Greenhouse heater

A heat booster and governor technology, applied in the heating field, can solve the problems of slow temperature rise and insufficient fuel utilization, and achieve the effects of full fuel combustion, no harmful gas, and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

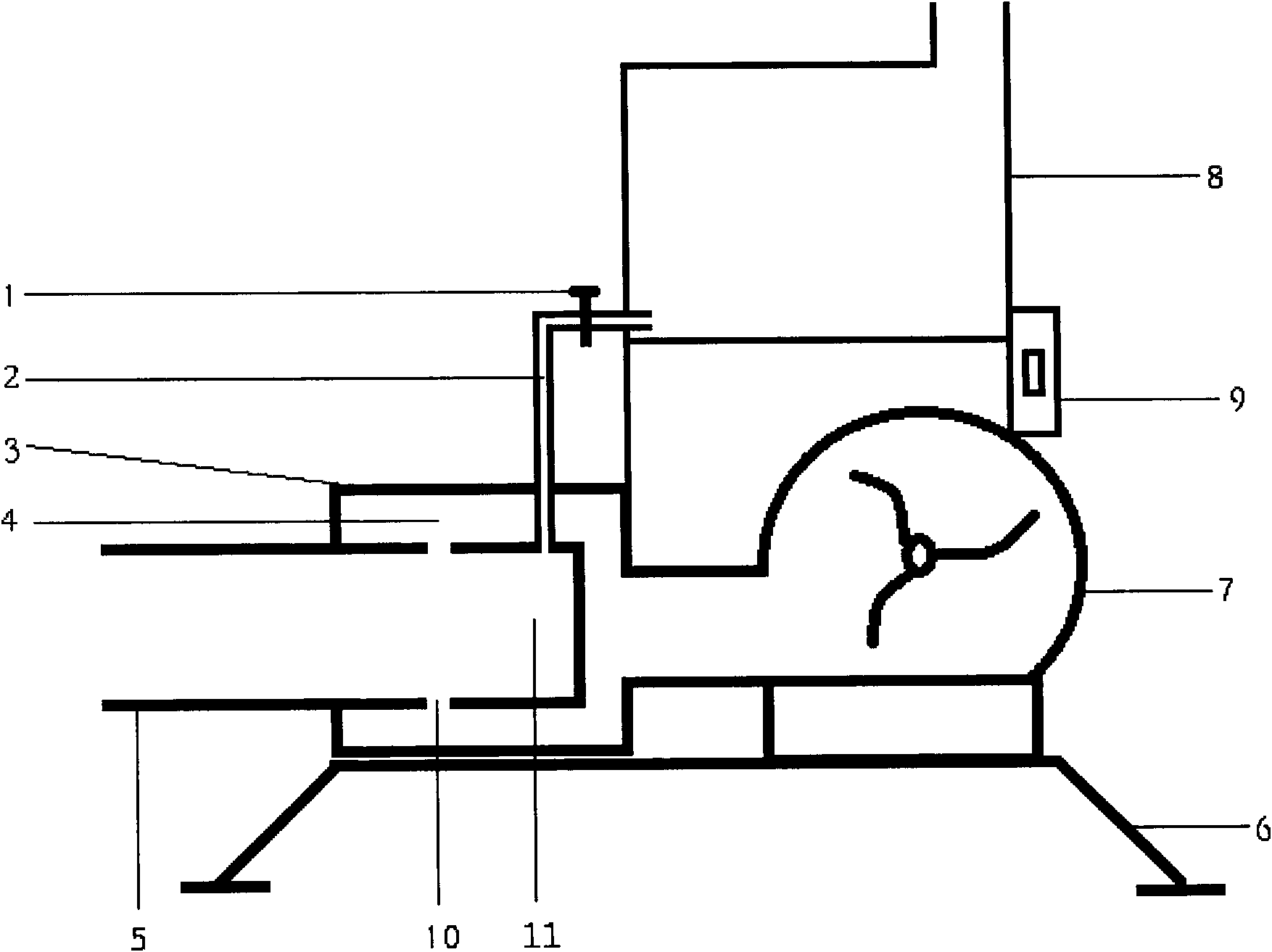

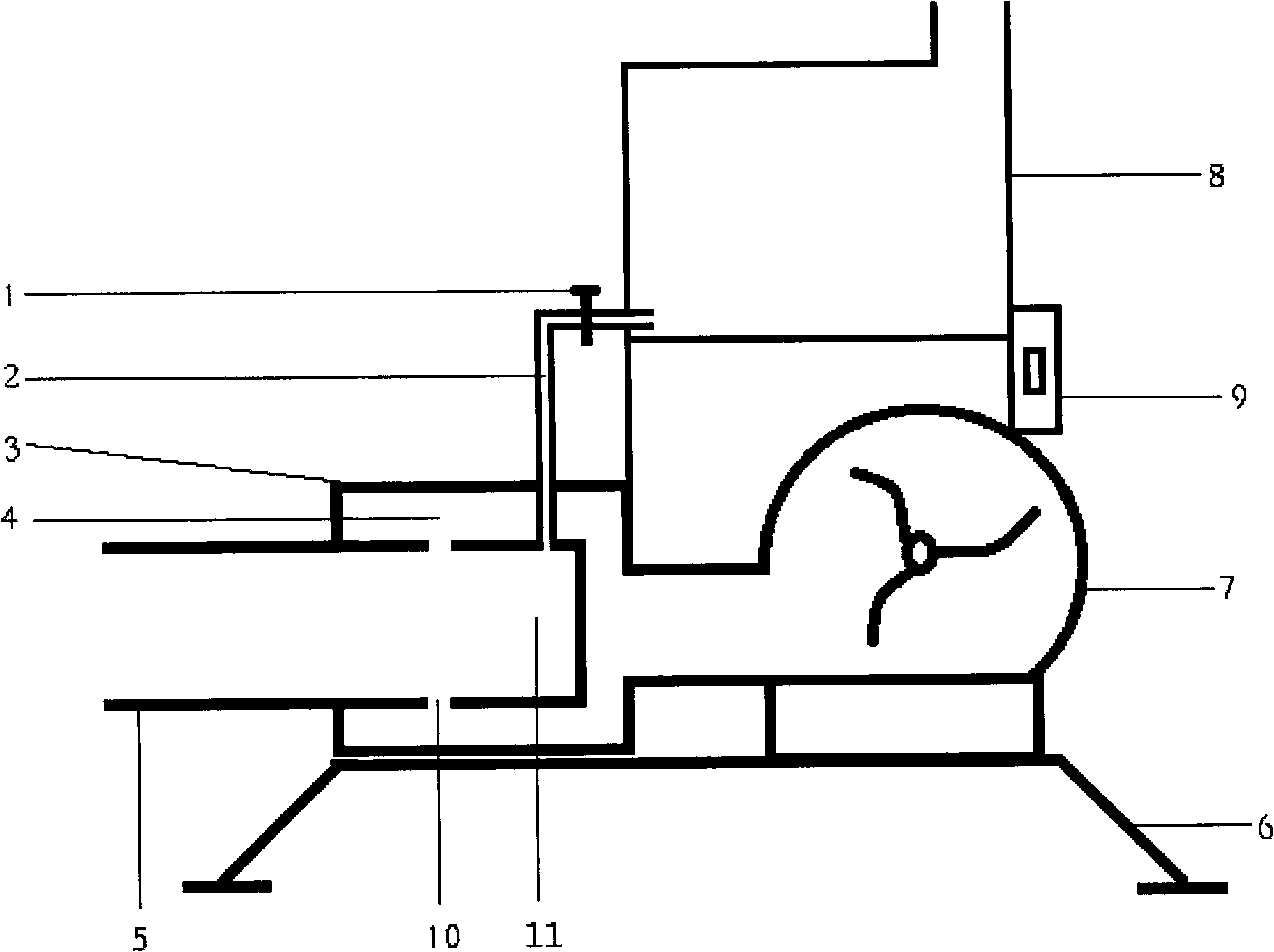

[0009] As shown in the figure, the fuel tank 8 is connected to the oil passage 2, and a switch 1 is provided between the two. The oil passage 2 is connected to the combustion chamber 11, and the air passage 4 and the combustion chamber 11 are connected through a circle of air inlets 10, and the combustion chamber 11 The end is provided with a fire outlet 5, the air duct 4 communicates with the fan 7, and the fan 7 is provided with a speed regulator 9, and the bottom is a bracket 6.

[0010] The present invention mainly uses alcohol as fuel, turn on the switch 1, and at the same time ignite the paper and put it into the combustion chamber 11, turn on the fan 7, adjust the switch 1 to adjust the fuel injection rate, and adjust the governor 9 to adjust the wind speed of the fan 7 to When the alcohol reaches its best burning state, the heating process starts. Greenhouse warmer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com