Reducible relief opening

A kind of impeller pump, working technology, applied in the components of the pumping device for elastic fluid, pump control, non-variable pump, etc., can solve the problem of slip ring seal damage, etc., and achieve the effect of reliable mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

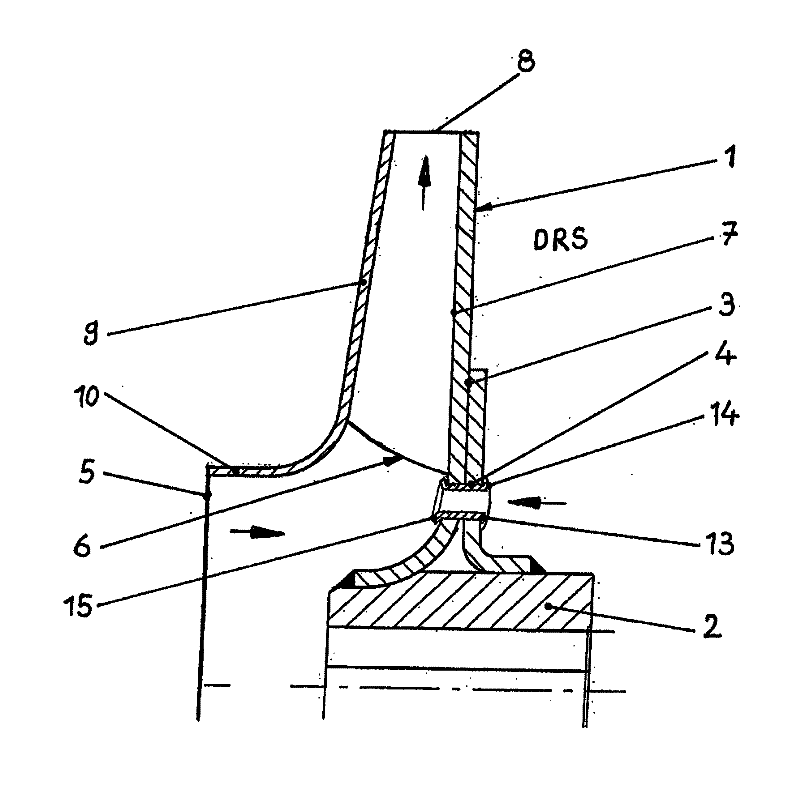

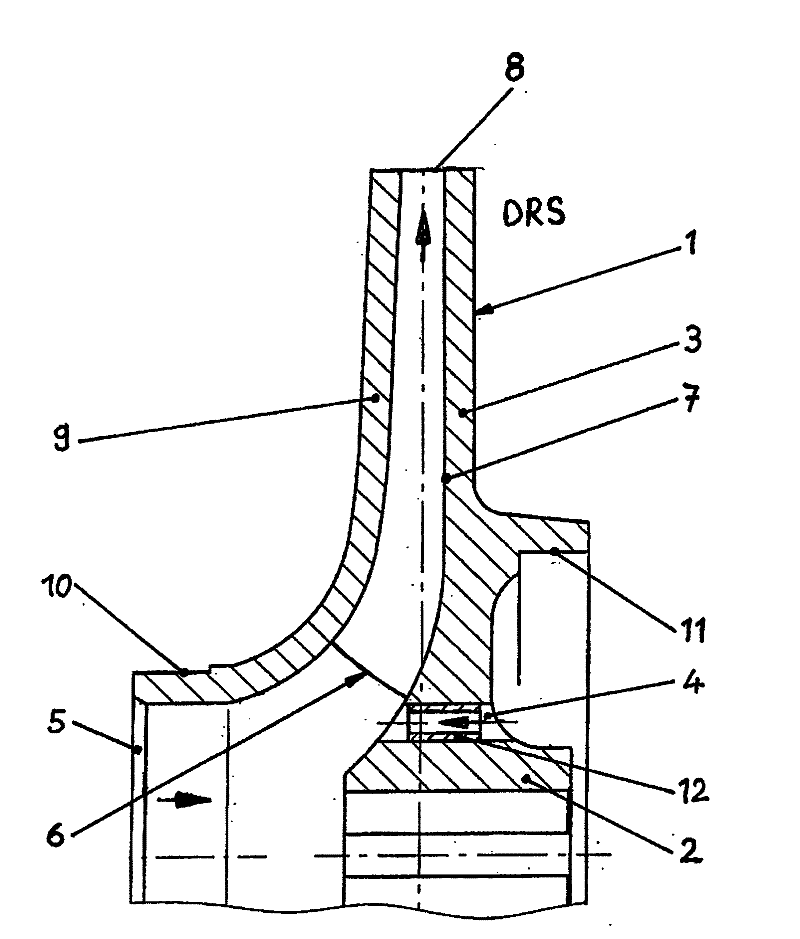

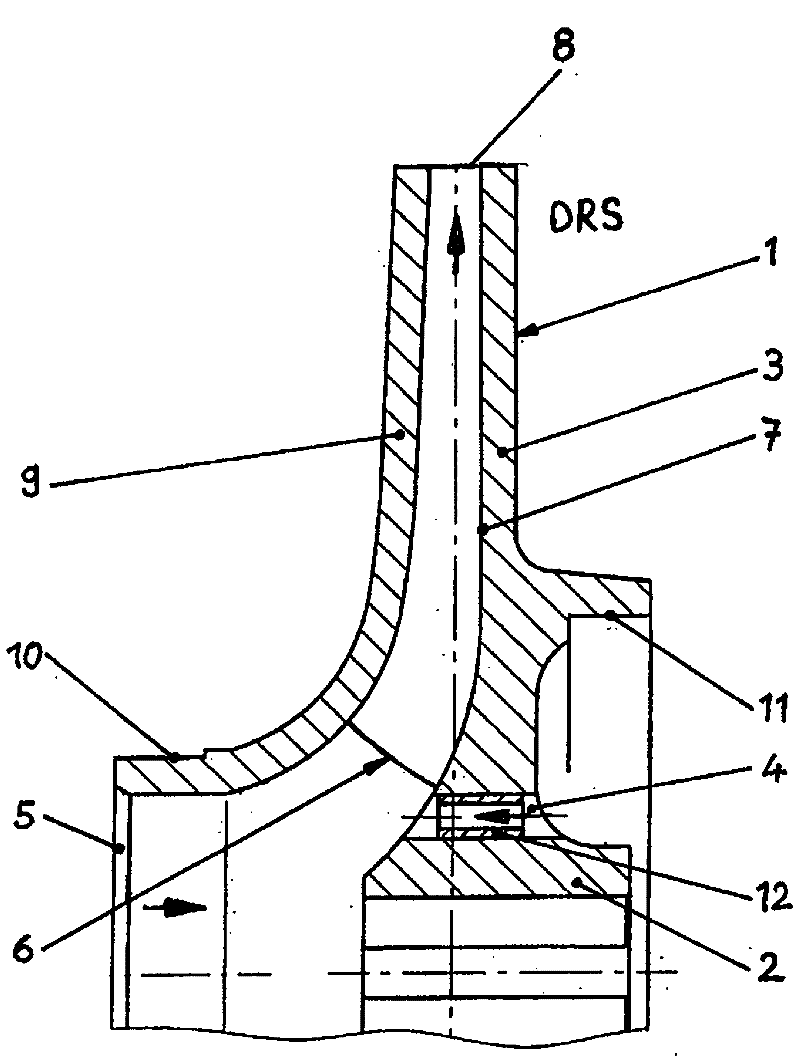

[0013] figure 1 A vane pump impeller is shown in radial and closed construction. The housing housing the impeller 1 as well as the shaft driving the impeller 1 via the hub 2 and the shaft seal are not shown for greater clarity. The rotor wheel 1 made of a cast part has a pressure-side rotor cover plate 3 which, at the transition to the hub 2, is equipped with a plurality of diametrically distributed relief openings 4 . They often consist of holes.

[0014] The fluid delivered from the impeller 1 flows from the impeller inlet 5 through the vane channels 7 delimited by the vanes 6 to the impeller outlet 8 and is discharged into the interior of the housing. The pressure inside the housing at the impeller outlet 8 acts and exerts a force in the axial direction both on the pressure-side impeller cover plate and on the opposite suction-side impeller cover plate 9 . Due to the different sizes of the working impeller cover disk area, a derived axial force is generated by the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com