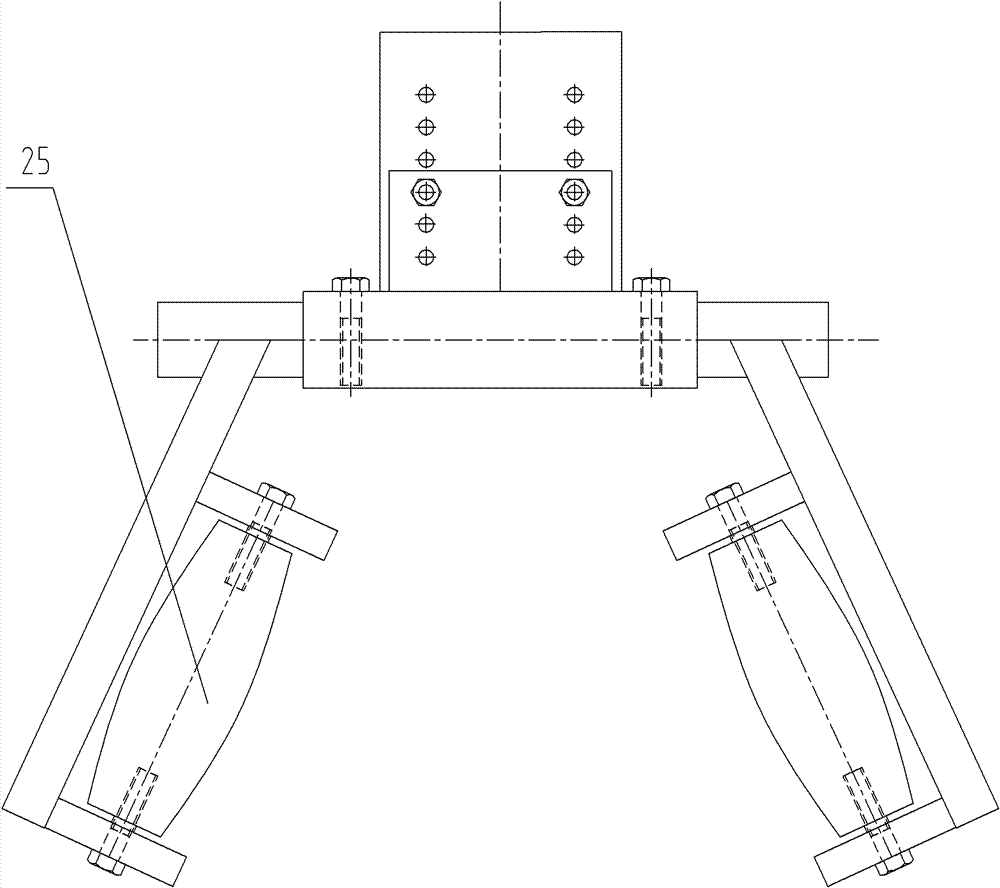

[0029] see figure 1 , figure 2 , including frame 1, engine 2, first pulley 3, belt, second pulley 4, third pulley 5, fourth pulley 6, oil control rod 36, control rod 37, gasoline tank 7, lifting curved arm 41, curved arm Pull rod 42, hydraulic cylinder 8, sensitivity spring 33, seedling throwing frame 48, seedling throwing device 11, handrail 14, console 15, control line 16, soil covering frame 17, soil covering wheel 18, planter 19, ground wheel 20, sprocket wheel Box 21, induction plate position regulator 29, self-adaptive induction plate 22, front wheel support bar 23, front wheel 24, guide wheel 25, guide frame 26, described automatic guide system is provided with on described frame 1 , hydraulic lifting system and ridge height self-adaptive system, front wheel support rod 23 is fixedly connected with front wheel support arm 38, described front wheel support arm 38 is connected with proportional linkage rod 39 and can rotate relatively, and described front wheel support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com