Method for correcting system error during splicing sub-aperture

A technology of sub-aperture stitching and systematic error, which is applied in the field of optical measurement, can solve the problems of rising stitching error, complicated method, and no correction of systematic error, so as to achieve the effect of improving accuracy, enhancing robustness, and reducing the influence of systematic error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

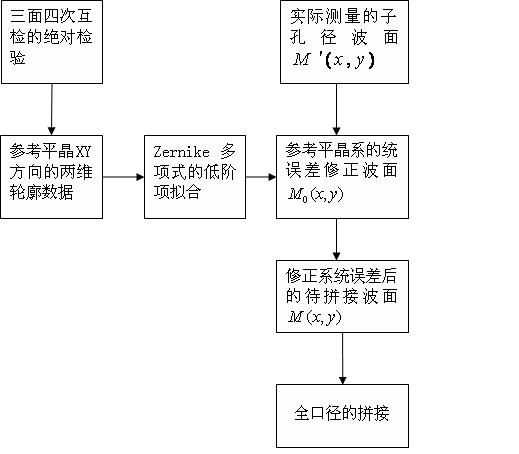

[0018] The invention is mainly used to solve the system error caused by the shape error of the reference flat crystal when the sub-aperture splicing method is used to detect the large-diameter optical mirror surface and the problem of the amplification of the system error. combine figure 1 , the present invention is a method for correcting systematic errors in sub-aperture stitching, comprising the following steps:

[0019] Step 1. Use the three-sided four-time mutual inspection method to carry out the absolute inspection of the surface shape of the reference flat crystal, thereby obtaining the line profile data of the reference flat crystal in two vertical directions passing through its center; preferably using two auxiliary flat crystals to perform three-sided four-sided inspection. Absolute checks for mutual checks.

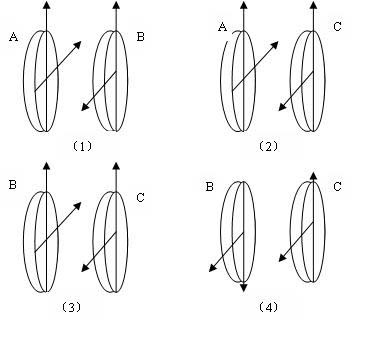

[0020] Such as figure 2 As shown, two auxiliary flat crystals B and C are used to perform absolute inspection of three sides and four mutual inspections on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com