Attenuator for damping pressure fluctuations in a hydraulic system

A hydraulic system and attenuator technology, applied in the direction of fluid pressure actuation devices, fluid pressure actuation system components, engine components, etc., can solve the problems of hydraulic system cavitation, harmful overpressure or underpressure pulse, etc. corrosion, reduce overvoltage and undervoltage pulses, improve the effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

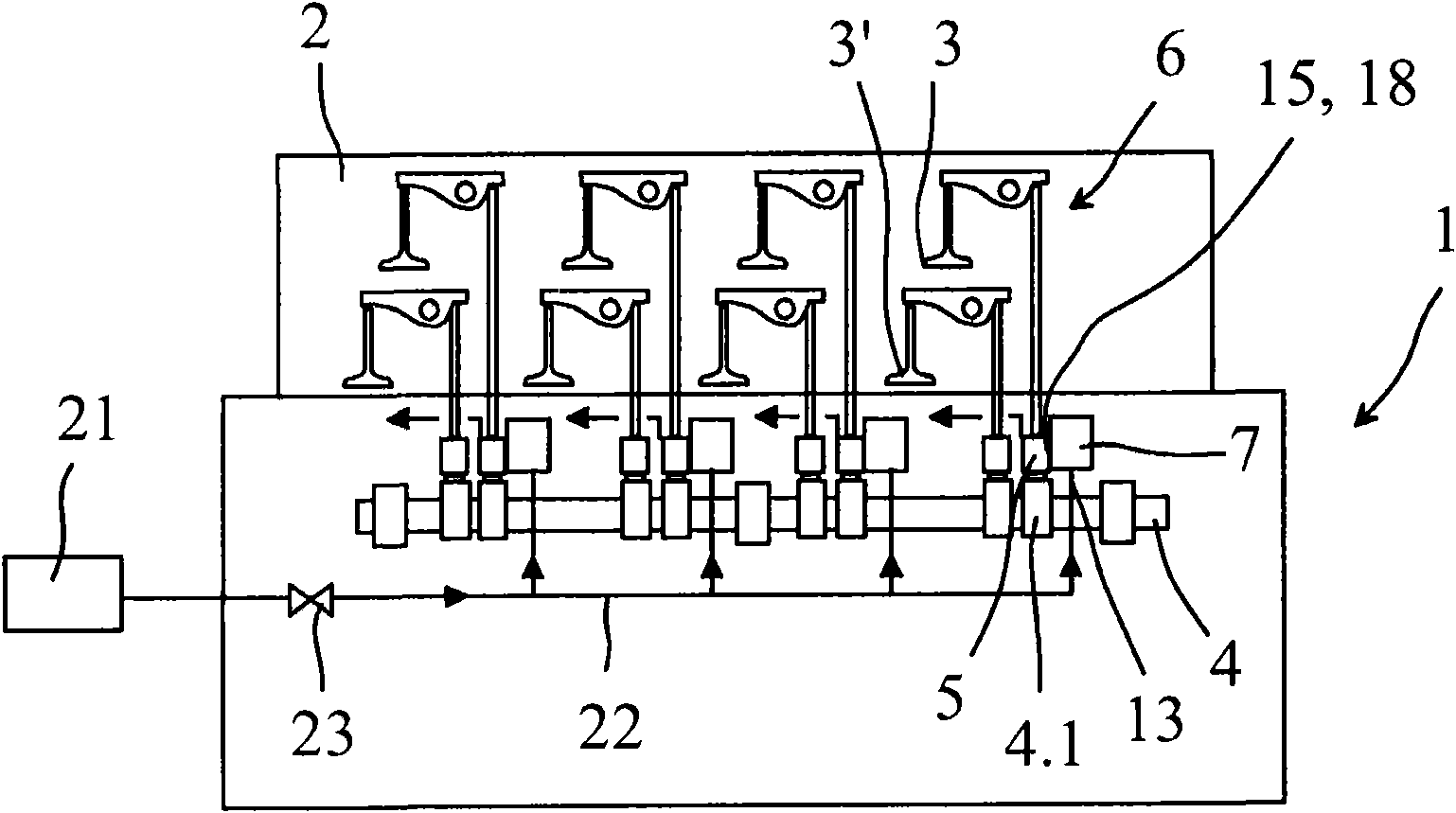

[0013] attached figure 1 A piston engine 1 is shown schematically, the gas exchange of the engine's cylinders (not shown) being directed by intake and exhaust valves 3, 3' located on the cylinder block 2. The valve 3 is operated by a valve train 6, receiving its operating force from the camshaft 4 of the engine, generally guided by the cam profile 4.1. The force transmission connection between each valve mechanism 6 is realized by a hydraulic control system or guide 5 .

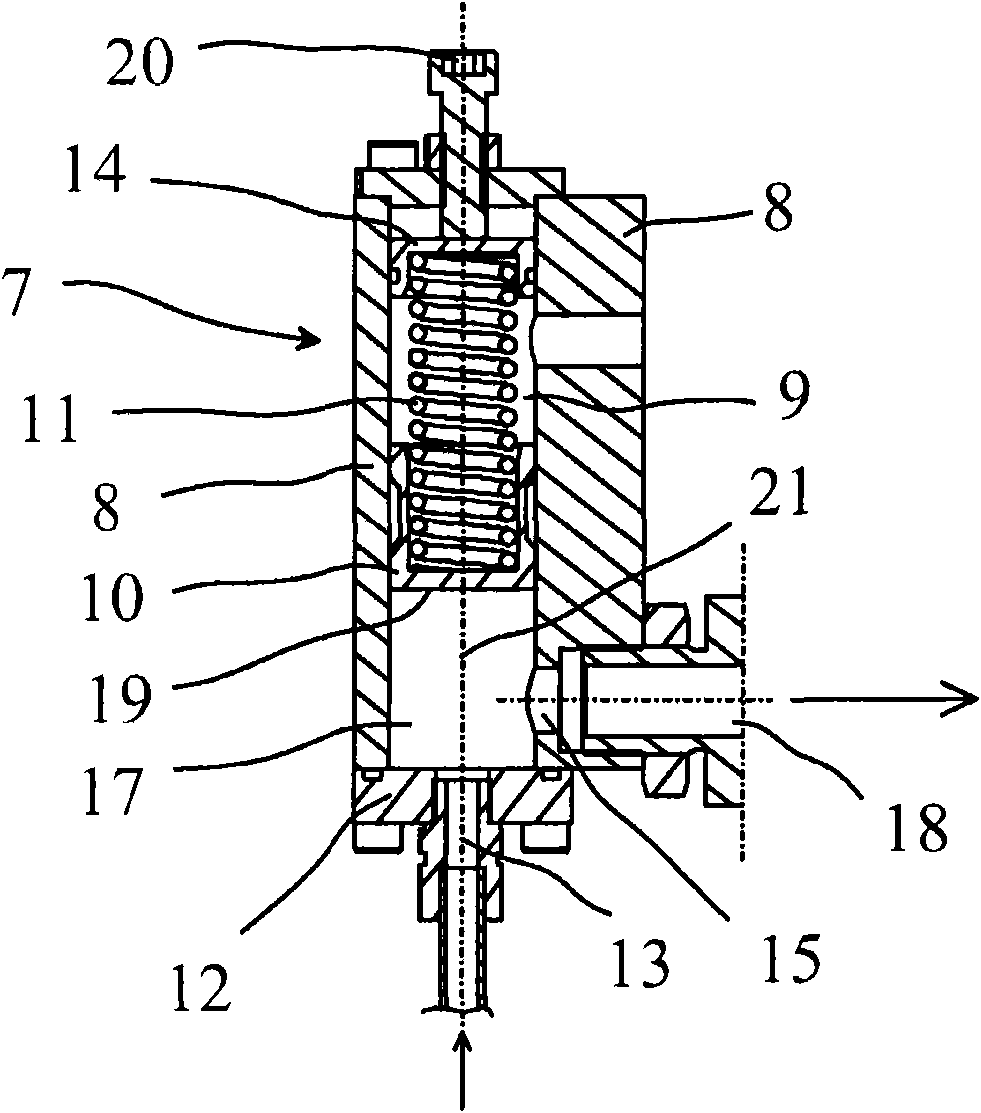

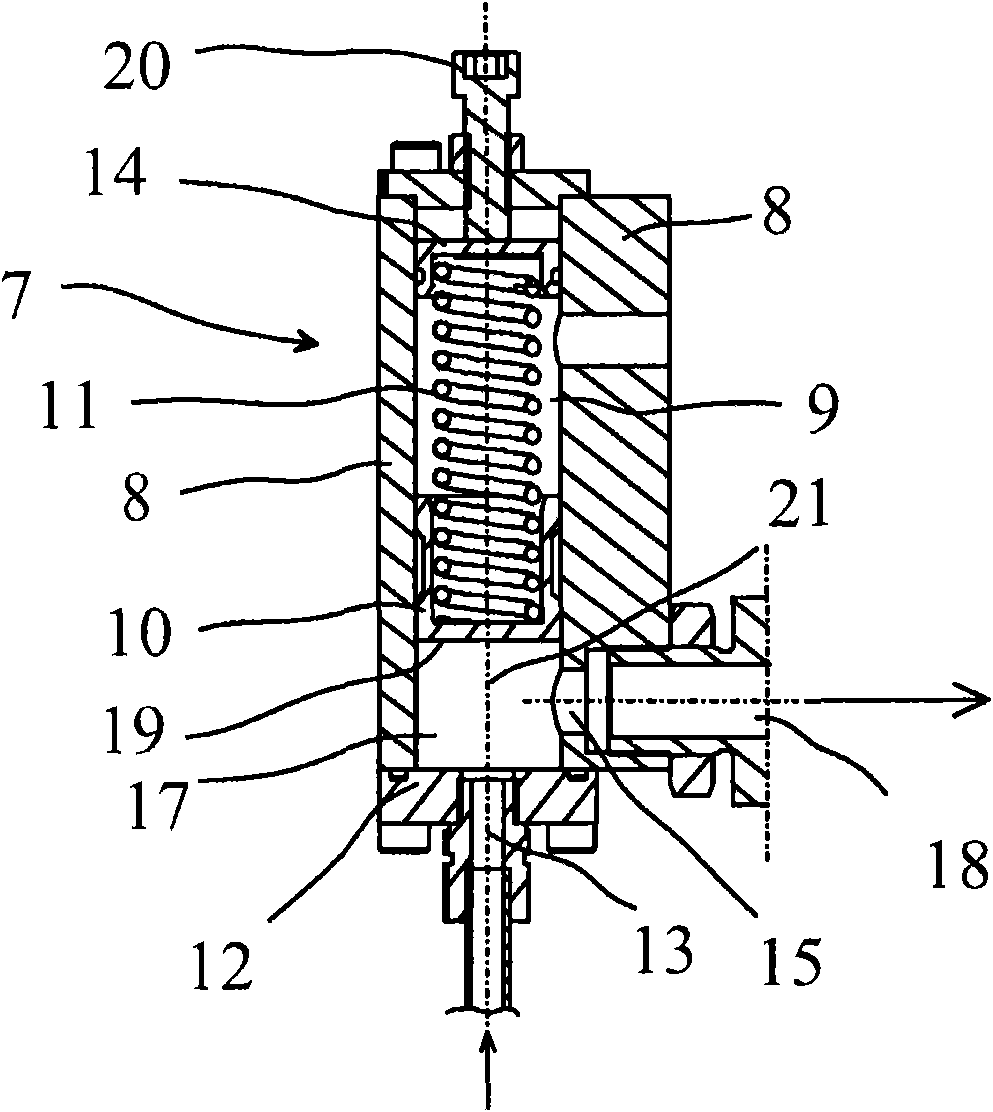

[0014] By means of the guide 5, the timing of the valves 3, 3', i.e. the moment of opening and closing during the working cycle of the cylinder, can be varied as desired. The guide 5 can be implemented in various ways. In one embodiment, the guide 5 comprises a space for hydraulic fluid, which is connected to the hydraulic system via a supply channel 18 . The space surrounds the piston, which is in force-transmitting connection with the cams and the valve mechanism of the camshaft of the engine. By varyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com