A preparation method of fireproof glass fiber-aluminum alloy hybrid laminate

A glass fiber, aluminum alloy plate technology, applied in glass/slag layered products, metal layered products, chemical instruments and methods, etc., to reduce processing costs, integrate fire prevention, and increase fire performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The inventive method comprises the following steps:

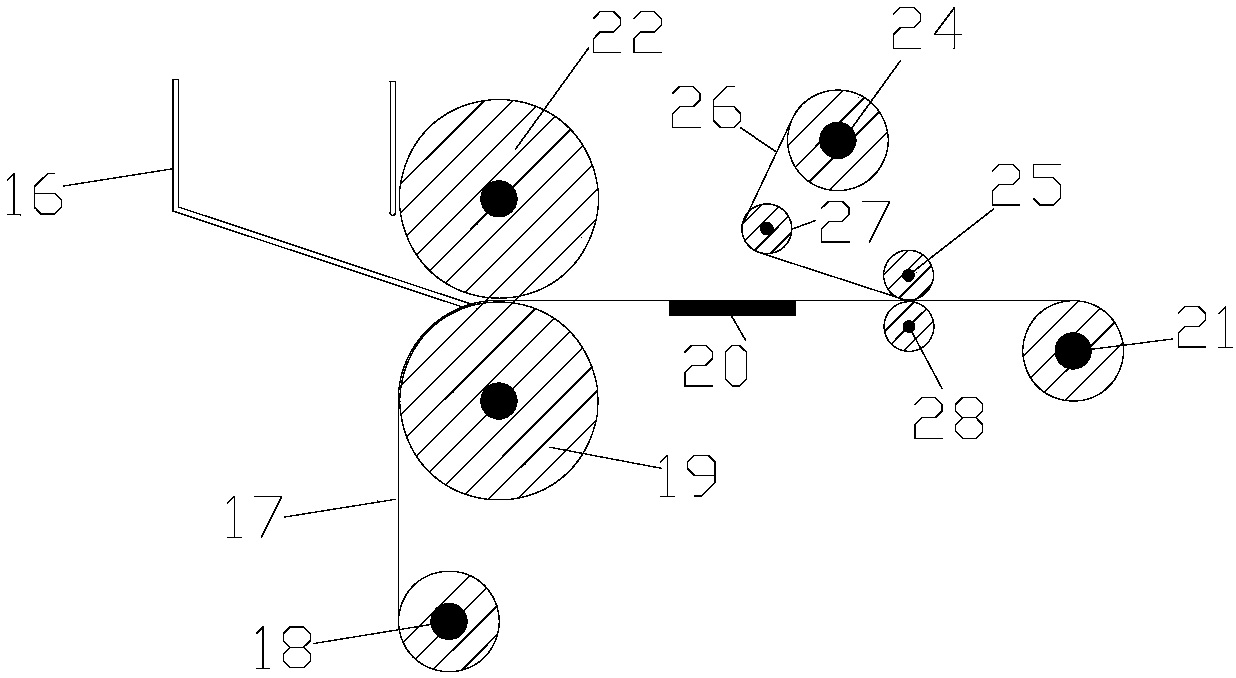

[0023] a) Put the main body resin of the fireproof coating in the glue tank of the film coating equipment, and coat it on the release paper to form a continuous fireproof film;

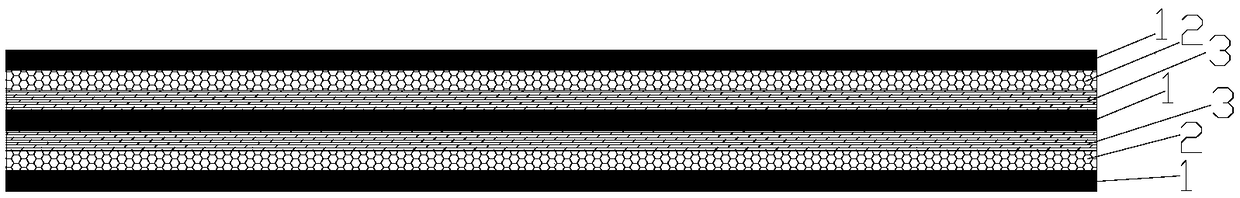

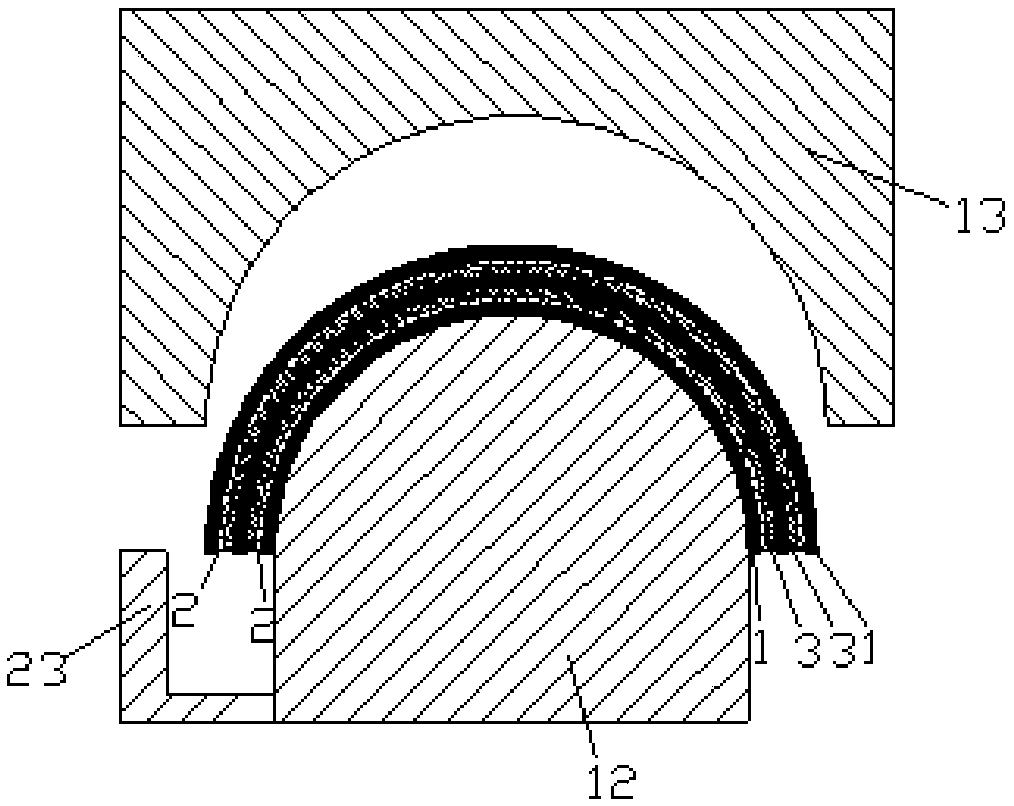

[0024] b) Lay materials on the mold, the laying order is: aluminum alloy plate, fireproof film, glass fiber prepreg layer, aluminum alloy plate, glass fiber prepreg layer, fireproof film, aluminum alloy plate to form parts preformed body;

[0025] c) Give the green body pressure and temperature to solidify the green body on the mold.

[0026] The thickness of the aluminum alloy plate is 0.2-0.5mm, and the glass fiber prepreg layer is composed of multiple layers of glass fiber prepreg. The nominal thickness of the glass fiber prepreg single layer is 0.125mm-0.200mm. Cured at 115°C to 125°C, the glass fiber volume fraction is 60% to 70%.

[0027] The thickness of the fireproof adhesive film is 0.2mm~0.3mm, and it is laid on the inner side o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com