Full automatic dual-purpose single- and double-layer firecracker knotting machine

A fully automatic, single-layer and double-layer technology, which is applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of the single function of the automatic whipping machine and the inability to realize the mechanization of fully automatic whipping and packaging, and achieve simple loading and unloading and high work efficiency High, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0021] This example is a non-limiting example of the present invention.

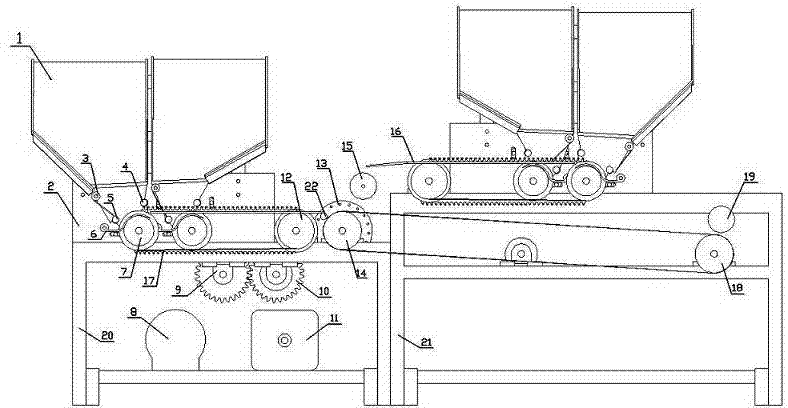

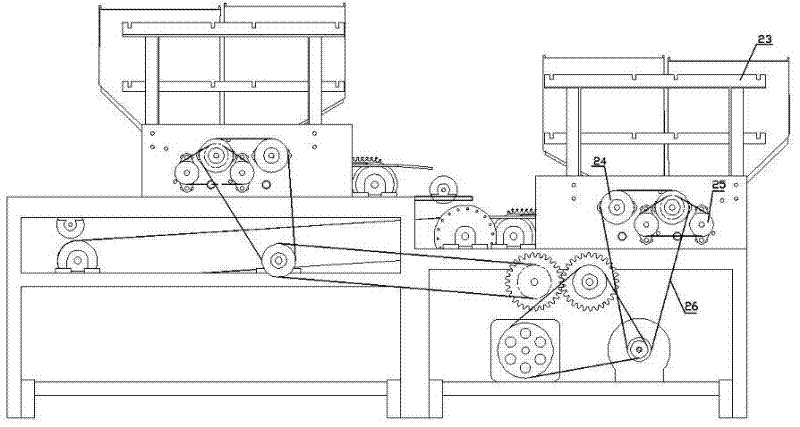

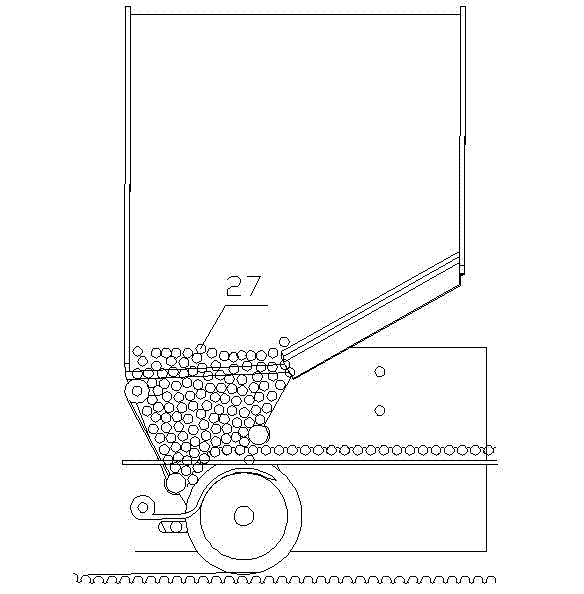

[0022] Such as figure 1 , 2 Shown, the present invention comprises two detachable low frame 20 with height difference, high frame 21, wherein low frame 20 is equipped with power mechanism speed-regulating motor 8 above, also speed change mechanism speed changer 11 is housed. Low frame 20, panel 2 is welded respectively above high frame 21, and panel 2 is equipped with unloading mechanism such as image 3 , Eccentric vibrating mechanism such as Figure 4 , jitter mechanism such as Figure 5 and skipping mechanisms such as Figure 6 , Figure 6 When mentioned for the operation of the skip mechanism. The hopper frame is fixed on the panel 2, and the hopper 1 is fixed on the hopper frame 23.

[0023] Among them such as figure 2 As shown, the speed regulating mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com