Cathode wire structure for magnetron

A cathode wire and magnetron technology, applied in the field of magnetrons, can solve the problems of harsh selection of raw materials for connecting pieces, high metal material costs, increased production costs, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

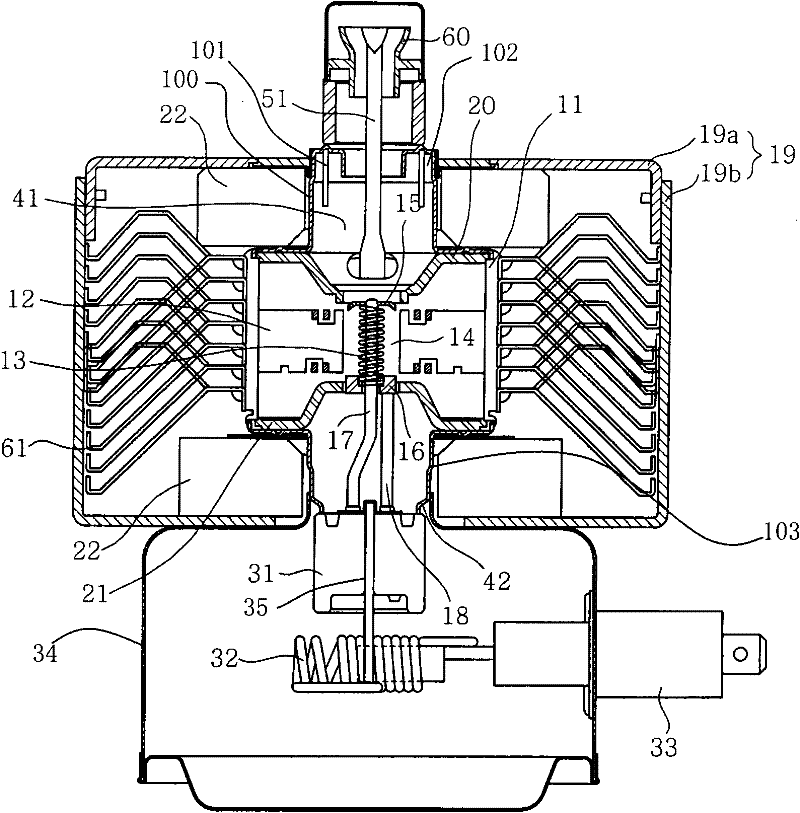

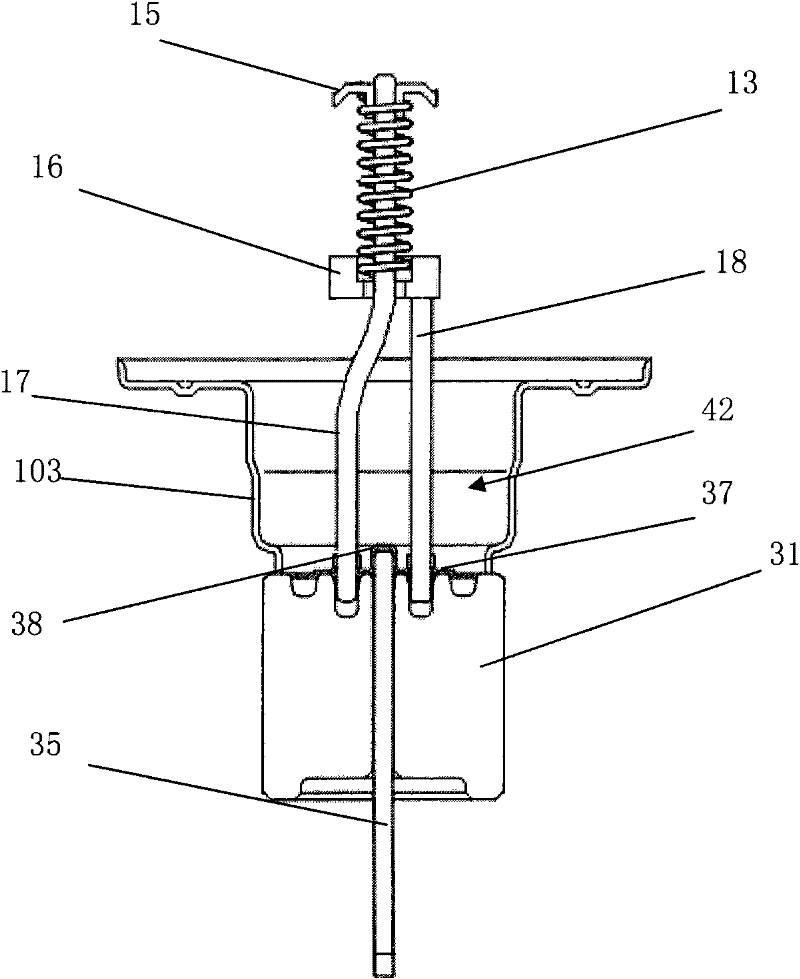

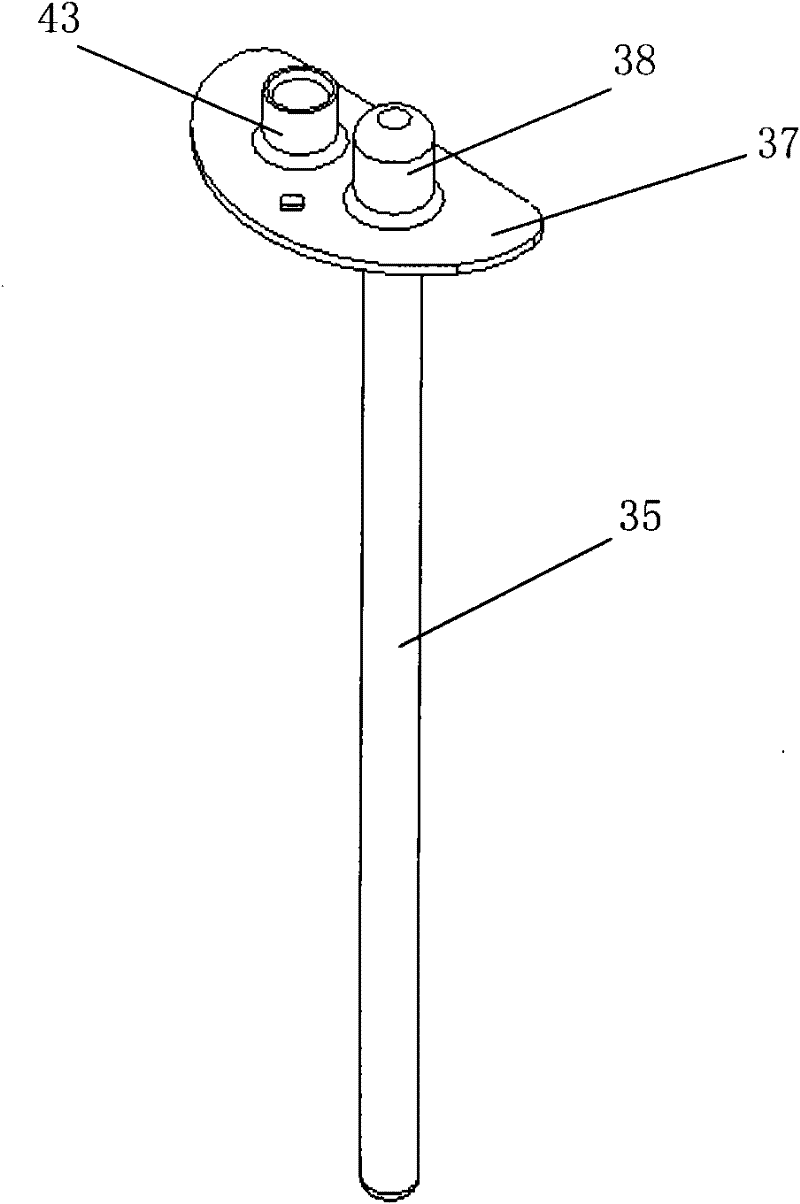

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0034] Figure 5 It is a schematic diagram when the cathode lead-out wire and the connecting piece are fixed to each other in the cathode wire structure of the magnetron of the present invention; Figure 6 It is a schematic diagram of the connecting piece in the cathode wire structure of the magnetron in the present invention; Figure 7 It is a schematic diagram of the cathode lead-out wire in the cathode wire structure of the magnetron in the present invention.

[0035] like Figure 5 to Figure 7As shown, the cathode cover of the magnetron is arranged at the lower part of the lower magnetic pole of the magnetron, and is sealed and connected with the anode shell of the magnetron to form a lower sealed chamber. The metal cathode cover and the anode shell are tightly connected by welding, and the cathode seal The middle position of the lower part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com