Sandblasting position controlling device

A control device and a sandblasting technology, applied in the field of sandblasting machines, can solve problems such as inability to control sandblasting surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

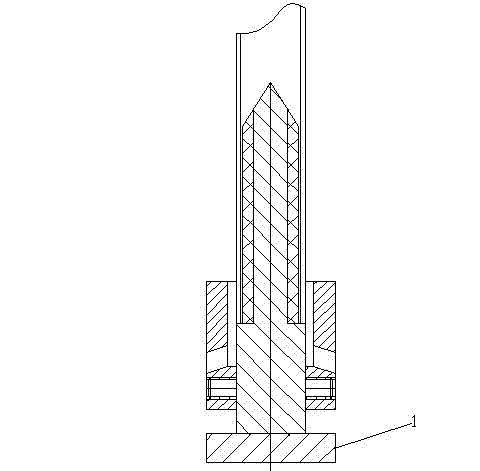

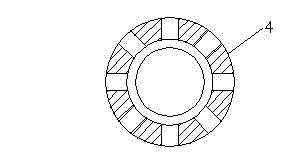

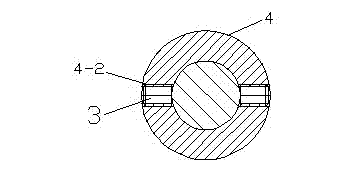

[0010] Such as figure 1 , 2 . As shown in 3, a sandblasting position control device includes a rotating mandrel 2 screwed to the rotating disk 1 of the sandblasting machine, and also includes an outer protective cover 4, which is a circular hollow body. The wall of the body is provided with several sand guide holes 4-1, and the outer protective sleeve 4 is arranged on the lower part of the rotating mandrel 2. A jackscrew hole 4-2 is provided below the sand guide hole 4-1, and two jackscrews 3 fix the outer protective sleeve 4 on the bottom of the rotating mandrel 2.

[0011] In order to protect the inner side of the workpiece, a non-metallic inner protective sleeve 6 is set on the top of the rotating mandrel 2, and the preferred material is polyurethane material.

[0012] For workpieces with different sandblasting heights, the top screw 3 can be unscrewed to adjust the height of the outer protective cover 4. Outer protective cover 4 adopts non-metallic material, and preferr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com