Conduit oil outlet throttling structure and fuel oil prefilter shell assembly

An oil outlet and conduit technology, which is applied to the throttling structure of the conduit oil outlet and the fuel pre-filter housing assembly field, can solve the problem of reducing the service life of the filter element, reducing the pressure difference between the inside and outside of the exhaust hole, and affecting the fuel fluid. face and other issues to achieve the effect of ensuring utilization, smoothness, and smooth transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

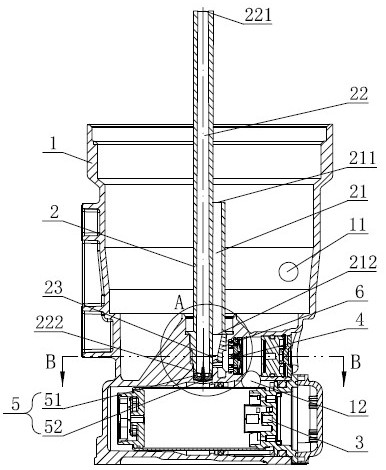

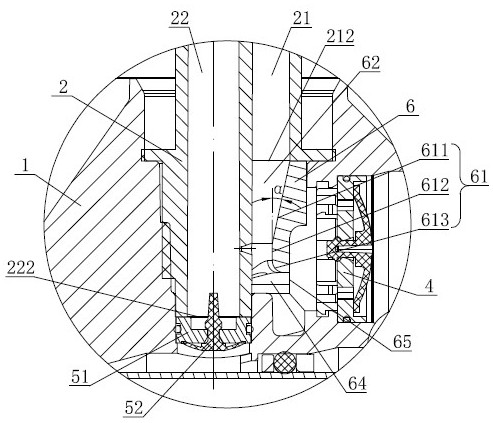

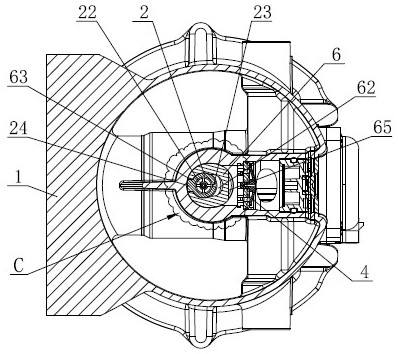

[0048] like figure 1 As shown, the housing 1 of the present invention is provided with an oil inlet pipe port 11 and an oil outlet pipe port 12, and the housing 1 is provided with a conduit 2, an electric pump 3 and a first one-way valve assembly 4; the conduit 2 is vertically inserted into the In the center of the casing 1 , the electric pump 3 is horizontally inserted under the conduit 2 , and the first check valve assembly 4 is arranged between the conduit 2 and the outlet pipe 12 , and can be unidirectionally opened toward the outlet 12 .

[0049] like figure 1 , figure 2 As shown, the conduit 2 is vertically provided with a fuel passage 21 and an air flow passage 22 through which the upper port of the fuel passage 21 is an oil inlet port 211, the lower port is an oil outlet port 212, and the upper port of the air flow passage 22 is an air intake port 221, The lower port is the air outlet port 222; the height of the oil inlet port 211 of the fuel passage 21 is shorter t...

no. 2 example

[0053] like Figure 7 As shown, different from the first embodiment, the throttling structure of this embodiment is directly integrally formed on the conduit 2 . On the conduit 2, located below the fuel passage 21, a throttle pipe portion 25 extends downward in the axial direction, which is the same as the block 6 of the first embodiment. Oil port 64, the first throttling passage 62 between the first throttling surface 61 and the outer wall surface of the air flow channel 22; 612 and the first arc surface section 613, which is small at the top and large at the bottom, respectively form an upper flow section with a flow cross-sectional area gradually decreasing from top to bottom in the first throttling passage 62, and the flow cross-sectional area is constant and relatively Narrow middle flow section, and lower flow section whose flow area gradually increases from top to bottom.

no. 3 example

[0055] like Figure 8 As shown, different from the first embodiment, the second one-way valve assembly 5 of this embodiment is directly integrated on the conduit 2 . The air outlet port 222 of the air flow channel 22 of the conduit 2 is integrally formed with a valve seat portion 26, and several air flow holes (not shown in the figure) are vertically opened on the valve seat portion 26. The valve of the second check valve assembly 5 The sheet 52 is inserted vertically on the valve seat portion 26 and can be opened in one direction downward toward the electric pump 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com